Elevate Your Sensing Game: Piezoelectric Sensor at the Heart of Innovation

Imagine a technology that can transform the physical world into a realm of electrical insights. Piezoelectric sensors, the unsung heroes of modern measurement, hold this power. With the ability to convert pressure, force, and vibration into electric signals, these sensors play a pivotal role in the healthcare and aerospace industries. In this journey, we'll delve into the captivating realm of piezoelectric sensors, unraveling their inner workings, exploring their myriad applications, and uncovering the pros and cons that shape their impact on our ever-evolving world.

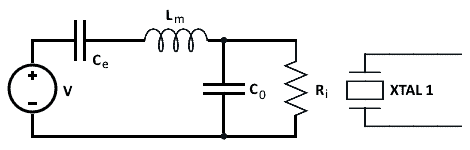

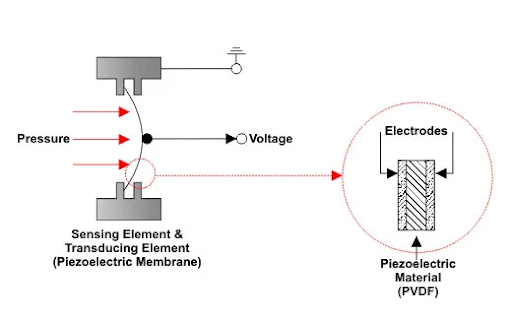

Fig 1. Piezoelectric Sensor Circuit

What is a Piezoelectric Sensor?

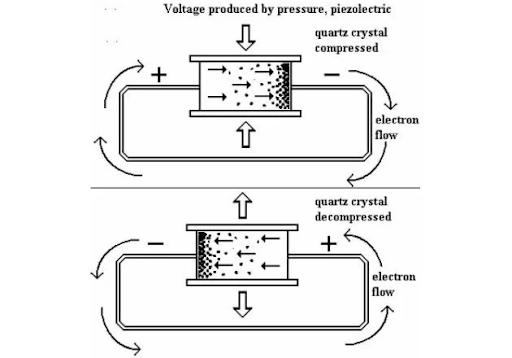

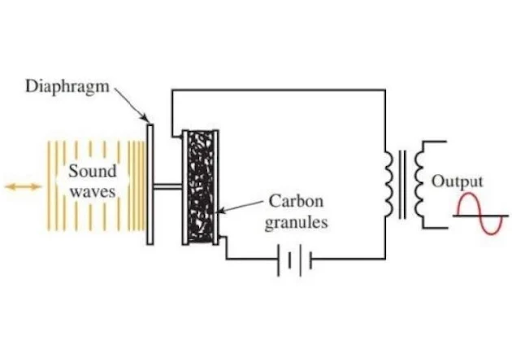

A piezoelectric sensor utilizes the piezoelectric effect to measure changes in pressure, acceleration, temperature, or force by converting these physical changes into electrical signals. The piezoelectric effect refers to the ability of certain materials to generate an electric charge when subjected to mechanical stress or pressure, and conversely, to deform when an electric field is applied to them.

Piezoelectric sensors consist of a piezoelectric material, typically a crystal such as quartz, ceramics like lead zirconate titanate (PZT), or certain polymers. These materials are carefully engineered to exhibit the piezoelectric effect efficiently. When the sensor experiences mechanical deformation due to pressure, acceleration, or force, the piezoelectric material generates a proportional electric charge on its surface. This charge is then measured and converted into an electrical voltage, which can be further processed and analyzed.

These sensors are widely used in various applications, including:

- Pressure Sensing: Piezoelectric pressure sensors are commonly used in industrial, automotive, and medical applications to measure fluid pressure in liquids and gases.

- Accelerometers: Piezoelectric accelerometers are used to measure acceleration and vibrations in machines, vehicles, and structures, enabling monitoring of performance and safety.

- Touch Sensors: Some touch screens and touch-sensitive devices use piezoelectric sensors to detect touch or pressure changes.

- Ultrasonic Devices: Piezoelectric materials are used in ultrasonic transducers for applications like distance measurement, medical imaging, and cleaning.

- Energy Harvesting: Piezoelectric sensors can also work in reverse, converting mechanical vibrations or strains into electrical energy. This principle is used in energy harvesting devices to generate power from ambient vibrations.

- Sonar and Underwater Applications: Piezoelectric sensors are utilized in sonar systems for underwater navigation, mapping, and communication due to their ability to emit and receive ultrasonic signals.

- Medical Imaging: Piezoelectric crystals are used in medical ultrasound devices to create and receive sound waves for imaging internal structures of the body.

- Material Testing and Quality Control: In manufacturing industries, piezoelectric sensors can be used for non-destructive testing, material characterization, and quality control.

Overall, piezoelectric sensors offer advantages such as durability, high sensitivity, wide frequency response, and resistance to electromagnetic interference. They have found applications in diverse fields due to their ability to convert mechanical energy into electrical signals and vice versa.

Find the perfect Pressure Sensor for your specific needs with our easy-to-navigate selection.

When was the first Piezoelectric Sensor made?

The discovery of the piezoelectric effect dates back to the 18th century, but the first practical piezoelectric sensor wasn't developed until much later. Here are some key milestones in the history of piezoelectric sensors:

- Discovery of the Piezoelectric Effect (Late 18th Century): The piezoelectric effect was first observed by scientists such as Pierre and Jacques Curie in the late 19th century. They noticed that certain crystals, including quartz, exhibited electrical charges when subjected to mechanical stress.

- Early 20th Century: In the early 20th century, researchers further explored the piezoelectric effect and its potential applications. The Curie brothers demonstrated the inverse piezoelectric effect, where applying an electric field to certain crystals caused them to change shape.

- 1921: Japanese scientist Kikuharu Takei is credited with creating one of the first practical applications of the piezoelectric effect. He developed a sonar device using a quartz crystal to emit ultrasonic waves and detect their reflections underwater.

- 1932: The first patent for a piezoelectric accelerometer was granted to Cady and Pingree. This accelerometer used a piezoelectric crystal to measure acceleration by converting it into an electrical signal.

- 1940s and Onward: The use of piezoelectric materials in various applications continued to evolve. World War II played a significant role in advancing the development of piezoelectric devices for military applications such as sonar systems.

- 1960s: Piezoelectric sensors started to be used more widely in industrial and scientific applications, including pressure sensors and vibration measurement devices.

