Boosting Agricultural Efficiency: Centrifugal Water Pumps

1. Introduction

Agricultural irrigation is crucial in maintaining consistent crop growth and ensuring productivity, particularly in areas with unpredictable rainfall or limited water resources. For many farmers, an efficient irrigation system can mean the difference between a successful harvest and crop failure, especially in regions facing water scarcity challenges. As demand for sustainable water solutions rises, centrifugal water pumps have become an essential component in modern irrigation systems.

Centrifugal water pumps offer a versatile, energy-efficient, and reliable solution to meet irrigation needs across various scales of agriculture. These pumps help distribute water evenly, improving soil moisture levels and crop yield while reducing labor and operational costs. Their adaptability to different types of irrigation, from drip systems to large-scale sprinklers, makes them a preferred choice for farmers aiming to optimize both resource use and productivity.

In this post, we’ll delve into how centrifugal pumps work, explore the types available, and provide guidance on selecting the right pump for your agricultural irrigation needs. Whether you’re a small-scale grower or managing extensive farmland, understanding the capabilities of centrifugal water pumps will help you make informed decisions to boost efficiency and support sustainable agriculture.

2. Overview of Agricultural Irrigation Pumps

Different Types of Irrigation Pumps

In agricultural irrigation, selecting the right pump is critical for maintaining efficient water distribution to crops. The three primary types of pumps used in irrigation are centrifugal pumps, submersible pumps, and self-priming pumps. Each pump type has unique characteristics that suit different water sources and irrigation setups.

- Centrifugal Pumps: These are surface pumps that move water using centrifugal force generated by a rotating impeller. Centrifugal pumps are ideal for applications requiring high flow rates, such as large-scale farms and open field irrigation. They are often used in drip and sprinkler irrigation systems and work best when water sources are at or above ground level.

- Submersible Pumps: Designed to operate fully submerged in water, submersible pumps are particularly useful for drawing water from wells, ponds, or underground sources. These pumps push water from within the source, eliminating the need for priming and making them efficient in deeper water applications, such as deep wells or aquifers.

- Self-Priming Pumps: Self-priming pumps can create their own suction, making them easy to use without manual priming. They’re commonly used when there’s a need for uninterrupted water flow, such as in large irrigation systems, and can handle a range of water qualities, including those with solids or gasses.

Comparison: Centrifugal vs. Submersible Pumps

While centrifugal and submersible pumps are both popular in agricultural irrigation, they differ in application suitability and installation requirements.

- Installation: Centrifugal pumps are placed above ground, drawing water from the source through suction. This design simplifies maintenance and makes centrifugal pumps accessible for repairs. Conversely, submersible pumps operate entirely underwater, which provides efficient water movement with minimal energy loss but makes maintenance more challenging.

- Efficiency: Submersible pumps generally have higher energy efficiency for deeper water sources due to reduced friction and gravity effects. However, centrifugal pumps excel in terms of high flow rates, making them more suitable for extensive irrigation systems covering large fields.

- Application Suitability: For irrigation systems requiring high-pressure and high-flow rates, centrifugal pumps are preferred. Submersible pumps, on the other hand, are better suited for deeper sources like wells, where consistent water extraction is essential.

Advantages of Centrifugal Pumps for Agriculture

Centrifugal pumps stand out as a reliable choice in agriculture due to their several key advantages:

- Energy Efficiency: Centrifugal pumps are designed for high efficiency in high-flow applications. Their ability to deliver large volumes of water with minimal energy loss reduces operating costs, making them a sustainable choice for ongoing irrigation.

- Adaptability: From drip irrigation to pivot sprinklers, centrifugal pumps can be easily integrated with different irrigation setups, providing flexibility for farms of varying sizes and requirements.

- Cost-Effectiveness: The upfront cost of centrifugal pumps is generally lower than that of submersible pumps, especially for surface-level water sources. Combined with their low maintenance needs and high durability, centrifugal pumps offer excellent value over time.

By understanding these pump types and the benefits of centrifugal pumps, farmers can make informed choices to enhance their irrigation systems, optimize water usage, and ultimately support productive, sustainable agriculture.

