Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction

Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyrocketing energy bills again. What if your water system could adapt seamlessly to your needs, saving you money and conserving energy all at once? Welcome to the future of water pressure management—energy-efficient booster pumps.

With rising energy costs and increasing environmental concerns, traditional water pumps are becoming outdated. They waste energy, cost more to maintain, and struggle to meet modern demands. That’s where energy-efficient booster pumps come in—an innovative solution designed to deliver consistent water pressure, lower electricity consumption, and longer-lasting performance.

In this guide, we’ll explore why these pumps are transforming homes, businesses, and industries worldwide. From choosing the right model to tips on maximizing performance, you’ll discover how to enhance your water system while reducing your carbon footprint. Get ready to upgrade your water system and your peace of mind!

2. What Are Energy-Efficient Booster Pumps?

Energy-efficient booster pumps are an advanced solution designed to provide consistent water pressure and flow while minimizing energy consumption. Unlike traditional booster pumps that operate at a fixed speed regardless of demand, energy-efficient pumps utilize modern technologies to adapt their performance in real-time, ensuring that water is supplied as efficiently as possible.

Key Features of Energy-Efficient Booster Pumps

- Variable Speed Control:

These pumps are equipped with Variable Frequency Drives (VFDs) that allow them to adjust motor speed based on water demand. This ensures precise control over water flow and pressure while reducing unnecessary energy use.

- Advanced Sensors:

Sensors monitor real-time system conditions, such as water pressure and flow rates, allowing the pump to operate only when needed and at the appropriate speed.

- High-Efficiency Motors:

Many energy-efficient booster pumps use premium-grade motors with high energy efficiency ratings, reducing power consumption without compromising performance.

- Smart Automation:

Built-in controllers enable automated start-stop functions, energy-saving modes, and protective mechanisms to ensure long-term reliability.

How They Work

Energy-efficient booster pumps regulate water flow and pressure by continuously analyzing system requirements. For instance, during peak usage hours when multiple taps are open, the pump increases speed to maintain consistent pressure. Conversely, during periods of low demand, the pump slows down or temporarily shuts off to save energy. This dynamic adjustment minimizes energy wastage and wear on the system.

Applications of Energy-Efficient Booster Pumps

- Residential Use:

Ideal for homes, villas, and apartment buildings where consistent water pressure is needed, especially during peak usage times.

- Commercial Settings:

Frequently used in hotels, offices, and retail complexes to ensure reliable water pressure across multiple outlets.

- Agricultural Irrigation:

Suitable for irrigation systems requiring precise water flow and pressure to optimize crop yield.

- Industrial Operations:

Used in factories and processing plants to meet water supply demands efficiently.

Why They’re Essential

Energy-efficient booster pumps not only reduce energy costs but also contribute to environmental sustainability by minimizing the carbon footprint of water systems. Additionally, their ability to operate quietly and reliably makes them a superior choice for residential and commercial users alike.

By integrating these cutting-edge pumps into your water system, you can achieve significant energy savings, reduce wear and tear on equipment, and enjoy consistent water pressure that adapts to your unique needs.

3. Why Choose Variable Speed Booster Pumps?

Variable speed booster pumps, powered by Variable Frequency Drives (VFDs), are rapidly becoming the preferred choice for water pressure management in homes, commercial buildings, and industrial setups. Unlike traditional fixed frequency pumps that run at a constant speed, variable speed pumps adapt to real-time water demand, offering unparalleled efficiency, comfort, and performance.

Fig 2. A variable speed booster pump

What Makes Variable Speed Pumps Different?