- 1980s: With advancements in materials science and electronics, the performance and reliability of piezoelectric sensors improved. They began to find applications in fields like automotive engineering, medical imaging, and consumer electronics.

Since then, piezoelectric sensors have continued to advance in terms of sensitivity, durability, and versatility, enabling their integration into an even wider range of applications across various industries. The evolution of piezoelectric technology has been marked by a continuous cycle of research, development, and innovation, contributing to the sensors' widespread use in modern technology.

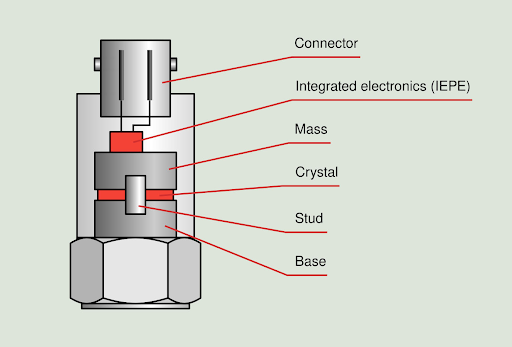

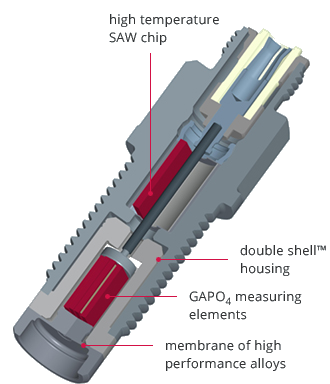

Fig 2. Piezoelectric transducer components

What is a Piezoelectric Pressure Sensor?

A piezoelectric pressure sensor is a type of sensor that uses the piezoelectric effect to measure changes in pressure. It converts mechanical pressure or force applied to it into an electrical signal, which can then be measured and analyzed. These sensors are commonly used to measure fluid pressure in liquids and gases in various industrial, automotive, medical, and consumer applications.

Here's how a piezoelectric pressure sensor generally works:

- Piezoelectric Material: The core of the sensor is a piezoelectric material, often a crystal such as quartz or a piezoelectric ceramic material like lead zirconate titanate (PZT). This material is carefully selected and shaped to exhibit strong piezoelectric properties.

- Pressure Sensing Element: The piezoelectric material is typically designed in a way that it can deform slightly in response to changes in pressure. When pressure is applied to the sensor, the material experiences mechanical stress, causing it to deform or generate a small electric charge.

- Electrodes: The piezoelectric material is coated with electrodes on its surfaces. These electrodes collect the electric charges generated by the piezoelectric effect when the material is deformed due to pressure changes.

- Electric Signal Generation: As the piezoelectric material deforms under pressure, it generates an electric charge imbalance between its electrodes. This charge is proportional to the applied pressure. This charge can be measured as a voltage across the electrodes, and it is often very small. To amplify and process the signal, additional electronics may be used.

- Signal Processing: The generated electrical signal is typically processed by electronic circuitry to amplify, filter, and condition the signal for accurate measurement. Analog-to-digital converters (ADCs) may be used to convert the analog voltage signal into a digital value that can be further processed and analyzed by a microcontroller or computer.

- Output: The final output of the piezoelectric pressure sensor is usually an electrical signal that represents the pressure change. This output can be displayed, recorded, or transmitted to other systems for further analysis or control.

Piezoelectric pressure sensors offer advantages such as high sensitivity, fast response times, and resistance to harsh environments. They are commonly used in applications like automotive engine control, industrial process monitoring, aerospace applications, medical devices (such as blood pressure monitors), and various other pressure measurement scenarios.

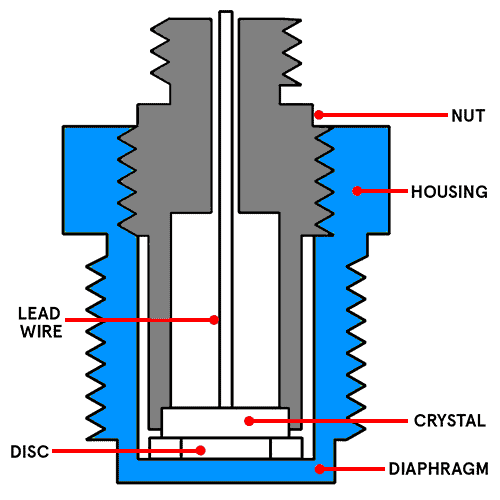

Fig 3. Piezoelectric pressure Sensors

What is a Piezoelectric pressure Sensor made of?

A piezoelectric pressure sensor is primarily composed of several key components that work together to convert mechanical pressure into an electrical signal. The main components include

- Piezoelectric Material: This is the heart of the sensor. The piezoelectric material is chosen for its ability to generate an electric charge when subjected to mechanical stress. Common materials include crystals like quartz and ceramics like lead zirconate titanate (PZT). These materials have a crystalline structure that allows them to exhibit the piezoelectric effect effectively.

- Pressure-Sensitive Element: The piezoelectric material is shaped or designed in a way that it can undergo mechanical deformation in response to changes in pressure. This deformation causes the crystal lattice structure of the material to change slightly, leading to the generation of electric charges on its surface.

- Electrodes: The surfaces of the piezoelectric material are coated with conductive electrodes. These electrodes are used to collect the electric charges generated by the piezoelectric effect when the material deforms due to pressure changes. Typically, there are two electrodes – one positive and one negative – to create an electric field across the material.

- Housing or Casing: The piezoelectric material and its sensitive components need to be protected from external factors such as moisture, dust, and mechanical impacts. The sensor is encased in a housing or casing made of materials like metal, plastic, or ceramic. This casing also ensures that the sensor can be easily installed in different environments.

- Signal Conditioning Electronics: The electrical charge generated by the piezoelectric material due to pressure changes is often very small. Signal conditioning electronics are used to amplify, filter, and condition the signal to make it suitable for measurement and further processing. This can include amplification stages, filtering to remove noise, and possibly analog-to-digital conversion.

- Output Interface: The final output of the piezoelectric pressure sensor is usually an electrical signal that represents the pressure change. This output can be in the form of voltage, current, or digital signal, depending on the design of the sensor and its intended application.

- Connector: The sensor typically features a connector for easy integration with external measurement equipment or control systems. This allows the sensor's output signal to be connected to data acquisition systems, microcontrollers, or other devices for analysis and decision-making.

