A Comprehensive Guide to Pressure Sensor Maintenance

Welcome to the dazzling world of pressure sensors, where precision meets perfection! These tiny yet powerful devices work behind the scenes, measuring pressure with a finesse that's both awe-inspiring and essential to countless industries.

Picture this: within these unassuming sensors lies the magic of accuracy, quietly ensuring that everything from industrial machinery to medical devices operates flawlessly. They're the unsung heroes, the guardians of precision, bringing reliability to every pressure-dependent process.

But wait, there's more! These sensors aren't just about accuracy; they're user-loving marvels. Their sleek designs and cutting-edge technology make them adaptable, reliable, and, dare I say, quite glamorous in their functionality. From aerospace marvels to medical miracles, pressure sensors take center stage in ensuring the world runs smoothly.

So, buckle up for a journey through a world where precision meets elegance, where these sensors, unassuming as they are, play a pivotal role in making our lives easier and our systems more efficient.

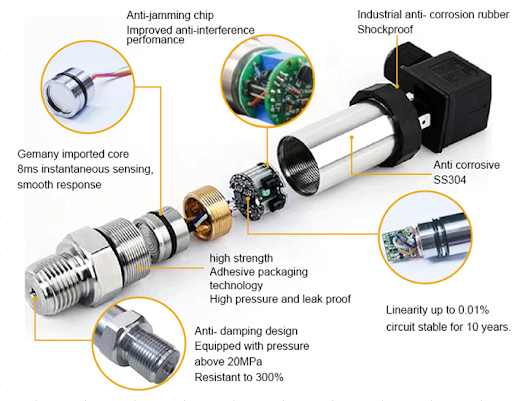

Fig 1. Pressure sensor parts

What is the pressure sensor maintenance?

Pressure sensor maintenance involves a series of proactive actions aimed at preserving the accuracy, reliability, and longevity of these devices. Regular maintenance routines typically include several key steps. Firstly, inspection for physical damage or wear is crucial. This involves examining the sensor housing, connections, and any exposed components for signs of corrosion, leaks, or mechanical stress. Cleaning is another fundamental aspect, ensuring that any contaminants or debris that might affect sensor accuracy are removed using appropriate cleaning agents and methods recommended by the sensor manufacturer. Regular cleaning prevents the buildup of substances that could interfere with the sensor's functionality or accuracy over time.

Beyond visual inspections and cleaning, calibration verification is a critical maintenance task. Calibration confirms that the sensor's output corresponds accurately to the pressure being measured. Regularly checking the sensor against a known reference standard ensures it maintains its precision. Additionally, some sensors might need specific tests or adjustments to reset or recalibrate their zero point to accurately measure pressure variations. These routine maintenance practices are essential for ensuring that pressure sensors continue to provide accurate readings, operate reliably, and contribute to the safety and efficiency of the systems they're integrated into.

Why is maintenance important for pressure sensors?

Maintenance is crucial for pressure sensors due to several key reasons:

What are the pressure sensor maintenance steps?

Pressure sensor maintenance involves several essential steps to ensure accurate readings and optimal performance:

What are the steps of Visual Inspection?

Visual inspection of pressure sensors involves a methodical examination to identify any physical damage, wear, or irregularities that could impact their performance. The steps for visual inspection encompass scrutinizing various aspects of the sensor:

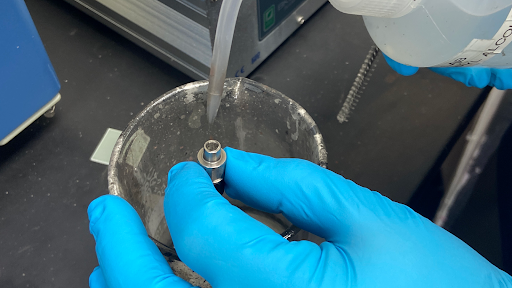

Fig 2. Visual inspection

Important Tips about Visual Inspection

Here are some crucial tips to keep in mind when conducting visual inspections for pressure sensors:

How can clean a pressure sensor?

Cleaning a pressure sensor requires careful handling to prevent damage to its sensitive components. Here are steps to clean a pressure sensor:

Fig 3. Add solvent into the pressure sensor to clean it

Safety tips about cleaning a pressure sensor

Safety is paramount when cleaning a pressure sensor to prevent accidents or damage to sensitive components. Here are some key safety tips:

What is the equipment used in pressure sensor cleaning?

Cleaning pressure sensors typically involves using specific equipment and materials to ensure proper and safe maintenance. Here's a list of commonly used items for cleaning pressure sensors:

Fig 4. As you push the brush in, the material should exit the opposite side of the sensor

Can pressure sensors be cleaned without removal from the system?

Yes, in many cases, pressure sensors can be cleaned without requiring removal from the system, depending on the sensor's design and accessibility. Cleaning in place is often feasible and involves careful procedures to ensure effective cleaning without disrupting the system's operation.