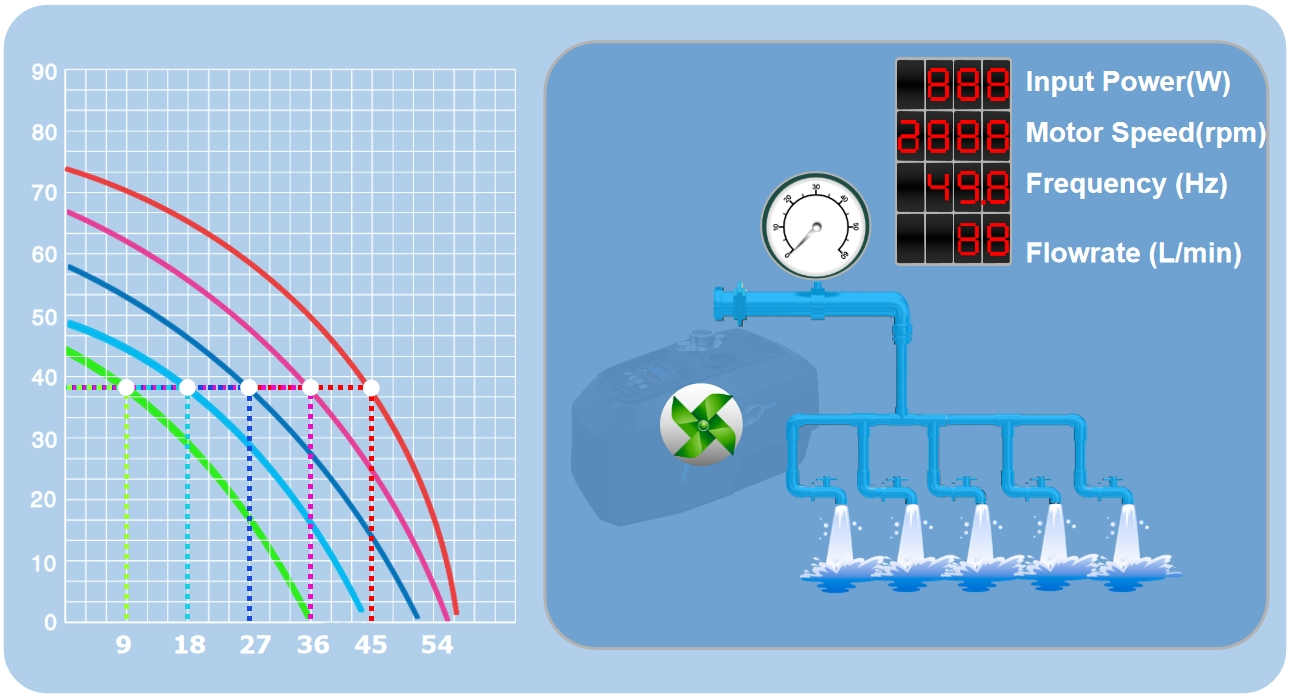

A variable speed pump integrates advanced technology to dynamically adjust its motor speed based on system requirements. Equipped with smart sensors, controllers, and energy-efficient motors, these pumps ensure water pressure remains consistent, regardless of fluctuations in demand.

Key Advantages Over Fixed Frequency Pumps

- Constant Water Pressure for Enhanced Comfort

- One of the standout benefits of variable speed pumps is their ability to maintain steady water pressure, even during peak usage periods.

- In traditional systems, water pressure can drop significantly when multiple taps are running. Variable speed pumps solve this issue by continuously monitoring system conditions and adjusting motor speed to ensure consistent pressure.

- Example: A pump like the HYDROBOX900 can be set to deliver a default pressure (e.g., 3 bar) and ensure uniform pressure across all outlets, whether you’re taking a shower, washing dishes, or watering the garden simultaneously.

- Significant Energy Savings

- Variable speed pumps only consume the energy necessary for the task at hand. During low-demand periods, the pump reduces its speed, consuming far less energy than fixed frequency pumps, which operate at maximum speed regardless of need.

- This not only cuts electricity bills but also reduces the pump's overall carbon footprint.

- Example: The HYDROBOX900 boasts a permanent magnet motor with 85% efficiency, reducing power consumption by 30%-60% compared to traditional pumps.

- Soft Start to Protect Equipment and Prevent Pipe Bursts

- Unlike fixed frequency pumps, which can cause a sudden pressure surge during startup, variable speed pumps initiate operation gradually. This soft start reduces the risk of damage to pipes and connected appliances, ensuring longer equipment lifespan and fewer maintenance issues.

- Example: By eliminating pressure spikes, a variable speed pump minimizes the likelihood of pipe leaks and system wear.

- Noise Reduction for a Quieter Environment

- Fixed frequency pumps often run at high speeds, generating significant noise. Variable speed pumps operate at lower speeds during non-peak hours, drastically reducing noise levels.

