Empowering Excellence: Discover Capacitance Pressure Sensor

Imagine a sensor that translates the invisible force of pressure into an electrical language, providing a clear understanding of the world around us. Welcome to the realm of capacitance pressure sensors, where science meets practicality in a sleek, unassuming design. These sensors are like digital barometers, silently deciphering changes in pressure by tapping into the intricate dance of capacitance – the charge storage ability of a capacitor. With a single goal in mind – accurate pressure measurement – these sensors use their ingenious design to detect even the subtlest shifts in pressure, from the industrial floor to the inner workings of our everyday devices. In this fascinating realm, diaphragms deform, electrodes play their part, and electronic circuitry whispers the language of pressure, bringing us closer to understanding and controlling the forces that shape our world.

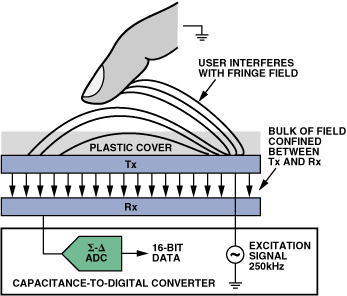

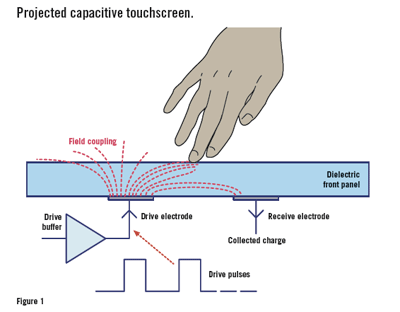

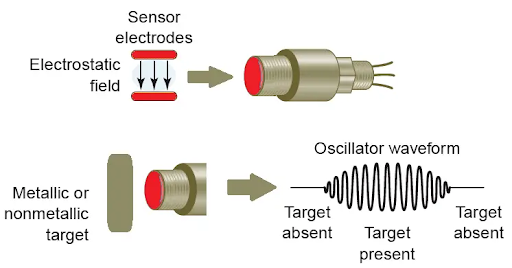

Fig 1. Sensing Capacitance

Which electronic device is called a "Capacitance Sensor"?

A capacitance sensor is an electronic device used to measure the capacitance of an object or a material. Capacitance is the ability of a component to store an electrical charge. These sensors are commonly used in various applications, such as touchscreens, proximity sensing, humidity sensing, and level sensing in liquids. In touchscreens, for instance, capacitance sensors can detect the presence of a conductive object (like a human finger) by measuring the change in capacitance when the object comes into contact with the sensor's surface.

Capacitance Pressure Sensors are essential tools for many industrial applications, but for a wider range and more advanced features, Check Pressure Sensor Products.

What is a Capacitance Pressure Sensor?

A capacitance pressure sensor is a type of sensor that measures pressure by detecting changes in capacitance. Pressure sensors are widely used to monitor and control pressure in various applications, ranging from industrial processes to automotive systems and medical devices. Capacitance pressure sensors utilize the principle of capacitance, which is the ability of a capacitor to store an electric charge.

In a capacitance pressure sensor, a diaphragm or membrane is exposed to the pressure being measured. As the pressure changes, the diaphragm undergoes deformation, resulting in a change in the distance between the diaphragm and a fixed electrode or a second diaphragm. This change in distance leads to a change in the capacitance between the electrodes.

The sensor's electronic circuitry measures this change in capacitance and converts it into an output signal that corresponds to the pressure applied. By calibrating the sensor and correlating its output with known pressure values, it becomes possible to accurately determine the pressure being measured.

Capacitance pressure sensors have various applications in industries such as manufacturing, aerospace, automotive, medical, and more. They are favored for their accuracy, sensitivity, and ability to measure pressure without mechanical contact. Different types of capacitance pressure sensors include absolute pressure sensors, differential pressure sensors, and piezoelectric pressure sensors, each designed to suit specific measurement requirements.

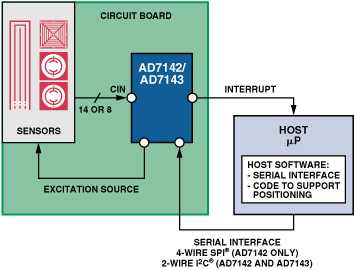

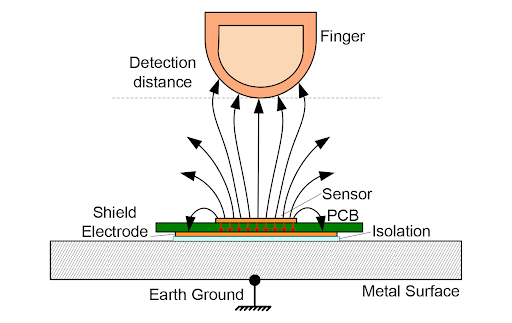

Fig 2.Three-part capacitance-sensing solution

When was the first Capacitance Sensor manufactured?

The concept of capacitance and capacitance sensing has been known for a long time, dating back to the early development of electronics and electrical engineering principles. However, it's challenging to pinpoint an exact date for the first manufactured capacitance sensor, as early developments were likely experimental and not widely documented.

Capacitance sensing technology has evolved, and the first practical applications of capacitance sensors can be traced back to the mid-20th century. For example, early touch-sensitive devices that utilized capacitance sensing were developed in the 1960s and 1970s. These devices were often simple and not as sophisticated as modern capacitive touchscreens, but they laid the foundation for the technology we use today.

As technology progressed, capacitance sensing became more refined and began to be integrated into various electronic devices, particularly in the context of human-machine interfaces. The modern capacitive touchscreens that we commonly see on smartphones and tablets became popular in the late 2000s and early 2010s.

While the exact date of the first manufactured capacitance sensor is difficult to pinpoint, the technology's development and refinement have been ongoing for several decades, leading to the capacitive sensing technology we have today.