The precise design and materials used can vary depending on the application and the specific requirements of the sensor. However, the core principle remains the same: the conversion of mechanical pressure into an electrical signal through the piezoelectric effect.

How does a Piezoelectric pressure Sensor work?

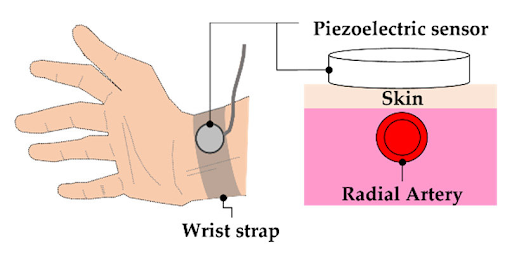

A piezoelectric pressure sensor works based on the principle of the piezoelectric effect, which is the ability of certain materials to generate an electric charge when subjected to mechanical stress or pressure. Here's how a piezoelectric pressure sensor functions:

- Pressure Application: When pressure is applied to the sensor, the piezoelectric material within the sensor undergoes mechanical deformation. This deformation can be caused by changes in force or pressure applied to the sensor's sensitive element. The pressure can come from a liquid, gas, or any substance that needs to be measured.

- Piezoelectric Material Response: As the piezoelectric material deforms due to the applied pressure, the crystal lattice structure of the material changes. This deformation causes a displacement of positive and negative electric charges within the material, resulting in the generation of an electric charge on the material's surfaces. The distribution of these charges creates an electric potential across the material.

- Electric Charge Generation: The generated electric charge accumulates on the electrodes that are attached to the surfaces of the piezoelectric material. One electrode becomes positively charged, while the other becomes negatively charged, creating an electric potential difference between them.

- Electric Signal Formation: The electric potential difference generated by the piezoelectric effect creates an electrical signal that represents the applied pressure. This signal is typically in the form of a voltage across the electrodes. The magnitude of the voltage is proportional to the magnitude of the applied pressure. However, it's important to note that the generated charge is usually very small, so signal conditioning electronics are often required to amplify and process the signal for accurate measurement.

- Signal Processing: The small voltage signal generated by the piezoelectric effect needs to be amplified, filtered, and conditioned to make it suitable for measurement and further processing. Signal conditioning electronics are used to enhance the signal-to-noise ratio and to adapt the signal to the requirements of the measurement equipment.

- Output: The final output of the piezoelectric pressure sensor is an electrical signal that represents the pressure change. Depending on the sensor's design and application, this signal can be displayed, recorded, or transmitted to external devices for further analysis, monitoring, or control.

- Calibration: Piezoelectric pressure sensors often need to be calibrated to provide accurate pressure measurements. This involves relating the electrical output signal to the actual pressure being applied, accounting for any non-linearities or variations in the sensor's response.

In summary, a piezoelectric pressure sensor converts mechanical pressure or force into an electrical signal by utilizing the piezoelectric effect in certain materials. The deformation of the piezoelectric material under pressure generates electric charges, which are then measured and processed to provide an output signal that corresponds to the applied pressure.

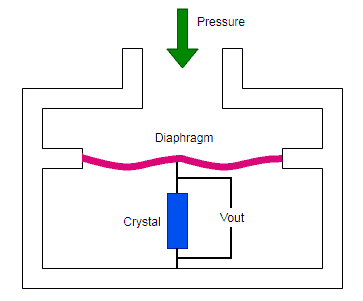

Fig 4. Piezoelectric pressure Sensor working principle

Piezoelectric Sensor Types

Piezoelectric sensors come in various types, each designed to measure different types of physical quantities. Here are some common types of piezoelectric sensors:

- Piezoelectric Pressure Sensors: These sensors measure changes in pressure by converting the applied pressure into an electric charge. They find applications in industries such as automotive, aerospace, medical, and industrial processes.

- Piezoelectric Accelerometers: Accelerometers measure acceleration, vibration, and shock. They are widely used in fields like automotive testing, structural health monitoring, and industrial machinery monitoring.

- Piezoelectric Force Sensors: These sensors measure the force or load applied to them. They can be used to measure tension, compression, or shear forces. Applications include material testing, robotic grippers, and biomechanics.

- Piezoelectric Vibration Sensors: These sensors are specialized accelerometers designed to measure vibrations and oscillations in structures, machines, and equipment. They are crucial for condition monitoring and predictive maintenance.

- Piezoelectric Strain Sensors: These sensors measure changes in mechanical strain or deformation. They find use in structural health monitoring, material testing, and civil engineering applications.

- Piezoelectric Torque Sensors: Torque sensors measure rotational forces or torque applied to an object. They are used in automotive, aerospace, and industrial applications.

- Piezoelectric Temperature Sensors: Although less common, some piezoelectric materials exhibit changes in their piezoelectric properties with temperature fluctuations. These changes can be utilized for temperature measurements in specific environments.

- Piezoelectric Ultrasonic Sensors: These sensors emit and receive ultrasonic waves to measure distance, detect objects, and perform non-destructive testing. They are used in automotive parking systems, medical imaging, and industrial applications.

- Piezoelectric Gas Sensors: These sensors can detect certain gases based on the changes in piezoelectric properties caused by gas absorption. They are used in environmental monitoring and gas detection systems.

- Piezoelectric Touch Sensors: Some touch-sensitive devices use piezoelectric sensors to detect touch or pressure changes. These sensors are commonly found in touch screens and interactive displays.

- Piezoelectric Energy Harvesting Devices: While not strictly sensors, these devices utilize the piezoelectric effect to convert mechanical vibrations or strains into electrical energy. They are used to power low-energy electronic devices from ambient vibrations.

- Piezoelectric Microphones: These microphones use piezoelectric materials to convert sound waves into electrical signals. They are used in specific applications where high sensitivity and resistance to extreme conditions are required.

These are just a few examples of the many types of piezoelectric sensors available. The choice of sensor type depends on the specific application and the physical quantity being measured.