- Example: The HYDROBOX900 features a sound-proof inner box that ensures quiet operation, making it perfect for indoor installations in homes or offices.

- Improved System Longevity

- The ability to adjust motor speed according to demand reduces mechanical stress and wear, extending the pump’s lifespan and lowering long-term maintenance costs.

A Real-World Example: The HYDROBOX900

The HYDROBOX900 demonstrates why variable speed pumps are ideal for domestic water pressure systems. With its high-precision sensors, smart control panel, and energy-efficient motor, it delivers a reliable, quiet, and environmentally friendly water supply solution. Advanced features like automatic start-stop functions and real-time pressure adjustment make it a standout choice for homeowners seeking comfort and cost savings.

Choosing a variable speed booster pump with a frequency converter is a smart decision for anyone looking to balance performance, efficiency, and sustainability. By providing constant water pressure, saving energy, and reducing noise, these pumps offer a modern solution that outperforms traditional fixed frequency models. Whether for home, agriculture, or commercial applications, variable speed pumps are a long-term investment in comfort, cost savings, and environmental responsibility.

4. Key Factors to Consider When Selecting a Booster Pump

Choosing the right booster pump is crucial to achieving optimal performance, energy efficiency, and long-term reliability. With a variety of models available, it’s essential to understand the key factors that should guide your decision.

1. Proper Sizing

- Why It Matters: The size of the pump directly affects its efficiency and ability to meet your water pressure and flow needs. An undersized pump will struggle to deliver sufficient pressure, while an oversized pump wastes energy and increases operating costs.

- How to Size Correctly:

- Calculate the Total Dynamic Head (TDH), which includes static height, friction losses in pipes, and pressure requirements.

- Determine the flow rate needed for your application, measured in gallons per minute (GPM) or liters per second (L/s).

- Pro Tip: Use pump sizing tools or consult a professional to ensure the selected pump aligns with your specific requirements.

2. Pump Type

- Variable Speed Booster Pumps: Ideal for applications with fluctuating demand, offering energy efficiency and consistent water pressure.

- Single-Stage Pumps: Suitable for applications requiring moderate pressure and flow rates, such as small residential systems.

- Multi-Stage Pumps: Designed for high-pressure applications, such as large homes, villas, or commercial setups.

- Hybrid Options: Pumps like the HYDROBOX900 combine variable speed control with high efficiency, making them versatile for various settings.

3. Material Durability

- Why It Matters: The materials used in a pump determine its resistance to wear, corrosion, and environmental conditions.

- Key Considerations:

- Corrosion Resistance: For areas with hard or acidic water, choose pumps with stainless steel or high-grade polymer components.

- Temperature Tolerance: Ensure the pump materials can handle the temperature range of your water source (e.g., Stream EA pumps handle fluid temperatures from 2°C to 110°C).

4. System Compatibility

- Ensure the pump can integrate seamlessly with your existing system.

- Key Parameters to Check:

- Total Dynamic Head (TDH) compatibility.

- Flow rate requirements of your home or application.

- Voltage and frequency compatibility with the power supply.

5. Advanced Features

- Look for pumps with modern features to enhance convenience and efficiency:

- Variable Frequency Drives (VFDs) for energy savings and demand-based operation.

- Smart Sensors for real-time monitoring of pressure and flow.

- Automated Start-Stop Functions to reduce wear and extend pump life.

6. Noise Levels

- Why It Matters: Quiet operation is especially important for indoor installations in homes or offices.

- What to Look For:

- Pumps with soundproof casings or low-noise motors (e.g., HYDROBOX900 features noise levels ≤42 dB).

7. Maintenance Requirements

- Ease of Maintenance: Choose a pump with accessible components for cleaning and repair.

- Long-Term Durability: Opt for models with high-quality seals and bearings to reduce the frequency of maintenance.

8. Energy Efficiency Ratings

- Check for pumps with high energy efficiency ratings (e.g., EEI ≤ 0.23 for ERP compliance) to ensure long-term savings on electricity bills.

Selecting the right booster pump requires careful evaluation of your specific needs, system requirements, and long-term goals. Whether you’re optimizing water pressure for a single home or managing complex systems for commercial use, focusing on the right size, type, and features will ensure maximum efficiency and reliability. Advanced options like the HYDROBOX900 and Stream EA Series demonstrate how innovative technologies can simplify the decision-making process, delivering the perfect balance of performance, energy savings, and comfort.