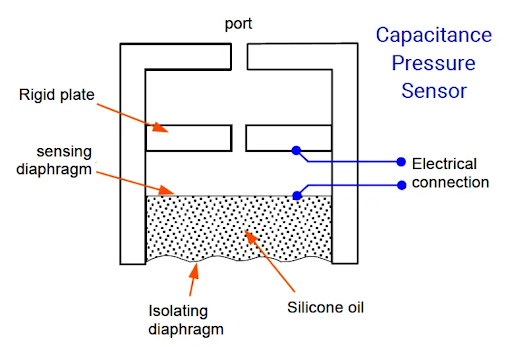

Capacitance pressure sensor Structure

The structure of a capacitance pressure sensor is designed to convert the physical pressure applied to the sensor into a measurable electrical signal. It typically consists of several key components that work in harmony to achieve this conversion. While the exact structure can vary based on the sensor's design and manufacturer, here is a generalized overview of the components you might find in a capacitance pressure sensor:

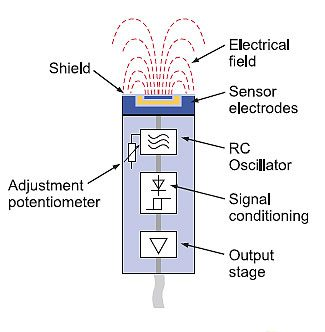

- Diaphragm or Membrane: The diaphragm is a thin, flexible component that is directly exposed to the pressure being measured. It responds to pressure changes by deforming, either moving closer to or farther away from the electrode(s) within the sensor. The diaphragm's deformation alters the capacitance between the electrodes, which is the fundamental principle exploited by the sensor.

- Electrodes: Electrodes are conductive surfaces placed on either side of the diaphragm, forming a capacitor. These electrodes can be fixed (stationary) or movable (forming a differential capacitance configuration). The distance between the electrodes changes as the diaphragm deforms due to pressure, leading to changes in capacitance.

- Dielectric Material: The dielectric material is the medium between the electrodes, typically air or a non-conductive material. It influences the capacitance value by affecting the distance between the electrodes and the permittivity of the material.

- Support Structure: The sensor often includes a support structure that holds the diaphragm and electrodes in place while allowing the diaphragm to deform in response to pressure. The support structure might also provide mechanical protection to the sensitive components.

- Sealing and Encapsulation: To protect sensitive internal components from environmental factors such as moisture, dust, and chemicals, capacitance pressure sensors are often sealed within protective enclosures.

- Electronics and Signal Processing: The sensor's electronic circuitry amplifies, processes, and converts the change in capacitance into an output signal that represents the pressure being measured. This could involve analog-to-digital conversion, signal conditioning, and output formatting.

- Calibration Mechanism (optional): Some sensors have a calibration mechanism that allows for fine-tuning the sensor's output to match known reference pressures. This helps improve accuracy.

- Wiring and Connectors: Wiring connects the sensor's circuitry to external electronics for power supply, signal processing, and data acquisition.

- Housing and Mounting: The sensor is typically housed in a protective casing that can be easily mounted or integrated into various systems or applications.

The combination of these components enables the capacitance pressure sensor to accurately detect pressure variations and convert them into useful electrical signals. The structural design may vary based on the specific application and manufacturer, but the fundamental principle of using capacitance changes to measure pressure remains consistent.

Fig 3. Capacitance sensor internal construction

How does a Capacitance pressure Sensor work?

A capacitance pressure sensor works by utilizing the change in capacitance between two conductive surfaces to measure the pressure applied to the sensor. This type of sensor is commonly used to monitor and quantify pressure variations in various applications. Here's a step-by-step explanation of how a capacitance pressure sensor works:

- Sensor Structure: A capacitance pressure sensor consists of a flexible diaphragm or membrane, electrodes, and electronic circuitry. The diaphragm is designed to deform in response to changes in pressure, while the electrodes are positioned on either side of the diaphragm.

- Initial State: In its initial state (no pressure applied), the diaphragm rests at a specific distance from the electrodes, and there is a certain capacitance between them.

- Pressure Application: When pressure is applied to the sensor, the diaphragm responds by deforming. If the pressure is external and higher than the pressure on the other side of the diaphragm (as in the case of absolute pressure sensors), the diaphragm might move closer to the electrodes.

- Change in Capacitance: The deformation of the diaphragm alters the distance between the electrodes. Since capacitance is inversely proportional to the distance between the conductive surfaces, the change in distance leads to a change in capacitance.

- Capacitance Measurement: The electronic circuitry within the sensor measures the new capacitance resulting from the pressure-induced deformation of the diaphragm. This measurement is converted into an electrical signal.

- Signal Conversion: The analog signal representing the change in capacitance is typically converted into a digital signal using an analog-to-digital converter (ADC). This digital signal is then processed and potentially scaled to provide meaningful pressure readings.

- Calibration (if applicable): Some sensors require calibration to correlate the change in capacitance with specific pressure values. Calibration ensures that the sensor's output accurately reflects the pressure applied.

- Output: The final output of the sensor is an electrical signal, often provided as a voltage or current value. This output signal can be interpreted, displayed, or further processed by external devices, such as controllers, displays, or data acquisition systems.

By observing and analyzing the change in capacitance caused by the deformation of the diaphragm under pressure, capacitance pressure sensors can provide accurate and real-time pressure measurements. These sensors are widely used in various industries for applications such as industrial process control, automotive systems, medical devices, and more, where precise pressure monitoring is essential for optimal performance, safety, and quality control.

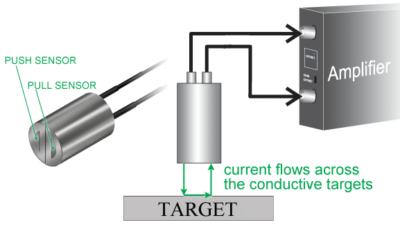

Fig 4. Capacitance sensors

Capacitance Sensor formulas

There are a few key formulas related to capacitance and capacitance sensors that are useful for understanding and designing such sensors. Here are some of the fundamental formulas:

- Capacitance Formula:The capacitance (C) between two parallel plates with area (A) and separated by a distance (d) and filled with a dielectric material of relative permittivity (εᵣ) can be calculated using the following formula:

C = (εᵣ * ε₀ * A) / d

Where:

- C is the capacitance.

- εᵣ is the relative permittivity (dielectric constant) of the material between the plates.

- ε₀ is the vacuum permittivity (8.854 x 10^-12 F/m), a constant.

- A is the area of the plates.

- d is the distance between the plates.

