Defending Against Risks: Pressure Sensor Safety Strategies You Should Consider Part 1

Navigating safety considerations around pressure sensors in hazardous environments involves a complex interplay of standards, regulations, and practical applications. Ensuring safety involves understanding the risks associated with these sensors, implementing proper installation, maintenance, and protective measures, and staying compliant with industry-specific standards. It's a multifaceted landscape that necessitates a comprehensive approach to mitigate potential hazards and create a secure working environment. If you have more specific inquiries or need detailed information, don't hesitate to ask!

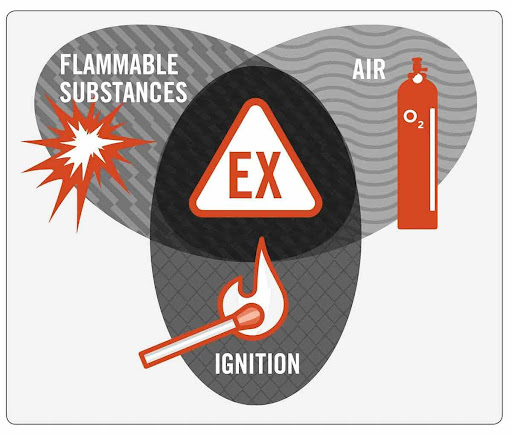

Fig 1. Safety of pressure sensors

Why should safety tips be observed while using a pressure sensor?

Observing safety tips while using pressure sensors is crucial to prevent accidents, and equipment damage, and ensure accurate readings. Firstly, proper handling and installation are essential. Users should carefully follow manufacturer guidelines for installation, ensuring the sensor is compatible with the intended system and placed correctly. Mishandling during installation can lead to inaccuracies, malfunctions, or even physical damage to the sensor, posing safety risks and potential financial losses.

Secondly, calibration and maintenance are key safety measures. Regular calibration ensures the accuracy of pressure readings, preventing errors that could lead to hazardous situations in industries like manufacturing or healthcare. Additionally, routine maintenance helps identify any potential issues early on, preventing sudden failures or inaccuracies. It's crucial to adhere to recommended maintenance schedules to guarantee the sensor's reliability and safety, ultimately safeguarding both personnel and equipment within various operational environments.

Why should safety tips be observed while using pressure sensors?

Observing safety tips while using pressure sensors is essential for several reasons. Firstly, it ensures the well-being of personnel and the protection of equipment. Mishandling or improper installation of pressure sensors can lead to malfunctions, inaccuracies, or even physical damage, potentially causing accidents or injury. Following safety, protocols minimizes these risks and maintains a secure working environment.

Secondly, adhering to safety guidelines ensures the accuracy and reliability of pressure measurements. In industries such as manufacturing, healthcare, or aerospace, precise pressure readings are critical for operations. Any error due to mishandling or neglecting safety measures could result in faulty data, leading to suboptimal performance or even catastrophic consequences in critical systems. By observing safety tips, users maintain the integrity of pressure sensors, ensuring dependable and trustworthy measurements, which are fundamental for safe and efficient operations.

What happens if don't follow the safety tips?

Not following safety tips while using pressure sensors can lead to various adverse outcomes. Firstly, there's an increased risk of accidents or injury to personnel. Mishandling pressure sensors during installation, calibration, or maintenance could result in equipment failure or unexpected pressure releases, potentially causing harm to those nearby.

Secondly, disregarding safety guidelines can compromise the accuracy and reliability of pressure readings. This could lead to incorrect measurements, impacting critical processes in industries such as manufacturing, healthcare, or automotive. Inaccurate pressure data might result in faulty decision-making, equipment malfunction, or system failures, leading to financial losses, production delays, or even more severe consequences in certain scenarios, like compromised safety in high-pressure environments or critical systems.

Overall, not following safety tips while using pressure sensors not only poses risks to personnel safety but also threatens the efficiency and reliability of operations dependent on accurate pressure measurements.

What are the consequences of ignoring safety tips?

Ignoring safety tips while using pressure sensors can lead to several consequences, ranging from immediate risks to long-term impacts.

Immediate dangers include the potential for accidents or injuries. Mishandling or improper installation could result in equipment malfunction or sudden pressure releases, causing harm to individuals nearby. This immediate risk poses a direct threat to the safety of personnel working with or around the sensors.