5. Benefits of Energy-Efficient Booster Pumps

Energy-efficient booster pumps offer numerous advantages over traditional models, making them a smart investment for homeowners, businesses, and industries alike. By combining advanced technology with sustainable performance, these pumps provide both immediate and long-term benefits that go beyond just water pressure management.

1. Lower Operating Costs

- Energy Savings: Variable speed booster pumps, equipped with VFDs (Variable Frequency Drives), adjust motor speed based on water demand. This reduces electricity consumption significantly compared to fixed frequency pumps that run at constant speed.

- Cost Efficiency: By consuming only the energy needed, these pumps can lower electricity bills by 30%-60%, especially in households or businesses with fluctuating water usage.

- Example: The HYDROBOX900 uses a permanent magnet motor with 85% efficiency, ensuring both energy conservation and cost savings.

2. Improved System Longevity

- Reduced Wear and Tear: Traditional pumps often experience mechanical stress due to constant operation at full speed. Energy-efficient pumps, with their adaptive speed control, minimize strain on components like seals, impellers, and motors.

- Soft Start and Stop: The gradual ramp-up and down of speed during startup and shutdown protect pipes and reduce pressure shocks, preventing leaks and extending system life.

- Lower Maintenance Costs: With less wear, the need for frequent repairs and replacements is reduced, further saving costs over time.

3. Consistent and Reliable Water Pressure

- Enhanced Comfort: One of the standout features of energy-efficient booster pumps is their ability to maintain steady water pressure, even during high-demand periods. Whether multiple taps are running or appliances like washing machines and dishwashers are in use simultaneously, these pumps ensure consistent flow without noticeable drops in pressure.

- Example: A pump like the HYDROBOX900 delivers stable pressure at every outlet, even during peak usage times.

4. Environmentally Friendly Performance

- Reduced Carbon Footprint: By consuming less electricity, energy-efficient pumps lower greenhouse gas emissions, contributing to global sustainability goals.

- Compliance with Standards: Many of these pumps meet or exceed energy efficiency regulations, such as the ERP standard (e.g., Stream EA Series with EEI ≤ 0.23), ensuring eco-friendly operation.

5. Noise Reduction for Enhanced Comfort

- Quieter Operation: Unlike traditional pumps that run loudly at full speed, energy-efficient models operate at reduced speeds during low-demand periods, minimizing noise levels.

- Ideal for Indoor Use: Pumps like the HYDROBOX900 feature soundproof designs, making them perfect for residential and office installations where quiet operation is critical.

- Adaptability to Diverse Applications

- Energy-efficient booster pumps are versatile, making them suitable for various scenarios:

- Residential: Ensures steady pressure for daily household tasks like showers, dishwashing, and laundry.

- Commercial: Supports consistent water supply in offices, hotels, and retail spaces.

- Industrial: Optimizes water usage in factories and production facilities.

- Agricultural: Provides precise water flow and pressure for irrigation systems, promoting better crop yields.

Why Energy-Efficient Pumps Are the Future

Energy-efficient booster pumps combine cutting-edge technology, sustainable operation, and user convenience to meet the evolving needs of modern water systems. They offer an ideal balance between performance, cost savings, and environmental responsibility, making them a must-have for anyone seeking reliable and efficient water pressure solutions.

By upgrading to an energy-efficient model, you not only enhance the comfort and reliability of your water system but also contribute to a greener future while saving on energy costs. Whether for homes, businesses, or large-scale operations, these pumps are a smart investment in efficiency and sustainability.

6. Common Issues and Solutions in Booster Pumps

While energy-efficient booster pumps offer exceptional performance and reliability, they can occasionally face operational issues, especially when improperly installed, maintained, or used under specific conditions. Understanding these common problems and their solutions can help you avoid costly repairs and ensure the long-term efficiency of your pump.

1. Common Issues in Booster Pumps

- Cavitation Due to Low Inlet Pressure:

- Cause: Cavitation occurs when the inlet water pressure is too low, leading to the formation of vapor bubbles that collapse inside the pump. This damages the impellers and reduces pump performance.

- Impact: Decreased efficiency, overheating, and potential impeller deformation.