- Capacitive Touch Sensing Formula:For a simple capacitive touch sensor, the change in capacitance due to a conductive object (like a human finger) approaching the sensor's electrode can be approximated using the following formula:

ΔC = k * A / d

Where:

- ΔC is the change in capacitance.

- k is a constant that depends on the sensor's design and the dielectric properties.

- A is the area of the sensor's electrode.

- d is the distance between the electrode and the object.

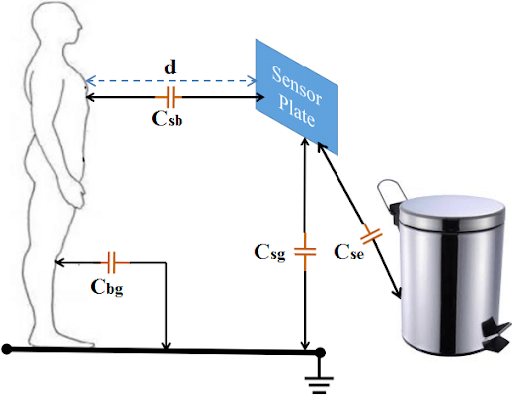

- Capacitive Proximity Sensing Formula:For capacitive proximity sensors, which detect the presence or proximity of an object without physical contact, the change in capacitance can be related to the distance (x) between the sensor and the object using a formula like

ΔC = k / x^2

Where:

- ΔC is the change in capacitance.

- k is a constant related to the sensor's properties.

- x is the distance between the sensor and the object.

These formulas provide simplified relationships between capacitance, changes in capacitance, and various sensor parameters. In practice, more complex sensors use additional circuitry and techniques to improve accuracy, sensitivity, and noise immunity. Additionally, mutual capacitance and self-capacitance configurations are often employed in touchscreens and proximity sensors, involving more advanced formulas and calculations.

Keep in mind that the actual implementation of capacitance sensors involves various factors, including the sensor's geometry, materials, circuitry, and environmental conditions. Formulas can be adapted and refined based on these factors to provide more accurate results.

Formula examples

here are a couple of examples of capacitance sensor formulas in different contexts:

- Capacitive Touchscreen Sensing:Let's say you have a simple capacitive touchscreen sensor with an electrode area of 100 square centimeters and a distance of 0.2 centimeters between the electrode and a conductive object (like a finger). The dielectric properties and constants are not given, so let's assume a simplified scenario where the change in capacitance is proportional to the change in distance:ΔC = k * A / dGiven:

- A (electrode area) = 100 cm²

- d (distance) = 0.2 cm

- Assume k = 1 (a simplified constant)

- Plugging in the values:ΔC = 1 * 100 cm² / 0.2 cm = 500 cm²This means that the change in capacitance due to the finger's approach is 500 cm². In a real-world scenario, the constant "k" would be determined by the sensor's properties and the dielectric properties of the materials involved.

- Capacitive Proximity Sensing:Consider a capacitive proximity sensor that's designed to detect objects within a certain range. The change in capacitance is inversely proportional to the square of the distance between the sensor and the object:ΔC = k / x^2Given:

- Assume k = 10 (a simplified constant)

- x (distance) = 5 cm

- Plugging in the values:ΔC = 10 / (5 cm)^2 = 10 / 25 cm² = 0.4In this case, the change in capacitance due to an object's proximity is 0.4. This value indicates the relative change in capacitance, and its interpretation would depend on the specific sensor calibration and application.

Remember, these examples are simplified and illustrative. In real-world applications, capacitance sensor design involves more complex calculations, consideration of dielectric constants, sensitivity adjustments, and noise handling. It's important to work with accurate sensor specifications and possibly consult sensor datasheets or simulation tools for more precise calculations.

Formula table

Here's a table summarizing the key formulas related to capacitance and capacitance sensors:

Table 1. Formula table

| Formula | Description |

| Capacitance Formula | |

| C = (εᵣ * ε₀ * A) / d | Calculates capacitance between two parallel plates. |

|

C: Capacitance

εᵣ: Relative permittivity ε₀: Vacuum permittivity A: Area of the plates d: Distance between plates |

Constant (8.854 x 10^-12 F/m) |

| Capacitive Touch Sensing Formula | |

| ΔC = k * A / d | Approximate change in capacitance due to touch. |

|

ΔC: Change in capacitance

k: Proportional constant A: Area of the electrode d: Distance between electrodes |

Depends on the sensor and dielectric properties. |

| Capacitive Proximity Sensing Formula | |

| ΔC = k / x^2 | Relates change in capacitance to proximity distance. |

|

ΔC: Change in capacitance

k: Proportional constant x: Distance between sensor |

Depends on sensor properties. |

Please note that these formulas provide simplified relationships and are often used as starting points for designing and understanding capacitance sensors. Real-world sensor design involves additional factors, circuitry, and calibration. Always refer to specific sensor documentation and consider the actual properties of the materials and components involved for accurate calculations.

Fig 5. Proximity sensor

How many types do Capacitance Sensors have?

Capacitance sensors can be categorized into various types based on their applications, configurations, and operating principles. Here are some common types of capacitance sensors:

- Proximity Sensors: Capacitance proximity sensors detect the presence or absence of an object within a certain range without physical contact. They measure changes in capacitance caused by the object's dielectric properties altering the electric field around the sensor. These sensors are used in applications like industrial automation, robotics, and touchless interfaces.

- Capacitive Touch Sensors: These sensors are used in touchscreens and touch-sensitive surfaces. They detect the presence of a conductive object (like a finger) by measuring the changes in capacitance caused by the object's touch. Capacitive touch sensors are widely used in consumer electronics for devices like smartphones, tablets, and interactive displays.

- Humidity Sensors: Capacitance humidity sensors measure the changes in capacitance caused by the absorption or release of moisture by a dielectric material. As humidity levels change, the dielectric properties of the material change, leading to variations in capacitance. These sensors are used in weather stations, HVAC systems, and industrial processes.

- Level Sensors: Capacitance level sensors measure the level of a liquid or solid material within a container. The capacitance changes as the material's dielectric properties come in contact with the sensor's electrode. These sensors are used in tanks, silos, and other storage systems.

- Pressure Sensors: Some pressure sensors use the capacitance principle to measure pressure changes. The deflection of a diaphragm due to pressure causes changes in the capacitance between the diaphragm and another electrode. These sensors find applications in pressure monitoring in various industries.