3. How Centrifugal Water Pumps Work

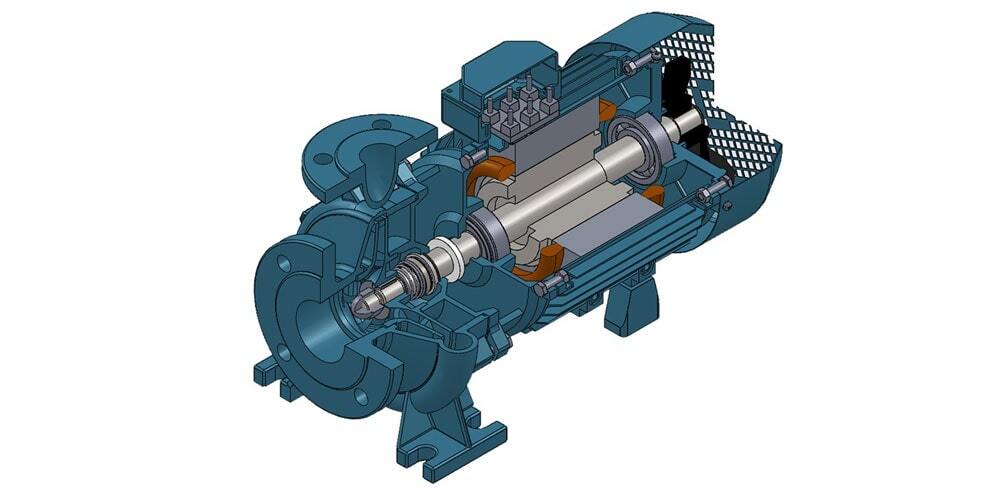

Centrifugal water pumps are engineered to move water through the principle of centrifugal force, making them a highly efficient solution for agricultural irrigation. At the heart of this process is the impeller, a rotating component that creates a powerful outward force, driving water through the pump and out toward the irrigation system. When the impeller spins, it generates kinetic energy, pushing water to the outer edges of the pump chamber and creating pressure that propels the water forward. This mechanism is simple but effective, allowing for high flow rates and reliable operation.

Components of a Centrifugal Pump

- Impeller: The impeller is the driving force behind water movement within a centrifugal pump. As it rotates, it draws water into the pump and then propels it outward through centrifugal force. The impeller’s design—its shape, size, and number of blades—significantly impacts the pump’s flow rate and efficiency. A well-designed impeller maximizes water movement while minimizing energy loss, providing a consistent and reliable water supply essential for effective irrigation.

- Volute and Casing: Surrounding the impeller, the volute and casing work together to stabilize water pressure and direct flow. The volute, a curved section within the casing, gradually reduces water velocity while converting kinetic energy into pressure, allowing the pump to deliver water at a consistent rate. The casing, typically made of durable materials like cast iron, also protects the internal components from external damage and ensures the pump’s longevity, even under tough agricultural conditions.

- Mechanical Seal and Motor: The mechanical seal prevents water from leaking out of the pump, maintaining efficiency and preventing unnecessary wear. Proper sealing is crucial to ensure that water flows effectively through the system without escaping. The motor powers the impeller and, in turn, the entire pump operation. An efficient motor is essential for reducing energy consumption, and modern motors are often designed for high efficiency to save on operating costs. Regular maintenance of the motor and seals can greatly extend the pump’s life and ensure consistent performance.

- Pump Variants: Monoblock Designs: Monoblock centrifugal pumps are a popular choice for their compact design, in which the pump and motor share a single shaft. This close-coupled structure reduces energy loss between the motor and impeller, improving overall efficiency. Monoblock designs are often quieter and easier to install, making them suitable for farms where efficiency and space-saving are priorities.

Now that we know how centrifugal pumps operate, let’s explore the different types of centrifugal pumps and the unique advantages each offers for irrigation.

4. Types of Centrifugal Pumps for Agricultural Irrigation

Understanding the different types of centrifugal pumps helps farmers choose the best option for their specific irrigation needs. Here are some common centrifugal pump types used in agriculture:

- JET Pumps: Known for their ability to lift water from lower depths, JET pumps are fitted with a venturi tube and nozzle, creating a suction effect that draws water from depths of up to 8-9 meters. JET pumps are ideal for shallow wells and garden sprinkler systems where moderate flow and lift are required. Their self-priming ability also makes them convenient for setups where easy startup and operation are essential.

- Multistage Pumps: These pumps consist of multiple impellers stacked within a single casing, allowing for significantly higher pressure output than single-stage pumps. Multistage pumps are commonly used for large-scale farms requiring extensive water distribution or high-pressure applications. Their high efficiency and pressure make them well-suited for long-distance water transportation or large drip and sprinkler systems where consistent pressure is critical.