- Pump Cycling or Non-Stop Operation:

- Cause: Excessively high pressure settings or small leaks in the outlet pipeline can prevent the pump from shutting down when water demand stops.

- Impact: Increased energy consumption, wear on motor components, and potential overheating.

- Overheating:

- Cause: Continuous operation without adequate water flow can lead to overheating, especially if the pump lacks proper temperature monitoring.

- Impact: Damage to seals, deformation of pump components, and system failure.

2. Solutions and Preventive Measures

- Flow Monitoring with Real-Time Sensors:

- Solution: Install flow switches to detect water flow at the outlet. If no flow is detected, the system can automatically shut down the pump to prevent unnecessary operation.

- Example: The HYDROBOX900 features a built-in flow switch that halts pump operation after 10 seconds of no flow, protecting the system from damage.

- Temperature Control for Overheat Protection:

- Solution: Equip the pump with temperature sensors to monitor pump body temperature. If overheating occurs, the pump stops automatically and displays an alarm, ensuring safety.

- Example: HYDROBOX900 includes a temperature sensor that triggers shutdown if the pump body temperature exceeds preset limits, requiring manual reset for safe operation.

- Adjusting Pressure Settings:

- Solution: Avoid setting excessively high pressures unless absolutely necessary. Optimize settings to meet your specific water demand without overloading the pump.

- Tip: Work with a professional to calibrate the pump for your system's requirements.

- Regular Maintenance to Address Leaks:

- Solution: Inspect pipelines and connections for leaks, particularly at the outlet. Small leaks can prevent the pump from shutting down correctly.

- Proactive Step: Use high-quality seals and ensure proper installation to minimize potential leakage points.

3. Upgrades and Protective Strategies

Modern energy-efficient pumps incorporate advanced features to mitigate common issues and enhance reliability:

- Flow Switches: Real-time detection of water flow ensures the pump operates only when necessary.

- Temperature Sensors: Provide analog signals to monitor pump body heat and prevent overheating.

- Smart Control Panels: Upgraded software enhances performance and ensures smooth operation.

4. Real-World Example: HYDROBOX900

The HYDROBOX900 has been upgraded to address these common issues effectively:

- Flow Switch Shutdown: Automatically stops the pump when no water flow is detected, preventing cycling and overheating.

- Temperature Sensor Shutdown: Protects against cavitation by halting the pump when the body temperature exceeds safe limits, displaying a high-temperature alarm for manual reset.

Understanding and addressing common booster pump issues ensures smooth operation, energy efficiency, and long-term system reliability. With features like real-time monitoring, automatic shutdown strategies, and advanced control systems, energy-efficient pumps like the HYDROBOX900 are built to tackle these challenges effectively.

By proactively addressing these issues through proper installation, regular maintenance, and advanced technologies, you can maximize the performance and lifespan of your booster pump, ensuring consistent water pressure and peace of mind.

7. Tips for Maximizing Performance and Efficiency

Energy-efficient booster pumps are designed to deliver optimal performance, but achieving their full potential requires careful installation, regular maintenance, and smart usage. Implement these practical tips to maximize your pump’s efficiency, reduce energy consumption, and extend its lifespan.

1. Ensure Proper Installation

- Accurate Sizing:

- Ensure the pump is correctly sized for your system's Total Dynamic Head (TDH) and flow rate requirements.

- An oversized or undersized pump can lead to inefficiency, higher energy costs, or inadequate pressure.

- Professional Setup:

- Have a professional installer calibrate the pump to your system’s specifications. Proper alignment, secure fittings, and leak-free connections are essential for efficient operation.

- Minimize Friction Losses:

- Use the correct pipe diameter and minimize bends and obstructions in the pipeline to reduce resistance and improve water flow.

2. Leverage Advanced Features

- Variable Speed Control:

- Take advantage of Variable Frequency Drives (VFDs) to adjust the pump’s motor speed based on real-time water demand.

- Example: The HYDROBOX900 dynamically regulates motor speed to maintain constant pressure, reducing energy consumption during low-demand periods.

- Smart Sensors and Automation:

- Use pumps with built-in sensors for pressure and flow monitoring. Automated start-stop features help avoid unnecessary operation and save energy.