- Gas and Liquid Composition Sensors: Changes in the dielectric properties of a gas or liquid due to changes in composition can be detected using capacitance sensors. These sensors are used to analyze and monitor the composition of gases or liquids, such as in chemical analysis or environmental monitoring.

- Microwave and Radar Sensors: Certain microwave and radar sensors utilize the capacitance principle to measure changes in capacitance caused by objects entering the sensor's field. These sensors are used in motion detection, security systems, and automotive applications.

- Capacitive Displacement Sensors: These sensors measure changes in capacitance to determine the displacement or movement of an object. They are used in applications where precise measurement of displacement or position is required.

- Touchpads and Gesture Recognition Sensors: Similar to touchscreens, touchpads, and gesture recognition sensors use capacitance to detect touch and gestures. They are employed in devices like laptops, trackpads, and interactive panels.

These are just a few examples of the types of capacitance sensors. The field of capacitance sensing continues to evolve, leading to new applications and sensor designs. The choice of sensor type depends on the specific application's requirements for sensitivity, accuracy, range, and environmental conditions.

Fig 6. Capacitive touchscreen

What are the Capacitance pressure Sensor types?

Capacitance pressure sensors, also known as capacitive pressure sensors, are devices that measure pressure by utilizing changes in capacitance due to the deformation of a diaphragm or sensing element caused by the applied pressure. These sensors are commonly used in various industries for pressure measurement and monitoring. There are several types of capacitive pressure sensors based on their construction and operating principles:

- Diaphragm-Based Capacitive Pressure Sensor: This type of sensor consists of a flexible diaphragm that deflects under applied pressure. The diaphragm is placed between two capacitive plates. As the diaphragm deforms due to pressure, the distance between the plates changes, altering the capacitance. This change in capacitance is proportional to the applied pressure.

- Absolute Capacitive Pressure Sensor: Absolute pressure sensors measure the pressure relative to a vacuum or absolute zero. In an absolute capacitive pressure sensor, the pressure to be measured is applied to one side of the diaphragm, while the other side is exposed to a reference vacuum. The deformation of the diaphragm due to the difference in pressure causes a change in capacitance.

- Differential Capacitive Pressure Sensor: Differential pressure sensors measure the difference in pressure between two points. In a differential capacitive pressure sensor, the diaphragm is exposed to the pressure to be measured on one side and a reference pressure on the other side. The pressure difference causes the diaphragm to deform, leading to a change in capacitance.

- Piezoelectric Capacitive Pressure Sensor: Some capacitive pressure sensors use a piezoelectric material as part of the diaphragm structure. When pressure is applied, the piezoelectric material generates an electric charge, which can be detected as a change in capacitance. These sensors combine the capacitance and piezoelectric effects for pressure measurement.

- Microelectromechanical Systems (MEMS) Capacitive Pressure Sensor: MEMS technology enables the fabrication of miniature pressure sensors with high precision. MEMS capacitive pressure sensors often use silicon diaphragms and microstructures to achieve sensitivity and accuracy in a compact form factor.

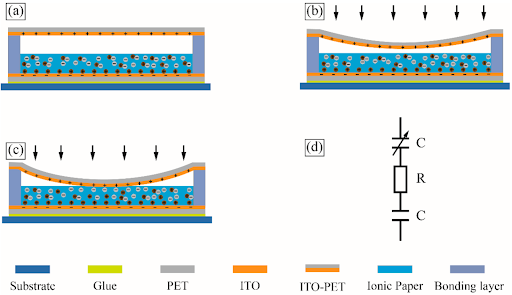

- Flexible Membrane Capacitive Pressure Sensor: Some sensors use flexible membranes made from elastomers or other flexible materials. These sensors are used in applications where the sensor needs to conform to irregular surfaces or where flexibility is important.

- Miniature Capacitive Pressure Sensor: These sensors are designed for applications where space is limited. They often utilize MEMS technology to create small and precise pressure sensors suitable for compact devices.

Each type of capacitive pressure sensor has its advantages and limitations, and the choice of sensor depends on factors such as the required pressure range, sensitivity, accuracy, temperature range, and the specific demands of the application.

Fig 7. Proximity sensor

- Working Principle: A flexible diaphragm deforms under applied pressure, changing the distance between two capacitive plates. This change in distance alters the capacitance, which is then used to determine the pressure.

- Pressure Range: Low to moderate pressure ranges.

- Formula: ΔC = k * A / d, where ΔC is the change in capacitance, k is the proportional constant, A is the area of the diaphragm, and d is the distance between plates.

- Applications: Automotive systems, HVAC, industrial automation, medical devices.

- Pros: Simplicity, reasonable accuracy, good sensitivity to small pressure changes.

- Cons: Limited to moderate pressure ranges, may require compensation for temperature effects.

- Working Principle: Measures the absolute pressure by comparing the pressure side to a vacuum reference.

- Pressure Range: Wide range, from vacuum to atmospheric pressure.

- Formula: Similar to diaphragm-based sensors, ΔC = k * A / d.

- Applications: Altitude measurement, weather stations, vacuum systems.

- Pros: Provides absolute pressure measurements, suitable for a wide range of pressures.

- Cons: Requires a reference vacuum, complexity in design, and calibration.

- Working Principle: Measures the pressure difference between two points by comparing the pressures on each side of the diaphragm.

- Pressure Range: Wide range, depending on the specific application.

- Formula: Similar to other types, ΔC = k * A / d.

- Applications: Flow measurement, filter monitoring, level measurement.

- Pros: Measures pressure differences accurately, versatile application.

- Cons: Requires proper calibration, and sensitivity to temperature differences.

- Working Principle: Uses piezoelectric material in the diaphragm to generate an electric charge proportional to the pressure-induced deformation.

- Pressure Range: Moderate to high-pressure ranges.

- Formula: Combination of piezoelectric and capacitance effects.

- Applications: Industrial process control, hydraulic systems, aerospace.

- Pros: Combines piezoelectric and capacitance effects for enhanced accuracy.

- Cons: More complex designs, may require temperature compensation.

- Working Principle: Utilizes MEMS technology to create miniature structures that deform under pressure, affecting capacitance.

- Pressure Range: Wide range, depending on design and application.

- Formula: Similar to other types, ΔC = k * A / d.