Fig 5. Piezoelectric accelerometer

Comparing table

Here's a comparison table that highlights the key characteristics of different types of piezoelectric sensors:

Table 1. Piezoelectric sensor types

| Sensor Type | Measured Quantity | Applications | Advantages | Challenges |

| Piezoelectric Pressure | Pressure | Automotive, industrial, medical, aerospace | High sensitivity, fast response, ruggedness | Calibration required, limited dynamic range |

| Piezoelectric Accelerometer | Acceleration, Vibration | Automotive, structural monitoring, machinery | High accuracy, broad frequency range | Complex signal processing, sensitivity to noise |

| Piezoelectric Force | Force, Load | Material testing, robotics, biomechanics | Accurate force measurement, small form factor | Calibration, non-uniform loading |

| Piezoelectric Vibration | Vibration | Structural health monitoring, machines | Precise vibration measurement, real-time monitoring | Signal analysis expertise required |

| Piezoelectric Strain | Strain, Deformation | Structural health, material testing | High sensitivity, non-intrusive measurement | Signal conditioning, sensitivity to temperature |

| Piezoelectric Torque | Torque | Automotive, industrial | Direct torque measurement, compact size | Complex installation, calibration |

| Piezoelectric Ultrasonic | Distance, Object Detection | Automotive, medical imaging, NDT | Accurate distance measurement, non-destructive | Frequency tuning, environmental interference |

| Piezoelectric Touch | Touch, Pressure | Touchscreens, interactive displays | High sensitivity, durable | Limited spatial resolution, complex integration |

| Piezoelectric Gas | Gas Detection | Environmental monitoring, gas detection | Specific gas detection, portable | Limited to certain gases, calibration |

| Piezoelectric Energy Harvesting | Mechanical Energy | Low-power devices, remote sensing | Energy from vibrations, self-powered | Energy conversion efficiency, varying sources |

| Piezoelectric Microphone | Sound Waves | Audio recording, noise measurement | High sensitivity, and resistance to harsh environments | Limited frequency range, external noise sensitivity |

Please note that this table provides a general overview of the characteristics and applications of different piezoelectric sensor types. Actual performance and suitability for specific applications can vary based on the design of the sensor, the quality of the piezoelectric material, and other factors.

Piezoelectric Pressure Sensor Types

Piezoelectric pressure sensors come in various types, each designed to meet specific application requirements. Here are some common types of piezoelectric pressure sensors:

- Piezoelectric Diaphragm Pressure Sensors: These sensors use a flexible diaphragm made of a piezoelectric material. When pressure is applied, the diaphragm flexes, causing the piezoelectric material to generate an electric charge. These sensors are used for pressure measurements in various industries.

- Piezoelectric Quartz Pressure Sensors: These sensors use a thin quartz crystal as the piezoelectric material. Changes in pressure deform the quartz crystal, generating an electric charge. Quartz sensors offer high accuracy and stability, making them suitable for precise pressure measurements.

- Piezoelectric Ceramic Pressure Sensors: These sensors use piezoelectric ceramics, such as lead zirconate titanate (PZT), as the sensing element. The ceramic material's piezoelectric properties are utilized to convert pressure changes into electrical signals. They are commonly used in industrial and automotive applications.

- Piezoelectric Resonant Pressure Sensors: These sensors rely on the change in the resonance frequency of a piezoelectric material due to pressure-induced changes in mechanical stress. The shift in resonance frequency is used to determine the applied pressure. They offer high sensitivity and are used in precision applications.

- Piezoelectric Surface Acoustic Wave (SAW) Pressure Sensors: SAW sensors use piezoelectric materials to generate and receive surface acoustic waves. The pressure-induced changes in wave propagation velocity are used to measure pressure. SAW sensors are compact and suitable for wireless applications.

- Piezoelectric MEMS Pressure Sensors: Microelectromechanical systems (MEMS) technology is used to create miniaturized pressure sensors. Piezoelectric materials are integrated into MEMS structures to measure pressure changes. These sensors are commonly found in consumer electronics and automotive applications.

- Piezoelectric Vibration Mode Pressure Sensors: These sensors utilize the vibration modes of a piezoelectric material to measure pressure. Changes in pressure alter the vibration frequencies, which can be correlated to pressure changes. They are used in aerospace and high-pressure applications.

- Piezoelectric Bourdon Tube Pressure Sensors: These sensors use a mechanical component known as a Bourdon tube, which deforms under pressure. The deformation generates mechanical stress on a piezoelectric material, generating an electric charge.

- Piezoelectric Thin Film Pressure Sensors: Thin films of piezoelectric materials are deposited onto substrates to create compact pressure sensors. These sensors are often used in medical devices and other applications where size constraints are critical.

- Piezoelectric Ceramic Resonator Pressure Sensors: These sensors use the resonance frequency of a piezoelectric ceramic resonator to measure pressure changes. The resonance frequency shifts with pressure, enabling pressure measurement.

The choice of piezoelectric pressure sensor type depends on factors such as the required accuracy, sensitivity, temperature range, operating environment, size constraints, and cost considerations specific to the intended application.

Fig 6. Piezoelectric Pressure Sensor

Comparing Table

Here's a comparison table that highlights the key characteristics of different types of piezoelectric pressure sensors:

Table 2. Piezoelectric pressure sensor types

| Sensor Type | Principle | Applications | Advantages | Challenges |

| Diaphragm Pressure Sensors | Deformation of diaphragm | Industrial, automotive, medical | Simple construction, rugged | Limited to moderate pressures, calibration |

| Quartz Pressure Sensors | Deformation of quartz crystal | Precision measurements | High accuracy, stability | Sensitivity to shock and vibration |

| Ceramic Pressure Sensors | Piezoelectric ceramic material | Industrial, automotive | Rugged, withstands harsh environments | Lower accuracy compared to quartz sensors |

| Resonant Pressure Sensors | Changes in resonance frequency | Precision measurements | High sensitivity, stable over time | Complex signal processing |

| SAW Pressure Sensors | Surface acoustic wave propagation | Wireless applications | Compact size, wireless communication | Limited pressure range, sensitivity to temperature |

| MEMS Pressure Sensors | Microfabrication technology | Consumer electronics, automotive | Small size, cost-effective | Limited accuracy for certain applications |

| Vibration Mode Pressure Sensors | Vibration modes of piezoelectric material | Aerospace, high-pressure applications | High sensitivity, resistance to high pressures | Complex design and analysis |

| Bourdon Tube Pressure Sensors | Mechanical deformation of Bourdon tube | Industrial | Rugged construction, suited for high pressures | Limited accuracy, mechanical wear over time |

| Thin Film Pressure Sensors | Thin films of piezoelectric material | Medical devices, compact applications | Small size, suitable for miniaturization | Sensitivity to mechanical stress and temperature |

| Ceramic Resonator Pressure Sensors | The resonance frequency of piezoelectric ceramic | Pressure sensing | High sensitivity, compact size | Limited pressure range, sensitivity to temperature |

Please note that this table provides a general overview of the characteristics and applications of different piezoelectric pressure sensor types. Actual performance and suitability for specific applications can vary based on the design of the sensor, the quality of the piezoelectric material, and other factors.