In the mid-to-long term, ignoring safety tips can compromise the reliability and accuracy of pressure readings. This might lead to incorrect measurements, impacting critical processes and decision-making in various industries. For instance, inaccurate pressure data in manufacturing could result in defective products or compromised quality control. In healthcare, incorrect readings might affect patient monitoring or treatment. Furthermore, neglecting safety tips could lead to equipment damage or premature wear and tear, resulting in increased maintenance costs, downtime, and potential system failures.

Ultimately, the consequences of disregarding safety tips not only jeopardize the immediate safety of individuals but also threaten the efficiency, productivity, and reliability of processes reliant on accurate pressure measurements.

The consequences of ignoring safety tips

Sure, here are the consequences of ignoring safety tips when using pressure sensors:

Importance of prioritizing safety during installation and calibration of pressure transmitters

Prioritizing safety during the installation and calibration of pressure transmitters is crucial for several reasons:

What safety tips should be observed while using pressure sensors?

Here are some key safety tips to observe while using pressure sensors:

Fig 2. Oil pressure safety switches

What are the safety rules in industry regulations, standards, and best practices?

Safety rules in industry regulations, standards, and best practices vary based on the sector and specific applications. However, there are overarching principles and common guidelines that often apply:

Industry regulations, standards, and best practices for pressure sensors

Regulations, standards, and best practices for pressure sensors are often governed by industry-specific organizations and guidelines. Here are some commonly referenced standards and practices:

- Proper Installation: Following manufacturer guidelines and industry standards for correct sensor installation to ensure accurate readings and prevent damage.

- Calibration and Maintenance: Regular calibration according to recommended intervals and maintenance checks to ensure accurate and reliable sensor performance.

- Environmental Considerations: Choosing sensors rated for the intended environmental conditions (temperature, pressure, and media) and implementing necessary protections.

- Safety Protocols: Implementing safety measures to protect personnel and equipment, especially in high-pressure or hazardous environments.

Adherence to these regulations, standards, and best practices helps ensure the accurate functioning, safety, and reliability of pressure sensors across various industries.

How can hazardous environments where pressure transmitters may be installed?

Identifying hazardous environments where pressure transmitters may be installed involves assessing various factors related to the surroundings and the substances or conditions present. Here are some steps to identify such environments:

How can Understand Industry Classifications of hazardous areas for pressure sensors?

Understanding industry classifications of hazardous areas for pressure sensors involves familiarizing yourself with the systems and standards used to define these areas. Here's how you can do it:

What are the possible dangers in hazardous areas for pressure sensors?

Hazardous areas present various dangers for pressure sensors, mainly due to the presence of potentially volatile or hazardous substances and environmental conditions. Some possible dangers include

How to deal with these dangers caused by hazardous areas?

Dealing with the dangers caused by hazardous areas involves a multi-faceted approach that prioritizes safety, compliance, and proper equipment handling. Here's a breakdown of steps to address these dangers:

What are the important factors in choosing the proper pressure sensor for hazardous environments?

Selecting the right pressure sensor for hazardous environments involves considering several crucial factors to ensure safety, compliance, and optimal performance. Here are the key considerations:

Fig 3. Safety DIN connector for pressure sensor

Which types of pressure sensors are suitable for hazardous environments?

Several types of pressure sensors are designed and certified for use in hazardous environments, meeting stringent safety requirements and standards. The suitability of a pressure sensor for a hazardous area depends on the specific classification and conditions of that environment. Here are some types commonly used in hazardous areas:

Are the pressure sensors of different types suitable for hazardous environments?

Here are different types of pressure sensors commonly suitable for hazardous environments:

Ex-certification and its significance in hazardous environments

The "Ex certification" refers to a certification granted to equipment designed for use in potentially explosive atmospheres, indicating compliance with specific safety standards. The "Ex" designation comes from the Latin word "Exempli" (meaning example) and is commonly associated with hazardous area equipment certifications.

The significance of Ex certification in hazardous environments lies in several key aspects:

- Safety Assurance: Ex-certified equipment undergoes rigorous testing and assessment to ensure it meets the safety standards required for use in potentially explosive atmospheres. This certification confirms that the equipment is designed to minimize the risk of ignition and prevent accidents in these sensitive environments.

- Compliance with Standards: Ex-certification demonstrates compliance with industry-specific standards such as ATEX (Europe), IECEx (international), NEC (National Electrical Code in the US), or other regional regulations. It ensures that the equipment meets the criteria for safe operation in hazardous locations based on their classification (e.g., Zone, Class/Division).