- Applications: Consumer electronics, medical implants, automotive safety systems.

- Pros: Miniaturization, high sensitivity, can be integrated into complex systems.

- Cons: Sensitivity to manufacturing variations, potential for mechanical failure.

- Working Principle: Utilizes a flexible membrane to deform under pressure, affecting capacitance.

- Pressure Range: Moderate to high-pressure ranges.

- Formula: Similar to other types, ΔC = k * A / d.

- Applications: Pressure mapping in biomechanics, conformal pressure sensing.

- Pros: Conforms to irregular surfaces, suitable for dynamic pressure measurements.

- Cons: May require complex fabrication methods, and lower accuracy compared to traditional sensors.

- Working Principle: Often employs MEMS technology to create compact pressure-sensitive structures.

- Pressure Range: Moderate to high-pressure ranges, depending on the design.

- Formula:Similar to other types, ΔC = k * A / d.

- Applications: Wearable devices, microfluidics, embedded systems.

- Pros: Space-saving, suitable for portable and miniature devices.

- Cons: Potential limitations in pressure range and accuracy.

Diaphragm-Based Capacitive Pressure Sensor:

Absolute Capacitive Pressure Sensor:

Differential Capacitive Pressure Sensor:

Piezoelectric Capacitive Pressure Sensor:

Microelectromechanical Systems (MEMS) Capacitive Pressure Sensor:

Flexible Membrane Capacitive Pressure Sensor:

Miniature Capacitive Pressure Sensor:

Each type of capacitive pressure sensor has its strengths and weaknesses, making it suitable for specific applications. The choice of sensor type depends on factors such as the required pressure range, accuracy, size constraints, environmental conditions, and budget considerations.

Fig 8. Capacitance pressure sensor

Comparing table

Here's a comparison table summarizing the different types of capacitive pressure sensors based on various factors:

Table 2. Capacitance pressure sensor types comparison

| Aspect | Diaphragm-Based | Absolute | Differential | Piezoelectric | MEMS | Flexible Membrane | Miniature |

| Working Principle | Diaphragm deformation changing capacitance | Comparison to vacuum reference | Comparison between pressures | Piezoelectric material generating charge | MEMS technology creating miniature structures | Flexible membrane deforming | MEMS technology creating compact structures |

| Pressure Range | Low to moderate | Wide < | Wide | Moderate to high | Wide | Moderate to high | Moderate to high |

| Formula | ΔC = k * A / d | Similar to diaphragm-based | ΔC = k * A / d | Combination of piezoelectric and capacitance effects | Similar to other types | Similar to other types | Similar to other types |

| Applications | Automotive, HVAC, industrial | Altitude, weather, vacuum | Flow, level, differential pressure | Industrial, hydraulic, aerospace | Consumer electronics, medical, automotive | Biomechanics, conformal pressure sensing | Wearable, microfluidics, embedded systems |

| Pros | Simplicity, good sensitivity | Absolute pressure measurement | Measures pressure difference accurately | Combines effects for enhanced accuracy | Miniaturization, high sensitivity | Conforms to irregular surfaces | Space-saving, suitable for miniature devices |

| Cons | Limited pressure range | Requires reference vacuum | Requires calibration, temperature sensitivity | Complex design, potential mechanical failure | Sensitivity to manufacturing variations | Lower accuracy compared to traditional sensors | Potential limitations in pressure range |

| Suitable for | General pressure measurement | Absolute pressure measurement | Pressure difference measurement | Applications requiring high accuracy | Miniaturized devices, embedded systems | Dynamic pressure mapping, conformal sensing | Compact and portable devices |

Please note that this table provides a general overview and comparison of the different types of capacitive pressure sensors. Actual sensor performance and suitability can vary based on specific designs, manufacturing processes, and other factors. It's important to consider the specific requirements of your application when selecting a pressure sensor type.

Fig 9. The sensing principle of the flexible ionic liquid super-capacitive pressure sensor

Capacitance pressure Sensor applications

Capacitance pressure sensors are widely used in various industries for pressure measurement and monitoring applications. Their ability to measure pressure by detecting changes in capacitance due to diaphragm deformation makes them suitable for a range of environments and scenarios. Here are some common applications of capacitance pressure sensors:

- Industrial Process Control: Capacitance pressure sensors are used in industrial settings to monitor and control pressure in manufacturing processes. They ensure that pressure within systems is within safe and optimal operating ranges.

- Aerospace and Aviation: Capacitance pressure sensors are utilized in aerospace applications for altitude measurement, cabin pressure monitoring, and engine pressure monitoring.

- Automotive Industry: These sensors are used in automotive systems, including tire pressure monitoring systems (TPMS), airbag deployment systems, fuel injection systems, and engine management.

- HVAC Systems: Capacitance pressure sensors are employed in heating, ventilation, and air conditioning (HVAC) systems to monitor pressure within ducts and pipes, helping to optimize airflow and temperature control.

- Medical Devices: In medical equipment, capacitance pressure sensors are used in devices such as infusion pumps, respiratory equipment, and patient monitoring systems to ensure proper pressure settings.

- Hydraulic Systems: Capacitance pressure sensors are employed in hydraulic systems to monitor hydraulic pressure levels, ensuring efficient operation of heavy machinery and equipment.

- Oil and Gas Industry: These sensors are used in oil and gas exploration and production for monitoring pipeline pressure, wellhead pressures, and reservoir pressures.

- Environmental Monitoring: Capacitance pressure sensors are used in weather stations, barometers, and other environmental monitoring devices to measure atmospheric pressure changes.

- Pneumatics: Capacitance pressure sensors are used in pneumatic systems to monitor air pressure and control pneumatic actuators in industrial automation.

- Food and Beverage Industry: Capacitance pressure sensors are employed in food processing and bottling plants to monitor pressure in various stages of production and packaging.

- Water Management: These sensors are used in water treatment facilities, wastewater management, and irrigation systems to monitor pressure in pipelines and distribution networks.

- Pharmaceutical Industry: Capacitance pressure sensors are used in pharmaceutical manufacturing processes to ensure accurate pressure control and consistency in production.

- Laboratory Equipment: These sensors are utilized in laboratory instruments like chromatography systems, where precise pressure control is crucial for accurate analysis.

