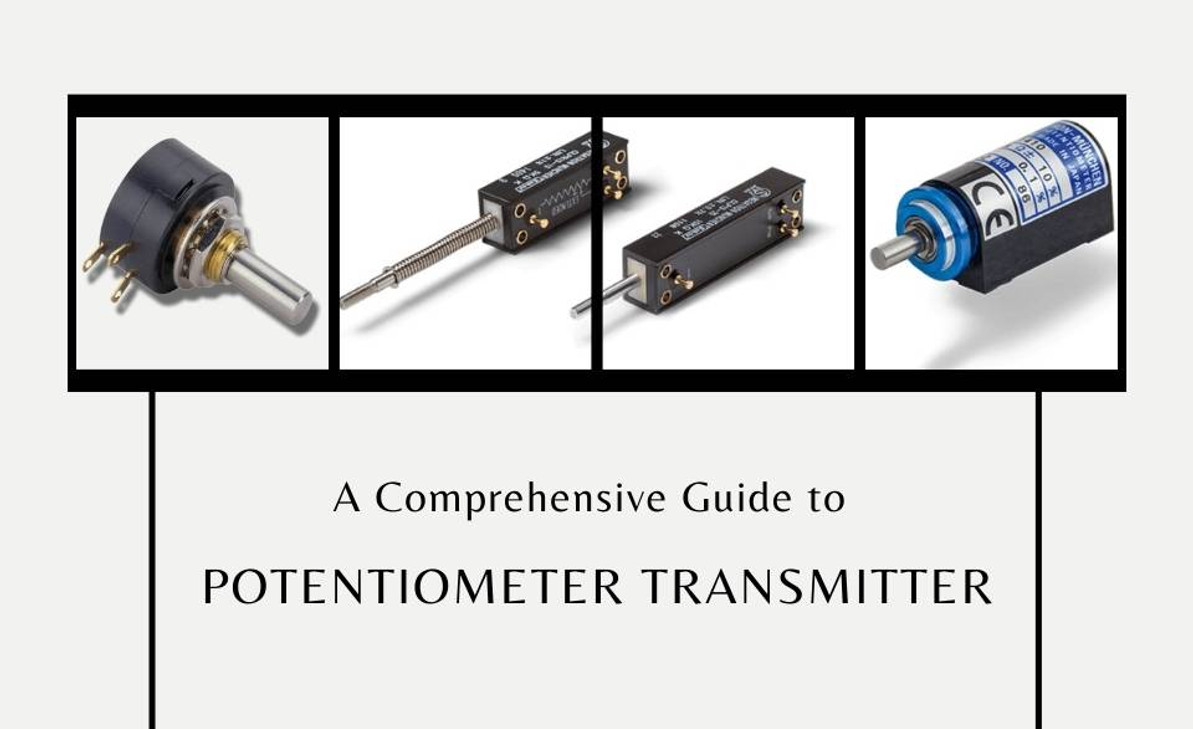

A Comprehensive Guide to Potentiometer Transmitter

Potentiometer transmitters are versatile devices that have found widespread applications in various industries, from aerospace and robotics to medical equipment and automotive industries. They measure the position or displacement of a moving object and convert it into an electrical signal. Potentiometer transmitters offer high accuracy, reliability, and cost-effectiveness, making them a popular choice for precise measurements. However, choosing the right potentiometer transmitter can be challenging, given the variety of options available. In this guide, we will explore the types, working principles, applications, and advantages and disadvantages of potentiometer transmitters. Additionally, we will provide tips on how to choose, install, and calibrate a potentiometer transmitter to get the most out of this powerful device.

History

The potentiometer, which is the underlying technology behind potentiometer transmitters, was first invented in the mid-19th century by Johann Christian Poggendorff, a German physicist. The potentiometer was originally designed as a tool for measuring electrical potential (voltage) in circuits, and it quickly became an important instrument in the field of electrical engineering.