What is a Piezoelectric Sensor used for?

Piezoelectric sensors are used for a wide range of applications across various industries due to their ability to convert mechanical changes into electrical signals and vice versa. Here are some common applications of piezoelectric sensors:

- Pressure Measurement: Piezoelectric pressure sensors are extensively used to measure pressure in liquids and gases. They find applications in industrial processes, automotive engines, aerospace, and medical devices like blood pressure monitors.

- Vibration and Acceleration Monitoring: Piezoelectric accelerometers are used to measure vibrations and accelerations in machinery, vehicles, buildings, and structures. They help monitor equipment health, detect anomalies, and ensure safety.

- Touch and Force Sensing: Some touch screens and interactive surfaces use piezoelectric sensors to detect touch and pressure changes. They enable devices to respond to touch gestures and varying levels of pressure.

- Ultrasonic Devices: Piezoelectric materials are used in ultrasonic transducers for various applications such as distance measurement, medical imaging, cleaning, and object detection.

- Energy Harvesting: Piezoelectric sensors can be used to convert ambient mechanical vibrations or motion into electrical energy. This energy can power low-energy devices and sensors, especially in remote or challenging environments.

- Temperature Compensation: Certain piezoelectric materials exhibit changes in their properties with temperature variations. They can be used for temperature compensation in electronic circuits and devices.

- Gas and Chemical Sensing: Some piezoelectric materials can interact with specific gases or chemicals, leading to changes in their properties. These materials are used in gas detection and chemical sensing applications.

- Structural Health Monitoring: Piezoelectric sensors are used to monitor the structural health of buildings, bridges, and other infrastructure. They detect changes in strain, deformation, and vibrations that might indicate damage or wear.

- Non-Destructive Testing (NDT): Piezoelectric transducers are employed in ultrasonic testing to detect flaws, cracks, and defects in materials without damaging them. They are commonly used in quality control and inspection processes.

- Underwater Applications: Piezoelectric sensors are used in underwater sonar systems for navigation, mapping, and communication. They emit and receive acoustic signals for underwater sensing.

- Biomedical Imaging: Piezoelectric materials are used in medical ultrasound devices for creating and receiving sound waves to visualize internal structures of the body.

- Aerospace Applications: Piezoelectric sensors are utilized in aerospace industries for pressure measurements, vibration monitoring, and flutter analysis of aircraft components.

- Automotive Engineering: In the automotive industry, piezoelectric sensors are used for fuel injection timing, exhaust gas pressure monitoring, tire pressure monitoring systems (TPMS), and more.

- Consumer Electronics: Piezoelectric sensors are found in consumer electronics like mobile devices, wearables, and gaming controllers for touch sensing, motion detection, and user interaction.

- Industrial Automation: Piezoelectric sensors are used in industrial automation for process control, feedback systems, and quality assurance.

These examples showcase the versatility of piezoelectric sensors and their wide application across numerous fields, ranging from consumer electronics to heavy industries and scientific research.

Fig 7. Piezoelectric Sensor Usage

Piezoelectric Pressure Sensor Applications

Piezoelectric pressure sensors are extensively used in various industries for pressure measurement and monitoring applications. Here are some specific applications where piezoelectric pressure sensors are commonly employed:

- Automotive Industry:

- Engine Control: Monitoring intake and exhaust pressures, fuel injection, and turbocharger performance.

- Tire Pressure Monitoring Systems (TPMS): Detecting changes in tire pressure to ensure optimal tire performance and safety.

- Brake Systems: Monitoring hydraulic brake pressures for efficient braking performance.

- Industrial Process Control:

- Fluid Systems: Monitoring and controlling pressure in pipelines, pumps, and hydraulic systems.

- HVAC Systems: Controlling air pressure in heating, ventilation, and air conditioning systems.

- Aerospace and Aviation:

- Aircraft Pressure Monitoring: Measuring cabin pressure, fuel system pressure, and hydraulic pressure in aircraft.

- Altitude Measurement: Monitoring atmospheric pressure changes for altitude determination.

- Medical Devices:

- Blood Pressure Monitors: Measuring blood pressure using non-invasive or invasive methods.

- Respiratory Equipment: Monitoring airway pressures in ventilators and respiratory devices.

- Energy Industry:

- Oil and Gas: Monitoring pressures in drilling, pipelines, and storage tanks.

- Power Generation: Monitoring steam and gas pressures in turbines and boilers.

- Manufacturing and Quality Control:

- Leak Testing: Detect leaks in containers, pipes, and other sealed systems.

- Industrial Automation: Integrating pressure sensors into automated processes for quality control.

- Hydraulics and Pneumatics:

- Hydraulic Systems: Monitoring fluid pressures in hydraulic systems for machinery and equipment.

- Pneumatic Systems: Controlling and monitoring air pressures in pneumatic devices.

- Environmental Monitoring:

- Weather Stations: Measuring atmospheric pressure to determine weather patterns.

- Water Systems: Monitoring water pressures in distribution networks and water treatment plants.

- Research and Testing:

- Material Testing: Measuring pressure to assess material properties and behavior.

- Fluid Dynamics: Studying fluid flow and pressure distribution in research settings.

- Consumer Electronics:

- Smartphones and Wearables: Incorporating pressure sensors for altimeter and navigation functions.

- Appliances: Monitoring air pressure in appliances like coffee machines and dishwashers.

- Transportation:

- Railways: Monitoring air pressure in braking systems and air suspension systems.

- Maritime: Monitoring fluid pressures in marine vessels' systems.

- Safety and Monitoring Systems:

- Fire Suppression: Detecting changes in pressure in fire suppression systems.

- Security Systems: Monitoring gas and fluid pressure changes for security applications.

Piezoelectric pressure sensors offer accuracy, responsiveness, and durability, making them suitable for a wide range of applications where precise pressure measurements are crucial for operational efficiency, safety, and quality assurance.