- Research and Development: Capacitance pressure sensors play a role in research and development for studying pressure effects in different materials and systems.

- Energy Generation: In power plants, capacitance pressure sensors are used to monitor pressure in steam turbines, boilers, and other critical components.

The flexibility, accuracy, and versatility of capacitance pressure sensors make them valuable tools in numerous industries where pressure measurement is essential for safety, efficiency, and quality control.

Installation and maintenance

How can use the Capacitance Sensor?

Using a capacitance pressure sensor involves several steps to ensure accurate measurements and reliable operation. Here's a general guide on how to use a capacitance pressure sensor effectively:

- Preparation:

- Familiarize yourself with the sensor's datasheet, user manual, and specifications.

- Ensure you have the necessary equipment, including power supply, signal processing circuitry, and any calibration tools.

- Sensor Installation:

- Mount the sensor securely in a suitable location, ensuring proper alignment with the pressure source.

- Ensure that the diaphragm or sensing surface of the sensor is exposed to the pressure you intend to measure.

- Electrical Connections:

- Connect the sensor to a compatible power supply following the manufacturer's guidelines.

- Connect the sensor's output to signal processing circuitry, such as an analog-to-digital converter (ADC) or microcontroller.

- Calibration (if applicable):

- If your sensor requires calibration, follow the manufacturer's calibration procedure.

- Use known reference pressures to adjust the sensor's output to accurate pressure values.

- Data Interpretation and Processing:

- Configure the signal processing circuitry to interpret the sensor's output signal.

- Implement scaling factors if necessary to convert the output signal to pressure units (e.g., psi, kPa).

- Testing and Validation:

- Apply different pressure levels to the sensor and compare the output readings to expected values.

- Verify that the sensor responds accurately to pressure changes within its specified range.

- Integration:

- Integrate the sensor's output into your system or application. This might involve displaying pressure readings on a screen, triggering alarms, or controlling processes based on the sensor's data.

- Environmental Considerations:

- Ensure that the sensor's operating environment meets its specifications. Factors like temperature, humidity, and electromagnetic interference can affect sensor performance.

- Maintenance and Monitoring:

- Regularly check the sensor for signs of wear, contamination, or damage.

- Perform periodic calibrations to maintain accuracy, especially if the sensor's performance is critical to your application.

- Data Analysis (for monitoring applications):

- If the sensor is used for continuous monitoring, collect and analyze data over time to identify trends, patterns, or anomalies in the pressure readings.

- Troubleshooting:

- If you encounter unexpected readings or issues, refer to the manufacturer's troubleshooting guide or seek technical support.

Always refer to the sensor's documentation and guidelines specific to your sensor model and application. If you're unsure about any aspect of using the capacitance pressure sensor, consider consulting with experts or professionals who have experience with similar sensors or applications.

Fig 10. Capacitance sensor

Capacitance pressure Sensor Calibration

Calibration is a critical process for ensuring that your capacitance pressure sensor provides accurate and reliable pressure measurements. Proper calibration helps align the sensor's output with known reference values, compensating for any deviations caused by manufacturing variations, environmental factors, and other influences. Here's a general guide to capacitance pressure sensor calibration:

1. Gather Necessary Equipment:

- Calibrated pressure reference standards with known and traceable values.

- Calibration software or hardware if applicable.

- Proper safety equipment and tools.

2. Establish Calibration Environment:

- Ensure the calibration environment matches or closely simulates the actual operating conditions of the sensor, including temperature and pressure.

3. Zero Calibration (if applicable):

- If your sensor has a zero calibration adjustment, set it to correspond to zero pressure or atmospheric pressure.

4. Calibration Procedure:

- Apply a series of known pressure values to the sensor using the reference standards.

- Record the output readings from the sensor for each applied pressure.

5. Plot Calibration Curve:

- Plot a calibration curve by graphing the recorded sensor readings against the known reference pressures.

6. Determine Calibration Equation:

- Analyze the calibration curve to determine the mathematical equation that relates sensor output (voltage, current, etc.) to actual pressure values. This equation can be linear or nonlinear.

7. Adjust Calibration Settings:

- If your sensor allows, adjust the calibration settings based on the determined equation. This might involve modifying calibration coefficients or programming the sensor's electronics.

8. Verify Calibration:

- Apply a few more pressure values within the range to verify that the sensor's output matches the expected values based on the calibration equation.

9. Document Calibration:

- Maintain thorough records of the calibration process, including calibration coefficients, calibration date, and any adjustments made.

10. Recalibration Schedule:

- Establish a regular recalibration schedule based on your sensor's specifications and your application's needs. Calibration drift over time might necessitate periodic recalibration.

11. Traceability and Certifications:

- Ensure that your calibration standards have traceable certifications, which provide confidence in the accuracy of your calibration process.

It's important to note that some capacitance pressure sensors might have specific calibration procedures or requirements provided by the manufacturer. Always refer to the sensor's user manual and the manufacturer's guidelines for calibration procedures, as they can vary based on the sensor's design and technology.

If you're uncertain about performing the calibration yourself, consider seeking assistance from calibration professionals or calibration laboratories that have the necessary equipment and expertise to ensure accurate results.

Capacitance Pressure Sensor Accuracy

The accuracy of a capacitance pressure sensor refers to how closely its measured pressure values correspond to the actual, true pressure. It's a crucial factor in ensuring reliable and trustworthy measurements for various applications. Capacitance pressure sensor accuracy is typically expressed as a percentage of the full-scale output (%FSO) or as an absolute pressure value. Here's how accuracy is assessed and the factors that influence it:

Assessing Accuracy:

- Specified Accuracy: Manufacturers provide accuracy specifications in datasheets. It's essential to understand how accuracy is defined (e.g., %FSO, absolute value) and the conditions under which the accuracy is guaranteed (e.g., temperature range, pressure range).

- Calibration: Proper calibration aligns the sensor's output with reference standards, ensuring that the sensor's readings are accurate within the specified range.

- Testing: Conduct comparison tests using reference standards to verify the sensor's accuracy across its intended pressure range.

Factors Influencing Accuracy:

- Sensor Quality: High-quality sensors with tighter manufacturing tolerances tend to offer better accuracy.

- Environmental Conditions: Temperature fluctuations, humidity, and other environmental factors can impact accuracy. Some sensors might have temperature compensation mechanisms to mitigate these effects.