Using approved cleaning agents or solvents and appropriate cleaning tools, technicians can access the sensor within the system, carefully clean its exterior surfaces, and remove any accumulated contaminants. However, it's crucial to follow manufacturer guidelines and safety protocols to prevent damage to sensitive components or interference with the sensor's functionality during the cleaning process. Additionally, certain cleaning methods might be limited by the system's design or accessibility, necessitating removal for thorough cleaning in specific cases where in-place cleaning is not feasible.

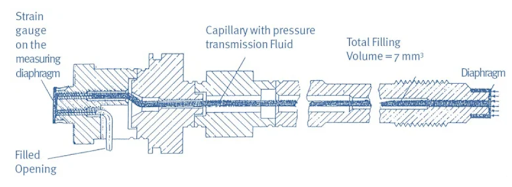

Calibration Verification of the Pressure Sensor

Calibration verification is a critical step in ensuring the accuracy and reliability of pressure sensors. This process involves comparing the sensor's output readings to a known standard or reference to confirm its calibration and accuracy.

Firstly, begin by selecting a reliable and traceable reference standard. This could be a certified pressure gauge or a calibrated instrument with a known accuracy that closely matches or exceeds the sensor's specifications. Next, connect the pressure sensor and the reference standard to a controlled environment or calibration setup where pressure variations can be applied accurately and consistently.

Once both the sensor and the reference standard are connected, apply known pressure values incrementally across the desired range. Record and compare the readings from the sensor with the readings obtained from the reference standard. Assess the differences between the sensor's measurements and the reference values. If the sensor's readings deviate significantly from the reference standard, it indicates a potential calibration error or drift, signaling the need for recalibration or adjustments.

Document the calibration verification process, including the pressure values applied, corresponding sensor readings, and any observed deviations. Regular calibration verification helps identify any shifts in accuracy over time and allows for corrective action to maintain the sensor's precision. By conducting this verification periodically, you ensure that the pressure sensor continues to provide accurate and reliable measurements within its operational range.

What are the signs that a pressure sensor needs recalibration?

Several signs can indicate that a pressure sensor might require recalibration:

Fig 5. Pressure gauge manual calibration

When should re-calibrate a pressure sensor?

The ideal frequency for recalibrating a pressure sensor depends on various factors, including the sensor's type, application, environment, and manufacturer's recommendations. However, several common scenarios signal the need for recalibration:

How often should pressure sensors be recalibrated?

The frequency of recalibration for pressure sensors can vary based on several factors:

What are the Re-calibration intervals and procedures?

The recalibration intervals and procedures for pressure sensors depend on various factors, including the sensor type, application, environmental conditions, and manufacturer's recommendations. Here's a general overview:

Re-calibration Intervals:

Can the pressure sensor be re-calibrated manually?

Calibrating a pressure sensor typically involves precise adjustments to ensure accurate measurements. Manual calibration, while feasible in some cases, might not be the most accurate or efficient method due to the precision required for calibration.

Manual calibration involves adjusting the sensor's settings or parameters using calibration tools and adjusting screws, or controls provided by the sensor's design. However, manual methods might not provide the level of precision needed for highly accurate measurements, especially in sensitive or high-precision applications.

In many instances, pressure sensors are calibrated using specialized calibration equipment or software that offers higher precision and accuracy. These tools ensure precise adjustments based on known standards or reference values to achieve accurate and reliable sensor readings.

While manual calibration might be possible for some pressure sensors, particularly those with accessible calibration controls, it's essential to consider the sensor's specifications, manufacturer recommendations, and the required accuracy level. Professional calibration services or manufacturer-recommended calibration methods often provide the most accurate and reliable results for recalibrating pressure sensors.

What are important tips for re-calibration of pressure sensors?

Certainly! Re-calibration of pressure sensors is crucial for maintaining accuracy and reliability. Here are some important tips to consider:

How can test a pressure sensor function?

Testing the function of a pressure sensor involves verifying its ability to accurately measure pressure variations. Here's a step-by-step guide to testing a pressure sensor's function:

What are the important functional tests for pressure sensors?

Performing comprehensive functional tests is crucial to ensuring the accurate and reliable operation of pressure sensors. Here are some important functional tests to consider:

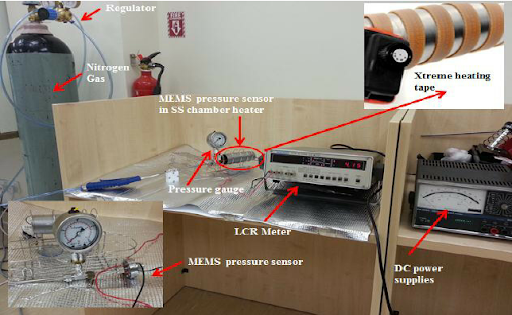

Fig 6. Experimental set-up for packaged pressure sensor testing

Which test should always be done?

While all functional tests are essential for a comprehensive assessment of a pressure sensor's performance, one test that should always be conducted is the Zero Point Calibration test.

The Zero Point Calibration verifies the sensor's ability to accurately measure zero pressure or the absence of pressure. It ensures that the sensor's output corresponds correctly to no applied pressure, establishing a reliable baseline reference. This test is crucial as it confirms the sensor's initial state and its ability to provide accurate readings when no pressure is applied.