Over time, engineers and scientists began to explore the potential applications of the potentiometer beyond measuring voltage. One of the first breakthroughs came in the early 20th century when the potentiometer was used as a position sensor in radio direction finders. This technology was critical for the development of early radar systems, which were used in World War II to detect and track enemy aircraft.

In the years following World War II, advances in electronics and manufacturing technology led to the development of more compact and reliable potentiometers. These new devices were used in a wide range of industrial and commercial applications, including robotics, automation, and control systems.

The first potentiometer transmitters specifically designed for industrial use were developed in the 1950s and 1960s. These devices were used to measure the position of mechanical components in industrial equipment, such as robotic arms and CNC machines. The potentiometer transmitter was particularly useful in situations where precise control of position or movement was required.

In the decades since potentiometer transmitters have continued to evolve and improve. Today, there are many different types of potentiometer transmitters available, each with its unique features and benefits. These devices are used in a wide range of applications, from aerospace and defense to automotive and consumer electronics.

What is a Potentiometer Transmitter?

A potentiometer transmitter is an electrical device used to measure the position or movement of mechanical components. It is essentially a variable resistor that is designed to respond to changes in position or movement and convert these changes into electrical signals that can be read and analyzed by electronic devices. The potentiometer transmitter consists of a resistive element, typically made of a conductive material such as carbon or metal, and a sliding contact or wiper that moves along the length of the resistive element. The position of the wiper along the resistive element determines the resistance of the potentiometer, which can be measured and used to determine the position or movement of the component being monitored.

Fig 1. Linear Potentiometer Transmitter

Potentiometer Transmitter Working Principle

The structure of a potentiometer transmitter consists of a resistive element and a sliding contact or wiper that moves along the length of the resistive element. The resistive element is typically made of a conductive material such as carbon or metal, and it is designed to provide a variable resistance depending on the position of the wiper.

Fig 3. Rotary transmitter working principle

The resistive element is usually in the form of a thin, flat strip that is mounted onto a non-conductive base. The wiper is typically made of a conductive material, such as metal, and it is attached to a mechanical component that moves in response to changes in position or movement. As the wiper moves along the resistive element, it changes the resistance of the potentiometer, which can be measured and used to determine the position or movement of the component being monitored.

In some potentiometer transmitters, the resistive element is a wire that is wound in a spiral pattern around a cylindrical core. This design provides greater durability and resistance to wear and tear, making it suitable for use in harsh environments.

The output of a potentiometer transmitter is typically an analog voltage or current signal that corresponds to the position or movement being monitored. This signal can be read and analyzed by electronic devices, such as controllers or computers, to control the operation of machines or provide feedback to operators.

Overall, the structure of a potentiometer transmitter is relatively simple, which contributes to its reliability and ease of use. However, there are also more complex designs available, such as multi-turn potentiometers, which allow for

greater precision and accuracy in measuring position and movement.

Fig 2. Wireless Potentiometer Transmitter

Explore more: Are you looking for a potentiometer transmitter outputting current signal? Don’t hesitate to click here!

Potentiometer Transmitter Types

Linear Potentiometer Transmitter

A linear potentiometer transmitter is a type of potentiometer with a linear resistance track. The working principle of a linear potentiometer transmitter is based on the change in resistance that occurs when a slider or wiper moves along the length of the resistive track. As the wiper moves, it creates a variable resistance that can be used to measure linear displacement or position. Linear potentiometer transmitters are commonly used in applications such as automotive and aerospace industries, robotics, and industrial automation.

Rotary Potentiometer Transmitter

A rotary potentiometer transmitter is a type of potentiometer with a circular resistance track. The working principle of a rotary potentiometer transmitter is based on the change in resistance that occurs when a wiper rotates around the circular resistive track. The wiper creates a variable resistance that can be used to measure rotational displacement or position. Rotary potentiometer transmitters are commonly used in applications such as audio equipment, motor control systems, and industrial automation.