- Calibration Quality: The precision and quality of the calibration process greatly influence accuracy. Regular recalibration is important to maintain accuracy over time.

- Sensor Design: The sensor's mechanical and electrical design, diaphragm quality, electrode alignment, and insulation materials can affect accuracy.

- Electrical Noise: External electromagnetic interference and electrical noise can lead to inaccuracies in the sensor's output.

- Electrical Circuitry: The accuracy of the signal conditioning and analog-to-digital conversion circuitry used with the sensor can impact overall accuracy.

- Pressure Range: Some sensors might exhibit different accuracy levels across different pressure ranges within their specification.

- Linearity: The linearity of the sensor's output response to pressure variations affects accuracy. Deviations from a linear response can introduce inaccuracies.

Selecting an Accurate Sensor:

- Read Datasheets: Thoroughly review the manufacturer's datasheets for accuracy specifications and other relevant information.

- Consider Application Requirements: Choose a sensor with accuracy that meets your application's demands. Over-specifying accuracy might lead to unnecessary costs.

- Environmental Compatibility: Ensure the sensor's specified accuracy matches your application's operating conditions, including temperature and pressure ranges.

- Calibration: Understand whether the sensor requires calibration and how often. This can impact ongoing accuracy.

- Calibration Services: If precision is paramount, consider utilizing professional calibration services for accurate and traceable results.

It's important to note that actual accuracy in a real-world application can be influenced by various factors, so it's advisable to conduct thorough testing and verification specific to your use case to ensure the sensor meets your accuracy requirements.

Fig 11. Sensor working principle

What are the advantages and disadvantages of Capacitance Pressure Sensors?

Capacitance pressure sensors offer both advantages and disadvantages, which should be carefully considered when selecting them for specific applications. Here's an overview of the pros and cons of capacitance pressure sensors:

Advantages:

- High Accuracy: Capacitance pressure sensors can provide high levels of accuracy and precision in pressure measurements, making them suitable for applications that require precise readings.

- Wide Pressure Range: These sensors can cover a wide range of pressure values, from low to high pressures, depending on the sensor's design and specifications.

- Non-Intrusive: Capacitance sensors do not require direct physical contact with the pressure source, which can be beneficial for sensitive or delicate substances.

- No Moving Parts: Many capacitance pressure sensors do not have moving parts, which reduces wear and tear, leading to longer sensor lifespan and improved reliability.

- High Sensitivity: Capacitance changes are highly sensitive to small pressure variations, enabling the detection of even minor pressure changes.

- Corrosion Resistance: Some capacitance pressure sensors are designed with corrosion-resistant materials, making them suitable for harsh or corrosive environments.

- Fast Response Time: Capacitance sensors can provide rapid response times, making them suitable for applications requiring real-time pressure monitoring and control.

- Compact Size: Capacitance sensors can be designed to be compact and lightweight, making them easier to integrate into various systems and applications.

Disadvantages:

- Calibration Requirement: Many capacitance pressure sensors require calibration to ensure accurate measurements. Calibration can be complex and time-consuming.

- Temperature Effects: Temperature changes can affect the dielectric properties of materials, leading to variations in capacitance and affecting accuracy.

- Environmental Factors: Environmental conditions such as humidity and electromagnetic interference can impact sensor performance and require proper control.

- Complex Design: The design of capacitance pressure sensors can be intricate, potentially leading to manufacturing challenges and increased costs.

- Electromagnetic Interference: External electromagnetic fields can interfere with sensor readings, requiring proper shielding and filtering.

- Electrical Noise Sensitivity: Capacitance sensors can be sensitive to electrical noise, which might require additional measures to mitigate interference.

- Limited Pressure Range for Some Types: Certain types of capacitance pressure sensors might have limitations in terms of the pressure range they can effectively cover.

- Specific Dielectric Properties Required: The material properties of the substance being measured need to influence capacitance to obtain accurate readings.

When considering the use of capacitance pressure sensors, it's crucial to evaluate their advantages and disadvantages within the context of your specific application. Consider factors such as accuracy requirements, environmental conditions, installation challenges, and budget constraints to determine whether capacitance pressure sensors are the best choice for your needs.

How can choose the proper Capacitance Pressure Sensor?

Choosing the right capacitance pressure sensor involves a thoughtful evaluation of your application's requirements, performance specifications, and environmental conditions. Here's a step-by-step guide to help you select the proper capacitance pressure sensor for your specific needs:

- Identify Application Requirements:

- Determine the pressure range you need to measure. Choose a sensor that covers this range effectively.

- Define the desired accuracy of pressure measurements. Consider how precise the readings need to be for your application.

- Understand Environmental Conditions:

- Assess the temperature range, humidity levels, and potential exposure to chemicals or corrosive substances in the sensor's operating environment.

- Choose a sensor that can withstand these conditions without compromising performance.

- Sensor Type Selection:

- Consider the type of pressure measurement you need: absolute, differential, or gauge pressure.

- Choose a sensor type that aligns with your application's pressure reference point.

- Sensor Material Compatibility:

- Ensure that the sensor's materials are compatible with the media (liquid, gas) that will be in contact with the diaphragm or sensing element.

- Calibration Requirements:

- Determine if the sensor requires calibration to ensure accurate readings.

- Consider whether you have the necessary equipment and expertise to perform calibration.

- Response Time:

- Evaluate the required response time for your application. Some applications demand rapid real-time pressure monitoring, while others allow for slower response times.

- Output and Signal Processing:

- Determine the type of output signal you need: analog (voltage or current) or digital (serial communication).

- Ensure that the sensor's output is compatible with your data acquisition or control system.

- Mechanical Considerations:

- Assess the available space for sensor installation and the physical dimensions of the sensor.

- Consider mounting options, such as threaded connections or flanges, to ensure proper integration.

- Budget and Cost Considerations:

- Determine your budget for the sensor and related equipment, including any additional components required for integration.

- Manufacturer Reputation and Support:

- Research reputable manufacturers known for producing reliable and high-quality sensors.

- Check for available technical support, documentation, and warranties.

- Read Reviews and Recommendations:

- Look for customer reviews and recommendations from professionals who have used similar sensors in your industry.

- Sample Testing (if possible):

- If feasible, test a sample of the sensor in your specific application to ensure it meets your performance expectations.