- End Suction Pumps: End suction pumps are versatile and offer high flow capacities, making them suitable for a variety of agricultural uses. They are easy to install and maintain, with a simple design that supports efficient water flow. Because of their adaptability, end suction pumps are often used in extensive irrigation systems that require consistent water flow over large fields.

- Self-Priming Pumps: These pumps can automatically prime themselves, drawing water into the system without manual priming, making them highly convenient for systems where consistent water flow is crucial. Self-priming pumps are particularly versatile, capable of handling a range of water qualities and performing well in variable conditions. This makes them an excellent choice for farms with diverse irrigation requirements and fluctuating water sources.

Each pump type brings something unique to the table, but what do all centrifugal pumps have in common? Let’s dive into the specific benefits they offer for agriculture.

5. Benefits of Using Centrifugal Pumps in Agriculture

Centrifugal pumps offer several advantages that make them ideal for agricultural irrigation. These benefits not only support better crop health but also improve farm operations by saving time and reducing costs.

- Efficient Water Distribution: Centrifugal pumps provide a consistent and even delivery of water, which is essential for maintaining optimal soil moisture across large agricultural fields. Uniform water distribution is vital for plant growth, ensuring each crop receives the required amount of water to thrive. By using centrifugal pumps, farmers can achieve efficient water coverage, improving crop health and productivity.

- Time and Labor Savings: Centrifugal pumps are easy to automate, reducing the need for manual water distribution and minimizing labor costs. Automation allows farmers to focus on other critical tasks, making farm management more efficient. The pumps’ reliable operation also means less downtime, saving time during crucial irrigation periods.

- Cost Savings and Energy Efficiency: Designed for high efficiency, modern centrifugal pumps consume less energy than other types of irrigation pumps, leading to lower electricity costs over time. The durability and low-maintenance requirements of centrifugal pumps further contribute to their cost-effectiveness, providing a valuable return on investment as they reduce both operational and maintenance expenses.

- Improved Crop Yield and Quality: With consistent water delivery, centrifugal pumps play a direct role in enhancing crop yield and quality. By preventing over- or under-watering, these pumps help maintain optimal growing conditions, leading to healthier plants and better harvests. This efficiency in irrigation directly impacts the productivity and profitability of the farm, as high-quality produce can demand better market prices.

In sum, centrifugal pumps support a balanced, efficient, and cost-effective irrigation process that helps farmers maximize their resources while promoting sustainable crop growth. Their reliability and adaptability make them a key asset for modern agriculture, particularly in areas where water efficiency and operational cost savings are essential.

6. Choosing the Right Centrifugal Pump for Agricultural Needs

Selecting the right centrifugal pump for agricultural irrigation is crucial to ensure efficient water use and consistent crop growth. Farmers must consider various factors, including the water source, irrigation system requirements, maintenance needs, and regional considerations, to find a pump that meets both their immediate and long-term needs.

- Water Source: Understanding the water source is fundamental in choosing the best pump. Centrifugal pumps are ideal for surface-level sources like ponds, rivers, and municipal systems, where suction lift is minimal. For shallow wells (up to 8-9 meters), JET pumps can effectively lift water and provide adequate pressure. If your farm relies on a deep well, consider a multistage pump or an alternative submersible solution, as centrifugal pumps may not be suited for high-lift applications. Knowing your water source depth, volume, and distance from the fields will guide you in selecting a pump with the right capacity and head pressure.

- Irrigation System Requirements: The size and type of irrigation system, along with the specific crop requirements, directly influence pump choice. Large fields with high water demand may benefit from multistage centrifugal pumps, which offer strong pressure and consistent water delivery. For smaller fields or systems with lower flow requirements, an end suction or JET pump may be suitable. Additionally, crops with higher moisture needs, like fruits and vegetables, may require pumps capable of sustaining longer and more frequent irrigation cycles, whereas less water-intensive crops can work with moderate-flow pumps.

- Maintenance and Longevity: For farms looking for long-term solutions, the ease of maintenance and durability of the pump are essential considerations. Pumps with simple designs and durable materials, like monoblock centrifugal pumps, are easy to maintain and have a long lifespan. Regular maintenance helps extend the pump’s life, but choosing a model known for reliability and low maintenance needs will optimize return on investment (ROI) and minimize downtime. Investing in quality pumps with readily available replacement parts also ensures quick repairs if needed.