Fig 4. The rotary potentiometer transmitter

Multi-Turn Potentiometer Transmitter

A multi-turn potentiometer transmitter is a type of potentiometer that can make multiple complete rotations or linear movements. The working principle of a multi-turn potentiometer transmitter is similar to that of a single-turn potentiometer transmitter, except that it can make multiple turns or movements. This allows for more precise measurements of position or displacement. Multi-turn potentiometer transmitters are commonly used in applications such as robotics, industrial automation, and precision positioning systems.

Fig 5. Multiturn-Hybrid-Potentiometer AL14

Single-Turn Potentiometer Transmitter

A single-turn potentiometer transmitter is a type of potentiometer that can make only one complete turn or linear movement. The working principle of a single-turn potentiometer transmitter is based on the change in resistance that occurs when a wiper moves along the resistive track. Single-turn potentiometer transmitters are commonly used in applications such as audio equipment, motor control systems, and industrial automation.

Fig 6. Single-Turn Potentiometer Transmitter

Precision Potentiometer Transmitter

A precision potentiometer transmitter is a type of potentiometer that is designed for applications that require high precision and accuracy in a position measurement. The working principle of a precision potentiometer transmitter is similar to that of a standard potentiometer transmitter but with a higher level of accuracy and precision. Precision potentiometer transmitters are commonly used in applications such as aerospace and defense industries, robotics, and scientific research.

Digital Potentiometer Transmitter

A digital potentiometer transmitter is a type of potentiometer that uses digital signals to communicate position information. The working principle of a digital potentiometer transmitter is based on the conversion of analog position information into digital signals that can be transmitted and received by digital devices. Digital potentiometer transmitters are commonly used in applications such as audio equipment, motor control systems, and industrial automation.

Fig 7. Digital Potentiometer Controller

Contactless Potentiometer Transmitter

A contactless potentiometer transmitter is a type of potentiometer that uses non-contact sensing technology, such as magnetic or capacitive sensing, to measure position or displacement without any physical contact between the sensor and the object being measured. The working principle of a contactless potentiometer transmitter is based on the detection of changes in a magnetic or electric field, which are caused by the movement of an object in the vicinity of the sensor. Contactless potentiometer transmitters are commonly used in applications such as automotive and aerospace industries, robotics, and industrial automation where physical contact with the sensor is not possible or desirable.

Fig 8. Contactless Potentiometer Transmitter

Here is a table comparing the different types of potentiometer transmitters:

Table 2. Types comparison

| Type | Working Principle | Applications | Advantages | Disadvantages |

| Linear Potentiometer | Measures linear displacement or position | Automotive, aerospace, robotics, industrial automation | Simple construction, low cost, easy to use | Limited range of motion, not suitable for rotational motion |

| Rotary Potentiometer | Measures rotational displacement or position | Audio equipment, motor control, industrial automation | Can measure rotation, simple construction, low-cost | Limited range of motion, not suitable for linear motion |

| Multi-Turn Potentiometer | Can make multiple complete rotations or linear movements | Robotics, industrial automation, precision positioning | High precision, wide range of motion, suitable for automation | More complex than single-turn potentiometers, higher cost |

| Single-Turn Potentiometer | Can make only one complete turn or linear movement | Audio equipment, motor control, industrial automation | Simple construction, low cost | Limited range of motion, not suitable for multi-turn applications |

| Precision Potentiometer | Designed for high precision and accuracy in position measurement | Aerospace and defense industries, robotics, scientific research | Very high precision and accuracy | More expensive than standard potentiometers, may be more complex |

| Digital Potentiometer | Uses digital signals to communicate position information | Audio equipment, motor control, industrial automation | Digital interface for communication, ease of integration | May be more complex and expensive than analog potentiometers |

| Contactless Potentiometer | Uses non-contact sensing technology to measure position or displacement | Automotive, aerospace, robotics, industrial automation | No physical contact with sensor, suitable for harsh environments | May be more expensive than contact potentiometers, less common |

It's important to note that each type of potentiometer transmitter has its own advantages and disadvantages, and the choice of which type to use will depend on the specific requirements of the application.