- Risk Mitigation: In hazardous environments where flammable gases, vapors, combustible dust, or other hazardous substances are present, Ex-certified equipment helps mitigate the risk of ignition, explosions, or fires. It provides a level of confidence that the equipment can operate safely without posing a threat to the environment or personnel.

- Legal Compliance: Many jurisdictions and industries mandate the use of Ex-certified equipment in hazardous areas to comply with safety regulations and standards. Failure to use certified equipment in such environments can result in legal consequences or regulatory non-compliance.

- Reliability and Performance: Ex-certified equipment undergoes stringent testing to ensure its reliability and performance in challenging conditions. It is designed to withstand the environmental factors present in hazardous areas without compromising accuracy or functionality.

In summary, Ex certification is crucial for equipment intended for use in hazardous environments as it signifies compliance with safety standards, ensures safety in potentially explosive atmospheres, and provides confidence in the reliability and performance of the equipment under challenging conditions.

IECEx certification for international markets

IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is a globally recognized certification system for equipment intended for use in potentially explosive atmospheres. It ensures conformity with international standards and facilitates the international acceptance of products used in hazardous locations.

Here's an overview of IECEx certification:

- Global Recognition: IECEx is recognized internationally and harmonizes standards related to explosive atmospheres across different countries, streamlining the acceptance of certified equipment in various markets worldwide.

- Compliance with IEC Standards: IECEx certification is based on compliance with relevant International Electrotechnical Commission (IEC) standards related to hazardous area equipment, such as the IEC 60079 series.

- Harmonization of Standards: It aims to harmonize the standards for equipment used in explosive atmospheres, providing a consistent framework for manufacturers, users, and regulatory bodies globally.

- Certification Process: Manufacturers seeking IECEx certification undergo a rigorous assessment process by an accredited certification body. This process involves testing, inspection, and assessment of the equipment to ensure compliance with IEC standards and requirements.

- Marking and Documentation: IECEx-certified equipment bears the IECEx mark, indicating its compliance with international standards for use in hazardous locations. Manufacturers provide comprehensive documentation, including test reports and technical specifications, to support the certification.

- Benefits of IECEx: The certification enhances safety by ensuring that equipment is designed, manufactured, and tested to prevent ignition sources in potentially explosive atmospheres. It facilitates market access by providing a globally recognized certification, easing trade barriers for manufacturers seeking to export their products.

- Applications: IECEx certification is crucial for various industries, including oil and gas, mining, chemical processing, pharmaceuticals, and manufacturing, where explosive atmospheres may exist.

IECEx certification streamlines the process for manufacturers to demonstrate the conformity of their equipment to international standards, enabling safer and more efficient operations in hazardous environments across global markets.

Explanation of ATEX (Atmosphères Explosibles) certification for Europe

ATEX (Atmosphères Explosibles) is a certification indicating compliance with European Union directives concerning equipment and protective systems intended for use in potentially explosive atmospheres. It encompasses equipment designed to be used in environments with a risk of explosion due to the presence of flammable gases, vapors, mists, or combustible dust.

ATEX certification comprises two directives:

- ATEX Directive 2014/34/EU (Equipment Directive): This directive focuses on equipment and protective systems intended for use in potentially explosive atmospheres. It outlines the essential health and safety requirements for such equipment and systems.

- ATEX Directive 1999/92/EC (Worker Protection Directive): This directive addresses the health and safety protection of workers in potentially explosive atmospheres. It provides guidelines for employers to assess and manage the risks related to explosive atmospheres in the workplace.

Key components and aspects of ATEX certification include:

- Equipment Categories: ATEX categorizes equipment into groups, categories, and zones based on the type of hazardous substance present and the level of risk. Equipment is certified for specific categories and zones, indicating its suitability for use in those environments.

- Manufacturer Responsibilities: Manufacturers must ensure that their equipment meets the essential health and safety requirements outlined in the directives. They conduct risk assessments, design equipment to prevent ignition sources, and provide documentation and instructions for safe use.

- Certification and Marking: ATEX-certified equipment carries a specific marking indicating compliance. The marking includes the CE mark along with an Ex symbol and a code representing the certification body.

- Compliance Assessment: Before placing equipment on the market, manufacturers must have their products assessed by a notified body to ensure conformity with ATEX directives.

ATEX certification is essential for equipment used in industries such as oil and gas, chemical manufacturing, mining, pharmaceuticals, and others where potentially explosive atmospheres may exist. It ensures that equipment is designed, manufactured, and used in a manner that minimizes the risk of ignition, thereby enhancing safety in these hazardous environments.