- Considerations for Dubai and UAE: In hot and arid regions like Dubai and the UAE, water scarcity and high temperatures are pressing concerns. Centrifugal pumps with energy-efficient motors and durable, heat-resistant components are ideal for withstanding these challenging conditions. Pumps that maintain performance under high temperatures and reduce water waste through efficient operation are particularly valuable in these climates. Additionally, using pumps with variable-speed drives can help manage energy costs and optimize water delivery to match the specific needs of arid agricultural environments.

With the right pump in place, proper maintenance becomes essential. Let’s go over how to keep your centrifugal pump in top condition for years to come.

7. Practical Guide to Maintenance and Troubleshooting

Regular maintenance is essential for keeping centrifugal pumps running efficiently and avoiding unexpected breakdowns. Here’s a guide to routine maintenance and troubleshooting tips to ensure long-lasting performance.

- Routine Maintenance Tips:

- Impeller Inspection: Regularly check the impeller for wear, clogging, or damage. A clean, intact impeller maintains optimal flow and pressure, essential for consistent irrigation.

- Seal Checks: Mechanical seals prevent water leakage and preserve pump efficiency. Inspect seals periodically and replace them if there are signs of wear, such as water seepage or reduced pressure.

- Motor Servicing: Keep the motor clean and free of dust to prevent overheating. Lubricate bearings as recommended by the manufacturer to ensure smooth operation and prevent wear.

- Preventive Measures to Extend Pump Life:

- Regular Cleaning: Dirt, sediment, and algae can accumulate in the pump, reducing its efficiency and potentially causing clogging. Cleaning the pump chamber and intake regularly will prevent these issues and keep water flow unrestricted.

- Avoiding Cavitation: Cavitation, or the formation of vapor bubbles due to low pressure, can damage the impeller and reduce pump efficiency. To prevent cavitation, ensure that the pump operates within its specified pressure range and avoid running the pump dry.

- Inspecting and Replacing Worn Parts: Bearings, seals, and other components will wear over time, especially in demanding agricultural conditions. Regularly inspecting these parts and replacing them as needed will prevent more extensive damage and costly repairs.

- Common Troubleshooting Tips:

- Reduced Water Flow: If the pump is not delivering the expected flow rate, check for blockages in the intake, impeller, or discharge pipe. Also, inspect for air leaks in the suction line, which can reduce suction power.

- Overheating: An overheating motor may indicate a lubrication issue, excessive dust buildup, or electrical problems. Clean the motor, ensure proper ventilation, and check that the motor is operating within its rated capacity.

- Unusual Noises: Strange sounds can be a sign of cavitation, bearing failure, or loose components. Identify the source of the noise, tighten loose parts, and replace any faulty components to prevent further damage.

8. Cost Savings and ROI with Centrifugal Pumps

Investing in a high-quality centrifugal pump may have a higher initial cost, but the long-term savings and ROI make it a worthwhile choice for agricultural irrigation. Here’s how centrifugal pumps balance costs with efficiency:

- Initial Investment vs. Long-Term Savings: While premium centrifugal pumps may require a higher upfront cost, they pay off over time through reduced maintenance, lower energy consumption, and longer life spans. High-quality pumps are more resistant to wear, reducing the need for frequent replacements and costly repairs. By choosing durable pumps, farmers save on both operational expenses and maintenance fees.

- Energy Efficiency and Cost-Effectiveness: Modern centrifugal pumps are designed for energy efficiency, which is especially important given rising energy costs. Efficient motors and optimized pump designs allow for substantial energy savings during operation, lowering electricity bills for farmers. Pumps with variable-speed drives can further reduce energy use by adjusting to the farm’s water requirements, enhancing both efficiency and cost savings.

- Comparison with Other Irrigation Solutions: Compared to other irrigation solutions like submersible or positive displacement pumps, centrifugal pumps offer a balance between scalability and maintenance costs. Centrifugal pumps are versatile and can be adapted to various field sizes and irrigation needs, making them suitable for large-scale farming. They also generally have lower maintenance costs, making them a more economical option for extensive irrigation systems that require regular operation.

In conclusion, centrifugal pumps provide significant cost advantages through their efficiency, durability, and adaptability, making them a smart investment for farmers looking to boost productivity while controlling operational expenses. By selecting the right pump and maintaining it well, agricultural operations can benefit from consistent, efficient irrigation for years to come.