Potentiometer Transmitter Applications

Potentiometer transmitters have a wide range of applications across various industries. Some of the common applications of potentiometer transmitters include:

1.Audio equipment

Potentiometer transmitters are used in audio equipment such as volume controls, tone controls, and equalizers.

2.Motor control

Potentiometer transmitters are used in motor control systems to adjust the speed and direction of motors.

3.Robotics

Potentiometer transmitters are used in robotics for the precise positioning of robotic arms and joints.

4.Industrial automation

Potentiometer transmitters are used in various industrial automation applications such as material handling, assembly line automation, and process control.

5.Aerospace and defense

Potentiometer transmitters are used in aerospace and defense industries for precision measurement and control of various systems.

6.Automotive

Potentiometer transmitters are used in automotive applications such as throttle position sensors, steering angle sensors, and suspension position sensors.

7.Scientific research

Potentiometer transmitters are used in scientific research for precise measurement and control of various systems.

8.Medical equipment

Potentiometer transmitters are used in medical equipment such as surgical instruments and patient monitoring systems.

9.Consumer electronics

Potentiometer transmitters are used in consumer electronics such as remote controls and gaming controllers.

What type of output does a Potentiometer Transmitter make?

The output of a potentiometer transmitter is an analog signal, which represents the position or displacement of the potentiometer's wiper. The analog signal can take various forms, depending on the type of potentiometer transmitter.

In a linear potentiometer transmitter, the output signal is a linear voltage or current that varies proportionally with the position of the wiper along the resistor element.

In a rotary potentiometer transmitter, the output signal can be a voltage, current, or resistance that varies proportionally with the angle of rotation of the potentiometer shaft.

In some cases, potentiometer transmitters can also be designed to provide a digital output signal, which can be useful in applications that require high-resolution or digital processing of the position data.

Overall, the output of a potentiometer transmitter is an analog signal that represents the position or displacement of the potentiometer's wiper.

Installation and maintenance

How to use a Potentiometer Transmitter?

A potentiometer transmitter can be used in various ways, depending on the specific application and system requirements. Here are some common ways a potentiometer transmitter can be used:

1.Position sensing

A potentiometer transmitter can be used to sense the position of a linear or rotary component in a system. For example, in a robotic arm, a potentiometer transmitter can be used to sense the position of each joint, allowing the arm to move precisely and accurately.

2.Position control

A potentiometer transmitter can be used to control the position of a component in a system. For example, in a motor control system, a potentiometer transmitter can be used to adjust the speed and direction of the motor by controlling the position of the control knob.

3.Displacement sensing

A potentiometer transmitter can be used to sense the displacement of a component in a system. For example, in a suspension system, a potentiometer transmitter can be used to sense the displacement of the suspension arm, allowing the system to adjust the suspension accordingly.

4.Displacement control

A potentiometer transmitter can be used to control the displacement of a component in a system. For example, in a material handling system, a potentiometer transmitter can be used to adjust the position of a conveyor belt, allowing the system to move materials precisely and accurately.

Potentiometer Transmitter Installation

The installation process for a potentiometer transmitter can vary depending on the specific application and type of potentiometer used. Here are some general guidelines for installing a potentiometer transmitter:

1.Mounting

The potentiometer transmitter should be securely mounted to prevent movement or vibration that could affect its accuracy. The mounting method will depend on the specific application and the type of potentiometer used.

2.Wiring

The potentiometer transmitter will have two or three wires, depending on whether it is a two-wire or three-wire device. The wiring should be connected to the appropriate terminals according to the manufacturer's instructions. The wiring should be protected from environmental factors such as moisture, heat, and vibration.

3.Calibration

Once the potentiometer transmitter is installed, it should be calibrated to ensure accurate measurement and output. Calibration may involve adjusting the zero and span values or other parameters to match the desired range of operation.