Fig 8. Pressure on some crystals generates a surface charge on the crystal. The amount of charge is proportional to the amount of

Maintenance and installation

How can use the Piezoelectric Pressure Sensor?

Using a piezoelectric pressure sensor involves several steps to ensure accurate measurements and proper functionality. Here's a simple guide on how to use a piezoelectric pressure sensor:

- Preparation:

- Understand the pressure range you need to measure and select a suitable piezoelectric pressure sensor with that range.

- Ensure you have the necessary equipment, including signal conditioning devices, data acquisition systems, and power sources.

- Mounting:

- Choose an appropriate location for sensor installation. Consider factors like accessibility, exposure to pressure changes, and mechanical stability.

- Attach the sensor securely using mounting fixtures, adhesives, or other suitable methods. Ensure a tight seal to prevent pressure leaks.

- Wiring:

- Connect the sensor's output wires to the signal conditioning device or data acquisition system according to the sensor's datasheet or manufacturer's guidelines.

- Follow proper wiring practices, ensuring correct polarity and secure connections.

- Signal Conditioning:

- Use signal conditioning equipment to amplify, filter, and condition the small output signal generated by the sensor.

- Adjust signal conditioning parameters based on your measurement requirements and the sensor's specifications.

- Calibration:

- Calibrate the sensor before use to establish a relationship between the sensor's output signal and the actual pressure values.

- Apply known pressure values and record the corresponding sensor output. Use this data to create a calibration curve or equation.

- Data Acquisition:

- Use a data acquisition system to record the sensor's output signal. Ensure proper sampling rates and data recording settings.

- Measurement:

- Apply the pressure you want to measure to the sensor through the appropriate connections or ports.

- The sensor will generate an electrical signal proportional to the applied pressure.

- Data Interpretation:

- Convert the sensor's output signal into meaningful pressure values using the calibration curve or equation.

- Process and analyze the data as needed for your application.

- Validation:

- Validate the accuracy of the sensor's measurements by comparing them to known reference values or standards.

- Perform tests under different pressure conditions to ensure consistent and reliable performance.

- Maintenance:

- Regularly inspect the sensor for physical damage, wear, or signs of degradation.

- Ensure that wiring and connections remain secure and intact.

Remember that the exact steps and equipment needed might vary based on the specific sensor model and application. Always refer to the manufacturer's documentation and guidelines for the correct usage and maintenance of the piezoelectric pressure sensor.

Fig 9. Piezoelectric (crystal) microphone converts the pressure of sound waves into electric signals

How can calibrate the Piezoelectric Pressure Sensor?

Calibrating a piezoelectric pressure sensor involves determining the relationship between the sensor's output signal and the actual pressure values it measures. Here's a step-by-step guide on how to calibrate a piezoelectric pressure sensor:

- Gather Equipment:

- Obtain a reliable and accurate pressure reference standard or calibrator. This could be a precision pressure gauge or a certified pressure source.

- Calibration Setup:

- Set up a controlled environment where you can apply known pressure values to the piezoelectric pressure sensor and the reference standard simultaneously.

- Data Acquisition System:

- Use a data acquisition system to record the output signals from both the piezoelectric pressure sensor and the reference standard.

- Data Collection:

- Apply a range of known pressure values to both the sensor and the reference standard.

- Record the corresponding output signals from both devices.

- Analysis:

- Plot a graph of the piezoelectric sensor's output signal against the corresponding reference pressure values.

- Curve Fitting:

- Analyze the data and determine the mathematical relationship between the sensor's output and the reference pressure values. This could be a linear equation or a higher-order polynomial.

- Calibration Curve/Equation:

- Generate a calibration curve or equation that represents the relationship between the sensor's output signal and the actual pressure values.

- Validation:

- Apply additional pressure values that were not used during calibration to validate the accuracy of the calibration curve or equation.

- Adjustments (if needed):

- If the calibration curve shows deviations from the expected relationship, you might need to adjust the sensor's output signal using correction factors.

- Documentation:

- Document the calibration process, including the calibration curve or equation, reference standard used, validation results, and any adjustments made.

- Apply Calibration:

- Whenever you use the piezoelectric pressure sensor for measurements, apply the calibration curve or equation to convert its output signal into accurate pressure values.

- Regular Recalibration:

- Periodically recalibrate the sensor to ensure ongoing accuracy. Factors like sensor drift and environmental conditions can affect performance over time.

Keep in mind that the calibration process can vary based on the sensor model, the specific pressure range you're working with, and the available calibration equipment. Refer to the manufacturer's guidelines and datasheet for detailed instructions specific to your piezoelectric pressure sensor. If high precision is crucial, involving calibration experts or laboratories with proper calibration equipment is recommended.

Piezoelectric Pressure Sensor Accuracy

The accuracy of a piezoelectric pressure sensor refers to how closely its output readings correspond to the actual pressure values it's measuring. Accuracy is a critical factor in determining the reliability and usefulness of the sensor's measurements. Several factors influence the accuracy of a piezoelectric pressure sensor:

- Calibration: Proper calibration is essential to establish a relationship between the sensor's output signal and the actual pressure values. Accurate calibration ensures that the sensor provides precise measurements across its operating range.

- Linearity: Ideally, a sensor's output should have a linear relationship with the applied pressure. Non-linear behavior can introduce measurement errors, particularly at the extremes of the pressure range.

- Hysteresis: Hysteresis is the difference in sensor output when pressure is applied and then released. It can cause inaccuracies, especially when measuring dynamic pressure changes or when the sensor is subjected to fluctuating conditions.

- Temperature Effects: Piezoelectric materials can be sensitive to temperature changes, affecting their mechanical and electrical properties. Proper temperature compensation is important to maintain accuracy.

- Frequency Response: The sensor's accuracy might vary with frequency, especially in dynamic applications with rapid pressure changes.

- Signal Conditioning: Signal conditioning, including amplification and filtering, can impact accuracy. Poor signal conditioning can introduce noise and distort the output signal.

- Environmental Conditions: External factors like humidity, electromagnetic interference, and vibration can affect sensor accuracy. Some sensors come with environmental protection features to mitigate these effects.

- Mechanical Stress: Mechanical stresses or strains, whether from improper installation or external forces, can influence the sensor's accuracy.

- Resolution: A sensor's resolution (the smallest change it can detect) affects its ability to provide accurate measurements, especially when dealing with small pressure changes.