As we explore the financial advantages, you may have some lingering questions. Here, we answer the most common questions about centrifugal pumps for agriculture.

9. Frequently Asked Questions (FAQs)

1. How does a centrifugal pump work in irrigation?

Centrifugal pumps work by using centrifugal force to move water. When the pump’s impeller rotates, it draws water into the center and then propels it outward through the volute casing, creating a flow that pushes water through the irrigation system. This design allows for efficient water delivery across large fields, making centrifugal pumps ideal for various agricultural irrigation applications.

2. What is the best water pump for agricultural irrigation?

The best pump depends on specific factors such as field size, water source, and irrigation system. For high-flow and high-pressure needs, multistage centrifugal pumps are often the best choice due to their strong performance in large fields. JET pumps are effective for shallow wells, while self-priming centrifugal pumps offer convenience for continuous water supply without manual priming. End suction pumps are versatile and suitable for a range of irrigation types, making them an excellent choice for many farms.

3. Why are centrifugal pumps preferred for farm irrigation?

Centrifugal pumps are preferred for farm irrigation due to their high efficiency, ease of use, and adaptability. They deliver consistent water flow, which is essential for uniform crop growth. Additionally, centrifugal pumps can be used with various irrigation systems, from drip to pivot, making them versatile tools for diverse agricultural settings. Their relatively low maintenance needs and energy efficiency further make them a cost-effective option.

4. How do I maintain a centrifugal irrigation pump?

Regular maintenance of a centrifugal irrigation pump includes routine inspection of the impeller, seals, and motor. Cleaning the pump’s intake and discharge areas prevents blockages, and checking the mechanical seals ensures water doesn’t leak from the system. Lubricate motor bearings as recommended by the manufacturer, and keep the motor free of dust and debris to prevent overheating. Following these practices will extend the pump’s life and maintain optimal performance.

5. What cost savings can I expect from efficient pumps?

Efficient centrifugal pumps consume less energy, which lowers electricity costs over time. Additionally, high-quality pumps with durable components require less frequent repairs, reducing maintenance expenses. For large-scale irrigation, this translates to significant long-term savings, as efficient pumps minimize water wastage and operate at optimal power, ensuring farmers get the best return on investment.

6. How does pump efficiency affect crop yield?

Efficient pumps provide a reliable and even water distribution, which is critical for maintaining consistent soil moisture. This uniformity helps crops grow evenly, enhancing both yield and quality. By preventing over- or under-watering, an efficient pump creates ideal growing conditions that can improve plant health, increase productivity, and maximize the farm’s overall output.

Now that you’re well-equipped with the essentials of centrifugal pumps, let’s recap the key takeaways and see why they’re a smart choice for agricultural irrigation.

10. Conclusion

Centrifugal pumps have proven to be essential tools in modern agriculture, offering efficient and reliable solutions for farm irrigation. Their simple yet effective design enables consistent water delivery across large fields, supporting uniform crop growth and improved yields. Whether for small-scale farms or extensive agricultural operations, centrifugal pumps are adaptable to various irrigation systems, making them versatile assets in farm management.

The benefits of centrifugal pumps—such as ease of use, low maintenance requirements, and energy efficiency—underscore their value in agricultural settings. They not only help optimize water use but also reduce operational costs, providing long-term savings and supporting sustainable farming practices. This is especially important in water-scarce regions like Dubai and the UAE, where efficient water management is crucial for maintaining agricultural productivity.

For farmers looking to boost efficiency and make a sound investment, centrifugal pumps offer a dependable solution. By choosing the right pump and maintaining it properly, agricultural operations can achieve optimal irrigation performance, ensuring healthier crops and contributing to a sustainable future in farming.

Resources:

https://www.streampumps.com/pump-solutions/agricultural-irrigation-pump-solutions-240814.html

https://www.streampumps.com/pump-solutions/irrigation-pump-solution-240814.html

https://www.streampumps.com/pump-introductions/Self-Priming-Pumps-news.html

https://www.streampumps.com/pump-introductions/news-2023-5-17.html

Recent Posts

-

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025 -

Single-Stage, Multi-Stage, and Variable Speed Booster Pumps: Which One is Right for You?

1. Introduction Is your shower lacking the invigorating pressure you crave? Do your faucets tri …13th Apr 2025