4.Testing

After installation and calibration, the potentiometer transmitter should be tested to verify its accuracy and performance. This may involve running the system through its range of motion or displacement while monitoring the output signal.

Overall, the installation process for a potentiometer transmitter will depend on the specific application and type of potentiometer used. It is important to follow the manufacturer's instructions and guidelines to ensure proper installation, calibration, and performance of the device.

How to calibrate the Potentiometer Transmitter?

Calibrating a potentiometer transmitter involves adjusting its output signal to match the actual position or displacement of the system being monitored. Here are some general steps for calibrating a potentiometer transmitter:

1.Verify the zero position

Ensure that the system is at its zero position or fully retracted position. This is the starting point for the calibration process.

2.Adjust the zero offset

Use a multimeter or other measuring device to measure the output signal of the potentiometer transmitter. Adjust the zero offset trimmer or potentiometer on the transmitter until the output signal matches the desired zero position.

3.Verify the full-scale position

Move the system to its maximum position or fully extended position. This is the ending point for the calibration process.

Adjust the span

Use the measuring device to measure the output signal of the potentiometer transmitter at the full-scale position. Adjust the span trimmer or potentiometer on the transmitter until the output signal matches the desired full-scale position.

Test the calibration

Move the system back and forth between its zero and full-scale positions to verify that the potentiometer transmitter output signal accurately reflects the position or displacement of the system.

Record the calibration values

Once the potentiometer transmitter is calibrated, record the zero offset and span values for future reference.

Overall, the calibration process for a potentiometer transmitter involves adjusting the zero offset and span to match the desired zero and full-scale positions of the system being monitored. It is important to use a measuring device to ensure accurate calibration and to test the calibration to verify its accuracy.

Is a Potentiometer Transmitter an accurate device?

Potentiometer transmitters can be accurate devices when properly installed, calibrated, and maintained. However, their accuracy can be affected by various factors such as temperature changes, vibration, and wear and tear over time.

The accuracy of a potentiometer transmitter depends on several factors, including the quality of the potentiometer used, the design of the transmitter circuitry, and the calibration process. High-quality potentiometers and well-designed transmitter circuits can result in more accurate measurements.

It is also important to properly install and maintain the potentiometer transmitter to ensure accurate readings over time. This may include regular cleaning and inspection of the potentiometer and wiring, as well as recalibration if necessary.

Potentiometer Transmitter Advantages and disadvantages

Advantages of Potentiometer Transmitter

1.Low cost

Potentiometer transmitters are relatively inexpensive compared to other types of position sensors.

2.Simple design

Potentiometer transmitters have a simple design, consisting of a potentiometer and some signal conditioning circuitry, which makes them easy to install and maintain.

3.High resolution

Potentiometer transmitters can provide high-resolution measurements of position or displacement, making them suitable for applications that require high accuracy.

4.Wide range of applications

Potentiometer transmitters can be used in a wide range of applications, including industrial automation, robotics, and aerospace.

5.Easy to integrate

Potentiometer transmitters can be easily integrated into existing control systems and measurement systems.

Disadvantages of Potentiometer Transmitter:

1.Limited lifespan

Potentiometer transmitters have a limited lifespan due to the mechanical wear and tear of the potentiometer.

2.Low reliability

Potentiometer transmitters can be less reliable than other types of position sensors, especially in harsh environments or applications with high vibration or shock.

3.Limited measurement range

Potentiometer transmitters have a limited measurement range, typically less than 360 degrees, which can be a limitation in some applications.

4.Susceptible to temperature changes

Potentiometer transmitters can be affected by temperature changes, which can result in measurement errors or drift.

5.Requires regular calibration

Potentiometer transmitters require regular calibration to maintain accurate measurements over time.

Overall, potentiometer transmitters can be a cost-effective and reliable option for measuring position or displacement in a wide range of applications, but they do have some limitations and require regular maintenance and calibration to ensure accurate measurements.

How to choose the right Potentiometer Transmitter?