To evaluate a piezoelectric pressure sensor's accuracy, consider looking at its datasheet specifications, which often include terms like accuracy, non-linearity, hysteresis, and repeatability. It's important to understand these specifications and how they relate to your application's requirements.

When using a piezoelectric pressure sensor, ensure proper calibration, appropriate signal conditioning, and consider environmental factors to maintain accuracy. Regular validation against known reference standards or calibration equipment can help verify the sensor's ongoing accuracy and performance.

Fig 10. Piezoelectric sensor

What are the advantages and disadvantages of Piezoelectric Sensors?

Piezoelectric sensors offer several advantages and disadvantages that make them suitable for specific applications while posing certain challenges. Here's a summary of the key advantages and disadvantages of piezoelectric sensors:

Advantages:

- High Sensitivity: Piezoelectric sensors are known for their high sensitivity to changes in pressure, force, or acceleration. They can detect even small variations in the measured quantity.

- Fast Response Time: Piezoelectric sensors have rapid response times, making them suitable for applications where real-time measurements are crucial.

- Wide Measurement Range: Piezoelectric sensors can cover a broad range of measurement values, making them versatile for various applications that require measurements across different scales.

- Compact Size: Many piezoelectric sensors are compact and lightweight, making them suitable for applications with space constraints or when portability is essential.

- Ruggedness and Durability: Piezoelectric sensors are often designed to withstand harsh environmental conditions, including temperature extremes, vibrations, and mechanical impacts.

- Wide Frequency Range: Piezoelectric sensors can measure rapid changes in vibration and dynamic events across a wide frequency range, making them useful for studying transient phenomena.

- Energy Harvesting: Certain piezoelectric materials can convert mechanical vibrations into electrical energy, enabling them to be used as energy harvesters for low-power devices.

- Non-Intrusive Measurement: In many cases, piezoelectric sensors can measure quantities without direct contact with the object being measured, which can be beneficial in sensitive environments.

Disadvantages:

- Calibration Requirement: Piezoelectric sensors often require careful calibration to ensure accurate measurements, which can be time-consuming and require specialized equipment.

- Temperature Sensitivity: Piezoelectric materials can exhibit changes in properties with temperature fluctuations, potentially affecting sensor accuracy.

- Non-Linearity: The relationship between the input physical quantity and the sensor's output signal might not always be linear, requiring compensation and correction methods.

- Hysteresis: Hysteresis, where the sensor's output differs for the same input value during loading and unloading, can introduce errors if not compensated for.

- Limited Measurement Range: Some piezoelectric sensors might have limitations in terms of their upper and lower measurement ranges, which can restrict their use in certain applications.

- Complex Signal Conditioning: Amplification, filtering, and signal conditioning are often needed to process the small electrical signals generated by piezoelectric sensors.

- Sensitivity to Mechanical Stress: Piezoelectric sensors can be sensitive to mechanical stresses and strains, which can affect their accuracy and reliability.

- Noise Susceptibility: Piezoelectric sensors can be susceptible to electromagnetic interference and other forms of noise, requiring proper shielding and grounding.

When considering the use of piezoelectric sensors, it's important to weigh their advantages against their disadvantages based on the specific requirements of your application. Additionally, proper sensor selection, installation, calibration, and signal conditioning can help mitigate some of the disadvantages and maximize the benefits of using piezoelectric sensors.

How can choose the right Piezoelectric Sensor?

Choosing the right piezoelectric sensor involves considering various factors to ensure that the sensor meets the specific requirements of your application. Here's a step-by-step guide to help you choose the appropriate piezoelectric sensor:

- Define Your Application:

- Clearly understand the type of physical quantity you need to measure (pressure, force, acceleration, etc.).

- Determine the measurement range, accuracy, and resolution required for your application.

- Consider Environmental Conditions:

- Identify the environmental conditions in which the sensor will operate (temperature, humidity, vibration, etc.).

- Choose a sensor that can withstand these conditions without compromising performance.

- Application-Specific Features:

- Consider any specific features your application requires, such as high-frequency response, resistance to corrosive substances, or compatibility with specific materials.

- Sensor Type:

- Select the appropriate type of piezoelectric sensor based on the measured physical quantity (pressure, force, etc.).

- Consider the pros and cons of different sensor types (diaphragm, quartz, ceramic, etc.) for your application.

- Measurement Range and Accuracy:

- Choose a sensor with a measurement range that encompasses your application's expected values.

- Ensure that the sensor's accuracy specifications align with your desired level of measurement precision.

- Calibration and Accuracy Requirements:

- Evaluate the calibration process required for the sensor and consider the availability of calibration equipment.

- Determine if the sensor's accuracy can be adjusted or compensated as needed.

- Signal Conditioning:

- Consider the signal conditioning requirements (amplification, filtering, etc.) needed to convert the sensor's output into meaningful measurements.

- Physical Size and Mounting:

- Ensure that the sensor's physical dimensions and mounting options match the available space and installation requirements of your application.

- Budget:

- Set a budget for the sensor and consider the costs associated with additional equipment (signal conditioning, calibration, etc.).

- Manufacturer Reputation and Support:

- Research the reputation and reliability of the sensor manufacturer.

- Check if the manufacturer provides technical support, documentation, and assistance with sensor selection and integration.

- Test and Validation:

- If possible, conduct tests using a few different sensor options to evaluate their performance in your specific application context.

- Long-Term Considerations:

- Consider the durability and longevity of the sensor, especially if it will be used in critical or high-reliability applications.

- Consult Experts:

- If you're unsure about the best sensor for your application, consult with experts in the field, engineers, or the manufacturer's technical support.

- Documentation and Datasheets:

- Carefully review the sensor's datasheet, specifications, and documentation to ensure it aligns with your requirements.

By systematically considering these factors, you can narrow down your options and select the piezoelectric sensor that best fits your application's needs, providing accurate and reliable measurements.

Fig 11. Piezoelectric sensors

What are the top brands of Piezoelectric Sensors?

Several reputable brands manufacture high-quality piezoelectric sensors for various applications. Keep in mind that brand reputation can change over time, and it's important to check for the latest information and reviews. As of my last knowledge update in September 2021, here are some of the well-known brands in the field of piezoelectric sensors:

- PCB Piezotronics: A leading manufacturer of piezoelectric sensors, accelerometers, and related measurement equipment for various industries including automotive, aerospace, industrial, and research.