Fig 4. ATEX symbols

ATEX certification for Pressure Sensors

ATEX certification for pressure transmitters is crucial for their safe and reliable use in potentially explosive atmospheres. Pressure transmitters are commonly employed in industries such as oil and gas, chemical processing, pharmaceuticals, and others where there's a risk of explosive atmospheres due to the presence of flammable gases, vapors, mists, or combustible dust.

Here's a detailed discussion on ATEX certification specific to pressure transmitters:

- ATEX Equipment Directive (2014/34/EU): This directive outlines the requirements for equipment intended for use in explosive atmospheres. Pressure transmitters fall under this directive if they are used in such hazardous areas.

- Classification of Hazardous Zones: ATEX categorizes hazardous areas into zones based on the likelihood and duration of the presence of an explosive atmosphere. For example:

- Zone 0: Where an explosive atmosphere is present continuously or for long periods.

- Zone 1: Where an explosive atmosphere is likely to occur under normal operating conditions.

- Zone 2: Where an explosive atmosphere is not likely to occur or, if it does, it will be for short periods.

- Certification Process: Manufacturers of pressure transmitters seeking ATEX certification must comply with the essential health and safety requirements outlined in the directive. They undergo an assessment by notified bodies to ensure their products meet these requirements and are suitable for the intended hazardous zones.

- Design and Construction Requirements: Pressure transmitters for ATEX certification must be designed to prevent ignition sources that could trigger explosions in potentially explosive atmospheres. They must incorporate features such as intrinsically safe circuitry, explosion-proof enclosures, or protective measures to ensure safety.

- ATEX Marking: ATEX-certified pressure transmitters bear the CE mark along with an Ex symbol and a specific code indicating the conformity assessment body. This marking confirms their compliance with ATEX requirements and their suitability for use in the designated hazardous zones.

- Documentation and Technical Files: Manufacturers provide comprehensive documentation, technical specifications, and test reports to support ATEX certification. This includes information on the equipment's design, intended use, and safety measures implemented to prevent ignition sources.

- Ongoing Compliance: ATEX certification is not a one-time process. Manufacturers must ensure ongoing compliance by maintaining the quality and safety standards of their pressure transmitters through regular assessments and adherence to ATEX directives.

ATEX-certified pressure transmitters play a critical role in ensuring safe operations in hazardous environments by providing accurate and reliable pressure measurements without posing risks of ignition or accidents due to explosive atmospheres. The certification process ensures that these instruments meet stringent safety standards and are suitable for their intended use in specific hazardous zones.

What are the ATEX directives?

ATEX directives refer to two key directives established by the European Union to regulate equipment and protective systems intended for use in potentially explosive atmospheres. These directives aim to ensure the safety of equipment used in environments with a risk of explosion due to the presence of flammable gases, vapors, mists, or combustible clouds of dust.

The two main ATEX directives are

- It specifies the requirements for the design, manufacturing, and use of equipment to prevent the occurrence of explosions in hazardous areas.

- Manufacturers must ensure that their products meet these essential health and safety requirements and undergo conformity assessment procedures before placing them on the market.

- It requires employers to conduct risk assessments, classify hazardous areas, implement measures to prevent explosions, and protect workers' health and safety in these areas.

- Employers must provide appropriate training, information, and protective measures to ensure the safety of workers operating in potentially explosive atmospheres.

What are the ATEX equipment groups and categories?

ATEX equipment groups categorize devices based on the type of hazardous substance they are designed to handle. These groups help in identifying the specific risks associated with different types of potentially explosive atmospheres and guide the selection of appropriate equipment for those environments. There are two main ATEX equipment groups:

- Category 1: Designed for use in areas with the highest risk of explosive atmospheres, such as Zone 0.

- Category 2: Suitable for use in areas with a significant risk of explosive atmospheres, such as Zone 1.

- Category 3: Intended for use in areas with a lower risk of explosive atmospheres, such as Zone 2.

Group II equipment is used in various surface industries where potentially explosive atmospheres may exist due to the presence of gases, vapors, mists, or combustible specks of dust. The equipment groups, along with the ATEX categories, help in the selection of appropriate equipment suitable for specific hazardous zone classifications, ensuring safety in potentially explosive environments.