Choosing the right potentiometer transmitter for a particular application requires considering several factors:

1.Measurement range

Determine the range of motion that needs to be measured and choose a potentiometer transmitter that can accurately measure within that range.

2.Resolution

Determine the required level of precision needed for the measurement and choose a potentiometer transmitter with sufficient resolution to meet those requirements.

3.Output signal

Consider the type of output signal needed for the application, such as voltage or current, and choose a potentiometer transmitter with the appropriate output signal.

4.Operating environment

Consider the operating environment, including factors such as temperature, humidity, vibration, and shock, and choose a potentiometer transmitter that can withstand those conditions.

5.Mounting requirements

Consider the mounting requirements for the potentiometer transmitter and ensure that it can be mounted in the desired location and orientation.

6.Cost

Consider the budget for the application and choose a potentiometer transmitter that provides the required performance at a reasonable cost.

7.Accuracy

Consider the required accuracy for the application and choose a potentiometer transmitter that can provide accurate measurements within the desired tolerance.

By considering these factors, one can choose the right potentiometer transmitter that provides accurate and reliable measurements for the specific application.

The top brands of Potentiometer transmitters

There are several top brands in the market that manufacture potentiometer transmitters. Some of the top brands are:

1.Honeywell

Honeywell is a well-known brand in the field of measurement and control, and they offer a range of potentiometer transmitters for industrial applications. Their potentiometer transmitters are known for their accuracy, reliability, and durability.

2.Datexel

Datexel is a leading manufacturer of electronic components and they offer a range of precision potentiometers and potentiometer-based position sensors for various applications. Their potentiometer transmitters are known for their high accuracy and reliability.

3.Bourns

Bourns is another leading manufacturer of electronic components and they offer a range of potentiometer transmitters for various applications. Their potentiometer transmitters are known for their high accuracy, durability, and cost-effectiveness.

4.Novotechnik

Novotechnik is a global supplier of linear and angular position sensors, and they offer a range of potentiometer transmitters for industrial applications. Their potentiometer transmitters are known for their high accuracy, reliability, and durability.

5.TT Electronics

TT Electronics is a global provider of electronic components and they offer a range of potentiometer transmitters for various applications. Their potentiometer transmitters are known for their high accuracy, durability, and cost-effectiveness.

These top brands have a strong reputation for producing high-quality and reliable potentiometer transmitters that are used in various applications across industries.

Conclusion

A potentiometer transmitter is a type of electrical sensor that is commonly used to measure the position or movement of mechanical components. It is essentially a variable resistor that is designed to respond to changes in position or movement and convert these changes into electrical signals that can be read and analyzed by electronic devices.

Potentiometer transmitters are widely used in a variety of industrial and commercial applications, including robotics, automation, and control systems. They are particularly useful in situations where precise control of position or movement is required, such as in robotic arms, CNC machines, and other types of automated equipment.

The basic design of a potentiometer transmitter consists of a resistive element, which is typically made of a conductive material such as carbon or metal, and a sliding contact or wiper that moves along the length of the resistive element. The position of the wiper along the resistive element determines the resistance of the potentiometer, and this resistance can be measured and used to determine the position or movement of the component being monitored.

One of the main advantages of potentiometer transmitters is their simplicity and reliability. They are relatively inexpensive to manufacture and require very little maintenance, making them a popular choice for a wide range of applications. Additionally, potentiometer transmitters can be very accurate, with resolution as high as 0.1% of full scale.

However, there are also some limitations to using potentiometer transmitters. One of the main issues is that they can be susceptible to wear and tear over time, particularly if they are exposed to harsh environmental conditions such as dust, dirt, or moisture. Additionally, the sliding contact or wiper can sometimes become stuck or jammed, which can lead to inaccurate readings or failure of the potentiometer.

To overcome these limitations, there are several different types of potentiometer transmitters available, each with its unique features and benefits. One example is the wire-wound potentiometer, which is designed with a spiral-wound resistive element that provides greater durability and resistance to wear and tear. Another option is the conductive plastic potentiometer, which uses a conductive polymer material to provide high precision and accuracy, even in harsh environments.