- Kistler: Known for its precision measurement solutions, Kistler offers a range of piezoelectric sensors for applications such as automotive testing, industrial monitoring, and biomechanics.

- Honeywell Sensing and IoT: Honeywell offers a wide range of sensors, including piezoelectric sensors, for applications in aerospace, automotive, medical, and industrial fields.

- Meggitt Sensing Systems (formerly Endevco): Meggitt produces piezoelectric sensors and accelerometers for demanding applications in aerospace, defense, automotive, and other industries.

- Dytran Instruments: Dytran specializes in high-performance accelerometers and piezoelectric sensors for applications ranging from automotive testing to structural health monitoring.

- Measurement Specialties (TE Connectivity): This brand offers various types of sensors, including piezoelectric sensors, for applications in industrial, automotive, medical, and consumer electronics.

- OMEGA Engineering: OMEGA provides a range of sensors and instrumentation solutions, including piezoelectric sensors, for industrial and research applications.

- Wilcoxon Sensing Technologies: Wilcoxon focuses on vibration sensors and accelerometers, serving industries such as energy, industrial, and defense.

- DJB Instruments: DJB specializes in accelerometers and dynamic sensors for applications in the aerospace, automotive, and industrial sectors.

- KIMO Instruments: KIMO offers a variety of sensors, including piezoelectric sensors, for applications in industrial measurement and control.

Please note that the availability and reputation of brands may change over time, and new manufacturers may emerge. When considering a piezoelectric sensor brand, it's important to review its product range, customer reviews, technical support, and compatibility with your specific application requirements.

Conclusion

Piezoelectric sensors are remarkable devices that play a crucial role in a wide range of industries and applications. They convert mechanical changes into electrical signals and vice versa, allowing us to measure pressure, force, acceleration, and more with high accuracy and sensitivity. These sensors have found their way into fields such as automotive, aerospace, healthcare, manufacturing, and research due to their unique properties and capabilities.

As you've learned, there are various types of piezoelectric sensors, each designed to suit specific measurement needs. From pressure sensors that monitor industrial processes to accelerometers that detect vibrations in machinery, these sensors have transformed the way we collect data and make informed decisions.

When using piezoelectric sensors, careful consideration of factors like calibration, signal conditioning, and environmental conditions is essential to ensure accurate and reliable measurements. The advantages of piezoelectric sensors, including high sensitivity, fast response times, and ruggedness, are balanced by challenges such as temperature sensitivity, non-linearity, and signal conditioning complexity.

Selecting the right piezoelectric sensor involves understanding your application requirements, and considering factors like measurement range, accuracy, environmental conditions, and available budget. Brands like PCB Piezotronics, Kistler, Honeywell, and more are well-regarded for their quality sensors and reliable support.

In conclusion, piezoelectric sensors continue to drive innovation and advancements across industries, contributing to safer, more efficient, and more accurate measurements in our increasingly interconnected world. Whether you're monitoring structural health, optimizing manufacturing processes, or studying the behavior of materials, piezoelectric sensors offer a versatile and valuable tool for collecting critical data.

To recap

1. What is a piezoelectric sensor?

A piezoelectric sensor is a device that converts mechanical changes, such as pressure, force, or acceleration, into electrical signals. It utilizes the piezoelectric effect in certain materials to generate an electric charge in response to mechanical deformation.

2. How does a piezoelectric sensor work?

Piezoelectric sensors work based on the piezoelectric effect, where certain materials generate an electric charge when subjected to mechanical stress. When pressure or force is applied to the sensor, the piezoelectric material generates a voltage proportional to the applied load.

3. What are the applications of piezoelectric sensors?

Piezoelectric sensors are used for pressure measurement, vibration monitoring, force sensing, touchscreens, ultrasonic imaging, energy harvesting, structural health monitoring, and more in industries like automotive, aerospace, healthcare, and manufacturing.

4. How do I choose the right piezoelectric sensor for my application?

Consider factors such as the type of measurement, measurement range, accuracy, environmental conditions, signal conditioning requirements, and budget when choosing a piezoelectric sensor.

5. What are the advantages of piezoelectric sensors?

Advantages include high sensitivity, fast response time, compact size, ruggedness, wide measurement range, and suitability for high-frequency applications.

6. What are the disadvantages of piezoelectric sensors?

Disadvantages include the need for calibration, sensitivity to temperature changes, non-linear behavior, signal conditioning complexity, and potential hysteresis.

7. How are piezoelectric sensors calibrated?

Piezoelectric sensors are calibrated by comparing their output signal to known reference values under controlled conditions. A calibration curve or equation is then generated to relate the sensor's output to the actual physical quantity being measured.

8. Can piezoelectric sensors generate energy?

Yes, certain piezoelectric materials can convert mechanical vibrations into electrical energy through the reverse piezoelectric effect. These materials are used for energy harvesting in low-power devices.

9. What industries use piezoelectric sensors?

Piezoelectric sensors find applications in automotive, aerospace, healthcare, industrial automation, consumer electronics, energy, research, and more.

10. How do I ensure the accuracy of piezoelectric sensor measurements?

Ensure proper calibration, signal conditioning, and consider temperature compensation. Validate measurements through comparison with known reference values and conduct tests in various conditions.

These FAQs and answers provide a concise overview of key aspects related to piezoelectric sensors and their applications.

References

https://www.electricaltechnology.org/2020/05/piezoelectric-sensor.html

https://www.mdpi.com/1424-8220/21/20/6915

https://www.sciencedirect.com/topics/engineering/piezoelectric-sensor

https://www.electricaltechnology.org/2020/05/piezoelectric-sensor.html

https://power-mi.com/content/piezoelectric-transducers

https://eepower.com/technical-articles/how-the-piezoelectric-effect-is-used-in-sensors/

https://www.sciencedirect.com/topics/engineering/piezoelectric-sensor

https://circuitglobe.com/piezo-electric-transducer.html

https://en.pm-instrumentation.com/piezoelectric-pressure-sensor-0-to-1000-bar-450-c-m5-0-5

Recent Posts

-

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025 -

Single-Stage, Multi-Stage, and Variable Speed Booster Pumps: Which One is Right for You?

1. Introduction Is your shower lacking the invigorating pressure you crave? Do your faucets tri …13th Apr 2025