Fig 5. Typical ATEX and IECEx marking

Guidelines for installing pressure transmitters in hazardous areas

Installing pressure transmitters in Hazardous Areas requires adherence to strict safety guidelines to minimize risks associated with potentially explosive atmospheres. Here are essential guidelines for installing pressure transmitters in such environments:

- Hazardous Area Classification: Understand the hazardous zone classification (Zone 0, Zone 1, or Zone 2) where the pressure transmitter will be installed. Ensure the transmitter is suitable and certified for that specific hazardous zone.

- ATEX/IECEx Compliance: Choose pressure transmitters with ATEX or IECEx certification, confirming their compliance with safety standards for use in potentially explosive atmospheres.

- Selection of Suitable Transmitters: Select pressure transmitters specifically designed and certified for hazardous areas. Ensure they have the appropriate enclosures or protection to prevent ignition sources in explosive atmospheres.

- Intrinsically Safe Wiring: Use intrinsically safe wiring techniques and barriers to limit electrical energy and prevent sparking or heat generation that could ignite the atmosphere. Follow guidelines for proper wiring and cable management.

- Installation by Qualified Personnel: Only qualified personnel with knowledge of hazardous area regulations should install pressure transmitters. Ensure they follow the manufacturer's installation instructions and comply with safety standards.

- Proper Mounting and Sealing: Install pressure transmitters securely and ensure proper sealing to prevent ingress of hazardous substances. Use suitable sealing materials compatible with the transmitter and the environment.

- Environmental Considerations: Consider factors like temperature, pressure, and the presence of corrosive substances when selecting installation locations and materials. Ensure the transmitter's specifications align with the environmental conditions.

- Regular Inspections and Maintenance: Implement a schedule for regular inspections and maintenance of pressure transmitters in hazardous areas. Check for signs of damage, corrosion, or malfunction and address issues promptly.

- Safety Protocols and Training: Establish and communicate clear safety protocols for working in hazardous areas. Provide adequate training to personnel on handling equipment, using protective gear, and following emergency procedures.

- Documentation and Compliance: Maintain detailed records of installation, compliance certificates, and ongoing maintenance. Ensure compliance with ATEX, IECEx, or other relevant standards and regulations.

Following these guidelines helps ensure the safe installation and operation of pressure transmitters in hazardous areas, reducing the risks associated with potentially explosive atmospheres and maintaining a secure working environment.

What are the Intrinsically safe (IS) and explosion-proof (Ex d) installation techniques?

Both intrinsically safe (IS) and explosion-proof (Ex d) installation techniques are designed to prevent the ignition of flammable atmospheres in hazardous areas. However, they employ different principles to achieve this goal:

- Principle: Intrinsically safe installations focus on limiting electrical energy to a level below that which could cause ignition. This is achieved by using low-energy electrical circuits and devices that cannot produce sparks or temperatures high enough to ignite a flammable atmosphere.

- Method: IS installations use barriers or devices like zener barriers or galvanic isolators to limit current, voltage, and energy levels in electrical circuits. These barriers ensure that even in the event of a fault, the energy transmitted to the hazardous area remains below the ignition threshold.

- Application: Intrinsically safe installations are commonly used in environments with Zone 0, Zone 1, or Zone 2 classifications where the risk of explosive atmospheres is present.

- Principle: Explosion-proof installations aim to contain any explosion that might occur within the equipment itself, preventing it from igniting the surrounding flammable atmosphere.

- Method: Explosion-proof enclosures or housings are constructed to withstand and contain an explosion, ensuring that any sparks or heat generated within the enclosure do not escape and ignite the surrounding atmosphere. These enclosures are robust and designed to withstand the pressure of an explosion without rupturing.

- Application: Explosion-proof installations are suitable for hazardous areas with Zone 1 or Zone 2 classifications, where there is a risk of explosive atmospheres due to the presence of flammable gases, vapors, or combustible bags of dust.

References

https://www.amazon.com/Safety-Pressure-Sensitive-Response-Seating/dp/B0CFVNHM31

https://sleepsense.com/shop/systems/nihon-kohden/ac-pressure-sensor-plus/

https://jcftechnology.com/news_detail.php?menuid=53&id=164

https://moyermarine.com/product/oil-pressure-safety-switch-closes-above-6-psi-2-psi-fpmp_04_46/

https://www.tanksinc.com/index.cfm/page/ptype=product/product_id=782/mode=prod/prd782.htm

https://www.summitracing.com/parts/crt-a68301

https://wessingtoncryogenics.com/pressure-systems-safety-regulations-written-scheme-of-examination/

https://news.nilfiskcfm.com/2017/03/atex-certification-applicable-north-america/

https://www.getac.com/intl/certifications/atex-iecex/

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025