Overall, potentiometer transmitters are a reliable and effective solution for measuring position and movement in a wide range of applications. While there are some limitations to their use, these can be overcome with careful design and selection of the appropriate type of potentiometer for the specific application. As technology continues to evolve, we will likely see even more advanced and sophisticated potentiometer transmitters being developed in the future.

To recap

1.What is a potentiometer transmitter?

A potentiometer transmitter is a device that measures the position or displacement of a moving object and converts it into an electrical signal.

2.What are the applications of a potentiometer transmitter?

Potentiometer transmitters are used in various applications such as industrial machinery, robotics, medical equipment, aerospace, and automotive industries.

3.What is the working principle of a potentiometer transmitter?

The working principle of a potentiometer transmitter is based on the change in resistance of a potentiometer when it is moved. This change in resistance is then converted into an electrical signal.

4.What are the types of potentiometer transmitters?

There are several types of potentiometer transmitters, including linear potentiometers, rotary potentiometers, and string potentiometers.

5.What are the advantages of using a potentiometer transmitter?

Some advantages of using a potentiometer transmitter include high accuracy, reliability, and cost-effectiveness.

6.What are the disadvantages of using a potentiometer transmitter?

Some disadvantages of using a potentiometer transmitter include sensitivity to temperature changes, limited resolution, and potential wear and tear over time.

7.Can potentiometer transmitters be used in harsh environments?

Yes, there are potentiometer transmitters designed to be used in harsh environments, such as those with high temperatures, humidity, and vibration.

8.Can potentiometer transmitters be used for precise measurements?

Yes, potentiometer transmitters can provide precise measurements, especially when they are calibrated and maintained properly.

9.What is the maximum resolution of a potentiometer transmitter?

The maximum resolution of a potentiometer transmitter depends on several factors, including the type of potentiometer, the range of motion, and the sensitivity of the output signal.

10.Can potentiometer transmitters be interfaced with other devices?

Yes, potentiometer transmitters can be interfaced with other devices, such as microcontrollers, PLCs, and data acquisition systems.

11.How are potentiometer transmitters installed?

Potentiometer transmitters can be installed in various ways, including mounting them directly on the moving object or using brackets and supports.

12.How are potentiometer transmitters calibrated?

Potentiometer transmitters can be calibrated by adjusting the zero and span settings to ensure that they provide accurate and reliable measurements.

13.Can potentiometer transmitters be repaired?

Yes, potentiometer transmitters can be repaired in some cases, such as when there is a damaged cable or connector.

14.What is the lifespan of a potentiometer transmitter?

The lifespan of a potentiometer transmitter depends on several factors, including the quality of the device, the operating environment, and the amount of usage.

15.Can potentiometer transmitters be used in safety-critical applications?

Yes, potentiometer transmitters can be used in safety-critical applications, such as in medical devices and aerospace applications, as long as they are properly designed, calibrated, and maintained.

Reference

https://appmeas.co.uk/products/instrumentation/wireless-potentiometer-transmitter-t24-ra/

https://electricalworkbook.com/rotary-potentiometer/

https://store.ncd.io/product/digital-potentiometer-controller-16-channel-256-step/

http://wisco.co.th/main/en/model/pt95

Recent Posts

-

Troubleshooting Common Water Pump Problems: A Step-by-Step Guide

Introduction Water pumps are essential components in a wide range of settings, from homes and farms …1st Apr 2025 -

Boosting Agricultural Efficiency: Centrifugal Water Pumps

1. Introduction Agricultural irrigation is crucial in maintaining consistent crop growth and ensurin …28th Mar 2025 -

The Ultimate Guide to Launching a Robotic Coffee Business

The Ultimate Guide to Launching a Robotic Coffee BusinessTable of ContentSEOFAQ - CatalogSales Advic …28th Mar 2025