If the Zero Point Calibration test fails or shows significant inaccuracies, it could indicate issues with the sensor's baseline reference or zero-point drift. An inaccurate zero point can lead to errors in pressure measurements across the sensor's entire range. Therefore, verifying the sensor's zero-point accuracy is fundamental for ensuring the reliability of subsequent pressure measurements.

Apart from this, all other functional tests recommended by the manufacturer based on the sensor's specifications, application, and operating environment should also be performed to evaluate the sensor's performance comprehensively. Each test serves a unique purpose in confirming the sensor's accuracy, stability, and responsiveness in various operating conditions.

Documentation and Record-Keeping of pressure sensors

Documentation and record-keeping are integral parts of maintaining pressure sensors, ensuring their accurate performance, and facilitating troubleshooting. Here's an overview of their importance and key aspects:

Where documentation and record-keeping are used?

Documentation and record-keeping for pressure sensors are utilized across various industries and applications where these sensors are employed. Here are key areas where documentation and record-keeping are crucial:

What should be documented during pressure sensor maintenance?

During pressure sensor maintenance, comprehensive documentation is essential. The following aspects should be documented:

Fig 7. Pressure sensor maintenance

Periodic Review and Adjustment

Periodic review and adjustment of pressure sensors are essential maintenance practices aimed at ensuring their accuracy, reliability, and optimal performance over time. Here's an overview of this process:

How can review and adjust a pressure sensor periodically?

Periodic review and adjustment of pressure sensors involve systematic evaluations to ensure their accuracy and reliability. Here's a step-by-step guide on how to conduct this process:

What are the tips should observed about pressure sensor maintenance?

Certainly! Here are some essential tips to consider for pressure sensor maintenance:

Conclusion

Maintaining pressure sensors is crucial for their accuracy, reliability, and longevity across diverse applications. By adhering to manufacturer guidelines, and conducting regular cleaning, scheduled calibration, and functional tests, these sensors can consistently provide precise readings vital for safety, efficiency, and compliance.

Environmental considerations, careful handling, and meticulous documentation play pivotal roles in preserving sensor performance. Periodic reviews, adjustments, and a proactive approach to maintenance ensure the sensors remain dependable over time, reducing risks of failures and costly downtimes.

Ultimately, through proper maintenance practices, pressure sensors can continue to deliver accurate measurements, contributing to operational safety, cost-effectiveness, compliance with standards, and extended lifespans in various industries and applications. Regular care ensures these critical components operate optimally, supporting systems and processes with reliability and precision.

To recap

1. Why is maintenance important for pressure sensors?

Maintenance ensures pressure sensors remain accurate, reliable, and safe. It prevents inaccuracies due to environmental factors, wear, or contaminants, crucial for their proper function.

2. How often should pressure sensors be recalibrated?

Recalibration frequency depends on usage, environmental conditions, and manufacturer recommendations. Typically, sensors are recalibrated annually or bi-annually, but critical applications might require more frequent recalibration.

3. What maintenance tasks should be performed regularly?

Regular maintenance includes cleaning, functional tests, and periodic reviews. Cleaning removes contaminants, functional tests verify accuracy, and reviews identify deviations for timely adjustments.

4. What are the signs that a pressure sensor needs recalibration?

Significant deviations from expected readings during functional tests, observed inaccuracies, or changes in environmental conditions may indicate the need for recalibration.

5. How do you clean a pressure sensor?

Use approved cleaning agents or solvents with lint-free cloths or swabs. Gently wipe the sensor's exterior, avoiding direct contact with sensitive components.

6. What should be documented during pressure sensor maintenance?

Document maintenance dates, cleaning schedules, calibration results, functional test outcomes, observed deviations, and any adjustments made for future reference and trend analysis.

7. How can one verify if a pressure sensor is functioning correctly?

Functional tests involving applying pressure variations and comparing sensor readings to known standards or expected values help verify accurate sensor function.

8. What safety measures should be considered during maintenance?

Use proper personal protective equipment, isolate power sources, handle sensors delicately, and adhere to safety protocols, especially in hazardous environments.

9. Can pressure sensors be cleaned without removal from the system?

Yes, in some cases, sensors can be cleaned in place using approved cleaning agents and methods without removing them from the system.

10. What should one do if a pressure sensor consistently shows inaccurate readings?

If consistent inaccuracies persist, perform a thorough review, conduct functional tests, and consider recalibration or adjustments based on the findings.

References

https://www.meokonint.com/news/precautions-for-pressure-transmitter-maintenance/

https://www.sand.com.tr/Haber/121/Melt-Pressure-Sensor-Maintenance-And-Calibration.html?Lang=EN

https://www.azosensors.com/article.aspx?ArticleID=2210

https://docs.voltera.io/nova/maintenance/nova-mai...

https://www.ipec.ie/tag/visual-inspection/

https://www.ipec.ie/tag/visual-inspection/

https://tameson.com/pages/pressure-gauge-calibration

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025