A Water Pipelines Leakage Detection System

Pipeline leakage is a routine challenge in water supply systems that has negative impacts on the environment, economy, and society. That's why pipeline monitoring and leakage detection are key matters.

The audio-audio method and the sonic method are among the old methods of leakage detection that depend on the existence of operators and therefore require a lot of money and time. In addition to meeting urban and industrial water needs in other industries and hydraulic exploration, there is a need to detect pipeline leakages.

Currently, the best way to monitor leakages is district metering area (DMA).

In this method, the flow and pressure nodes in each DMA can be remotely monitored. Consequently, the unusual water supply of the pipeline can be figured out on time and the leakage can be detected.

Here is the need for a system to collect information about pipeline flow and pressure. For this purpose, electromagnetic flowmeters and pressure transmitters are used, respectively. The resulting data is transmitted to the big data platform via a wireless monitoring terminal via the 4G network. The system is equipped with real-time alerts that send alerts to employees when needed through mobile phones or online monitoring platforms.

Sometimes, employees need to retrieve data from different times. This system fulfills this need with the possibility of data storage.

Other features of the newly designed electromagnetic flowmeter:

• In the sensor part, only the lining and the electrode have contact with the medium. As long as the electrode and the lining material are reasonably chosen, they can tolerate corrosion and wear, ensuring a long-term use.

• Explosion-proof / sanitary / CE

• Flow can be with temperature detection or pressure detection

• Unique electrode and lining process

• Several signal outputs: wireless output, digital signal, analog signal, and wired output.

• They can withstand as much pressure as 25MPa.

Features of newly designed Pressure Transmitters:

• 4mA ~ 20mA DC two-wire current output

• RS485 communication interface or HARTâ communication protocol (optional) supports networking applications

• -10 ~ ~ 70 ℃ digital wide temperature compensation

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

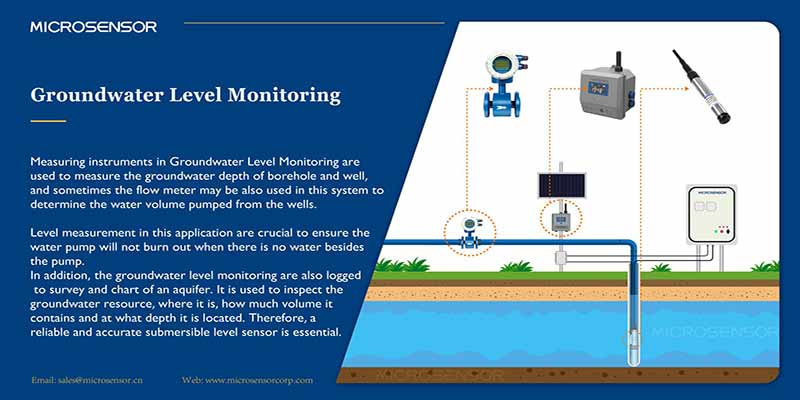

Monitoring Groundwater Level

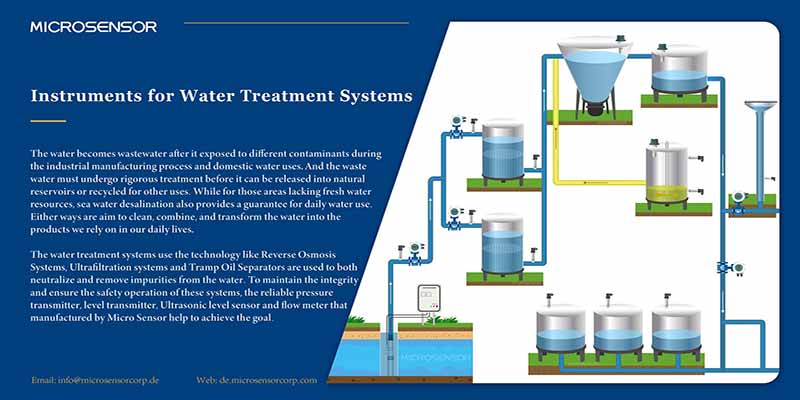

Tools for the Systems of Water Treatment

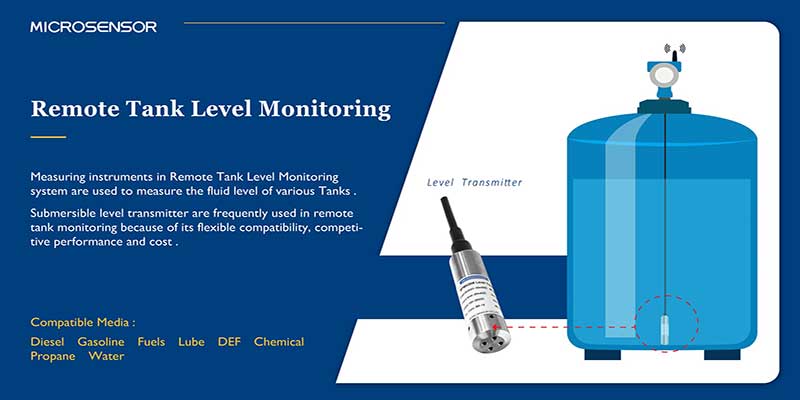

Remote Monitoring of the Fluid Level of Tanks

Related Products