- Scalability and Future Needs:

- Consider whether the chosen sensor can accommodate potential changes or expansions in your application.

- Consult Experts:

- If you're uncertain about the best sensor for your application, seek advice from experts or engineers who specialize in pressure sensing.

By systematically evaluating these factors and conducting thorough research, you can confidently choose the proper capacitance pressure sensor that meets your application's requirements while ensuring accuracy, reliability, and optimal performance.

Fig 12. Capacitance of a load mode capacitive sensor

What are the top brands of Capacitance Pressure Sensors?

As of my last knowledge update in September 2021, there are several well-known brands that manufacture high-quality capacitance pressure sensors. Keep in mind that the availability and reputation of brands might change over time. Here are some top brands known for producing capacitance pressure sensors:

- Honeywell: Honeywell is a globally recognized brand in sensors and industrial automation. They offer a range of pressure sensors, including capacitance-based options.

- Sensata Technologies: Sensata is known for its sensors and controls for a wide range of applications, including automotive, industrial, and aerospace. They offer capacitive pressure sensors.

- WIKA: WIKA is a manufacturer of industrial measurement technology, including pressure sensors. They provide various types of pressure sensors, including capacitive options.

- Kavlico: Kavlico, a brand of Sensata Technologies, specializes in pressure and position sensors. They offer a variety of pressure sensor solutions, including capacitance-based models.

- Emerson: Emerson offers a range of sensing solutions for industrial applications. Their Rosemount brand includes pressure sensors, and they might offer capacitance-based options.

- Balluff: Balluff is known for industrial automation solutions and sensors. They offer capacitance-based pressure sensors for various applications.

- Viatran: Viatran specializes in pressure and level measurement solutions. They provide a range of pressure sensors, and they might have capacitance-based options.

- Omega Engineering: Omega Engineering offers a wide variety of sensors and instrumentation for industrial applications. They might offer capacitance pressure sensors as part of their product lineup.

- ifm electronic: ifm electronic produces sensors and control systems for industrial automation. They might offer capacitance pressure sensors for specific applications.

- Meggitt Sensing Systems: Meggitt offers sensing solutions for various industries, including aerospace, defense, and industrial. They might have capacitance pressure sensors in their product range.

Please note that the availability of specific brands and models might change, and new brands might emerge in the market. Before making a purchase, it's essential to research the latest information, read reviews, and check the manufacturer's specifications to ensure that the capacitance pressure sensor meets your application's requirements.

Conclusion

Capacitance sensors are versatile devices that utilize changes in capacitance to measure various parameters such as pressure, proximity, humidity, and more. Their non-contact nature, high sensitivity, and wide range of applications make them valuable tools across industries. From touchscreens to industrial automation, these sensors play a crucial role in enhancing user experiences, improving efficiency, and ensuring accurate measurements.

When choosing a capacitance sensor, it's essential to consider factors such as the measurement parameter, accuracy requirements, environmental conditions, and sensor type. Thorough research, consultation with experts, and testing in relevant scenarios can help you make an informed decision.

However, keep in mind that while capacitance sensors offer numerous advantages like non-intrusiveness and high sensitivity, they also come with challenges such as calibration needs, sensitivity to environmental factors, and potential complexity in design. Mitigating these challenges requires careful calibration, proper maintenance, and integration of suitable signal processing techniques.

As technology continues to advance, capacitance sensors are likely to become even more refined and adaptable, further expanding their applications and making them an integral part of modern measurement and automation systems. Whether in consumer electronics, industrial processes, or scientific research, capacitance sensors contribute to safer, more efficient, and more accurate systems, enriching our understanding of the world around us.

To recap

1. What is a capacitance pressure sensor?

A capacitance pressure sensor is a device that measures pressure changes by detecting variations in capacitance, the ability of a capacitor to store an electric charge. It uses a diaphragm exposed to pressure, which alters the capacitance between electrodes, translating pressure into an electrical signal.

2. How does a capacitance pressure sensor work?

Capacitance pressure sensors work by measuring the change in capacitance caused by the deformation of a diaphragm in response to pressure. As pressure changes, the diaphragm moves, altering the distance between electrodes and hence the capacitance. This change is converted into an output signal proportional to the applied pressure.

3. What are the advantages of capacitance pressure sensors?

Advantages include high accuracy, sensitivity to small pressure changes, non-intrusive measurement, wide pressure range, high reliability (few moving parts), and suitability for various media (liquids, gases).

4. What types of pressure can capacitance pressure sensors measure?

Capacitance pressure sensors can measure absolute pressure, gauge pressure, and differential pressure. The specific type depends on the sensor's design and application.

5. Do capacitance pressure sensors require calibration?

Many capacitance pressure sensors require calibration to ensure accurate readings. Calibration aligns the sensor's output with known pressure values and compensates for variations.

6. What factors affect the accuracy of capacitance pressure sensors?

Accuracy can be influenced by temperature changes, manufacturing variations, environmental conditions, sensor design, and calibration quality.

7. How are capacitance pressure sensors installed?

Install the sensor in a suitable location, ensuring proper alignment with the pressure source. Connect it to a power supply and signal processing circuitry. Consider factors like environmental conditions and mechanical protection.

8. Can capacitance pressure sensors measure other parameters besides pressure?

While primarily used for pressure measurement, capacitance sensors can also measure other parameters like liquid level, density, and humidity in some cases.

9. What are the common applications of capacitance pressure sensors?

Applications include industrial process control, automotive systems, medical devices, aerospace, HVAC systems, and more, where accurate pressure monitoring is crucial.

10. How do I troubleshoot issues with capacitance pressure sensors?

If you encounter problems, check sensor connections, calibration status, environmental factors, and potential electrical interference. Consult the manufacturer's troubleshooting guide if needed.

References

https://vitrek.com/capacitance-sensors-three-things/

https://www.motioncontroltips.com/what-are-capacitive-proximity-sensors/

https://byjus.com/physics/capacitive-sensors/

https://realpars.com/capacitive-sensor/

https://www.embedded.com/getting-in-touch-with-capacitance-sensor-algorithms/

https://www.ifm.com/us/en/us/overview/capacitive/technology-overview/technology-overview

https://www.synaptics.com/technology/touch-sensing

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025