3. Perform Regular Maintenance

- Clean and Inspect Components:

- Regularly check for debris in filters and clean them to avoid clogs that could strain the pump.

- Inspect for Leaks:

- Check all connections, pipelines, and seals for signs of leakage and repair them promptly.

- Monitor Impeller Condition:

- Inspect the impeller for wear or damage, as it directly impacts the pump's efficiency and water pressure delivery.

- Lubricate Moving Parts:

- Ensure all mechanical components are well-lubricated to prevent friction and wear.

4. Optimize Operating Conditions

- Set Appropriate Pressure Levels:

- Avoid excessively high pressure settings to reduce strain on the pump and prevent overheating or cycling.

- Example: Set the HYDROBOX900 to a default pressure of 3 bar (or customize it as needed) for balanced performance.

- Monitor Inlet Water Supply:

- Ensure consistent and adequate water supply to prevent cavitation, which can damage pump components.

5. Upgrade to Modern Technology

- IoT Integration:

- Consider upgrading to pumps with IoT-enabled systems for real-time monitoring and control. These systems provide insights into energy consumption, flow rates, and system health.

- Noise Reduction Features:

- For indoor installations, opt for pumps with soundproof casings or low-noise motors (e.g., HYDROBOX900 with ≤42 dB noise levels).

6. Use Energy-Saving Strategies

- Adjust for Peak and Off-Peak Usage:

- Reduce energy consumption by operating the pump at lower speeds during periods of low demand.

- Incorporate Renewable Energy:

- Pair your booster pump with renewable energy sources, such as solar power, to further enhance sustainability.

Maximizing the performance and efficiency of your energy-efficient booster pump requires a combination of proper installation, regular maintenance, and the use of advanced features. Pumps like the HYDROBOX900 demonstrate how intelligent design and modern technology can simplify these tasks, providing consistent water pressure while reducing energy consumption.

By following these tips, you can ensure that your booster pump operates at peak efficiency, delivering reliable performance, minimizing operating costs, and extending the life of your system—all while contributing to a more sustainable and comfortable living or working environment.

8. Energy Optimization Strategies

Maximizing the efficiency of energy-efficient booster pumps requires not only advanced technology but also smart system design and usage strategies. By implementing these energy optimization techniques, you can reduce power consumption, enhance performance, and extend the lifespan of your booster pump system.

1. Smart System Design

- Optimize Pipe Diameters:

- Ensure the pipe diameter matches the pump’s output to minimize friction losses and pressure drops.

- Wider pipes can reduce resistance, allowing water to flow more efficiently, especially in large systems.

- Minimize Pipe Bends and Lengths:

- Design piping systems with as few bends and short lengths as possible to prevent unnecessary energy loss.

2. Leverage Variable Frequency Drives (VFDs)

- Dynamic Speed Adjustment:

- VFDs adjust the pump’s motor speed in real-time, matching performance to actual water demand. This ensures the pump operates only as fast as needed, reducing energy waste.

- Example: During low water demand periods, the HYDROBOX900 reduces speed to conserve energy while maintaining adequate pressure.

- Avoid Overloading:

- Set appropriate maximum and minimum speeds for your VFD pump to prevent overloading or underperformance.

3. Real-Time Monitoring and Automation

- Smart Sensors:

- Use sensors to monitor water flow, pressure, and pump performance. These sensors enable automated adjustments, ensuring the system operates within its most efficient range.

- IoT Integration:

- Integrate Internet of Things (IoT) technology to track energy consumption and system health remotely. IoT-enabled pumps allow for proactive adjustments and maintenance to optimize performance.

4. Implement Renewable Energy Sources

- Solar-Powered Pumps:

- Pair your booster pump with solar panels for a sustainable energy solution. This not only reduces operating costs but also decreases reliance on non-renewable energy sources.

- Hybrid Systems:

- Combine traditional and renewable energy systems for reliable and eco-friendly operation, particularly in areas with inconsistent grid power.

5. Regular Maintenance and Calibration

- Clean Filters and Inspect Components:

- Clogged filters or worn-out components can strain the pump, leading to higher energy consumption. Regular cleaning and timely replacement ensure smooth operation.

- Calibrate System Settings:

- Regularly check and adjust system pressure, flow rates, and VFD settings to ensure optimal energy efficiency.

6. Schedule Off-Peak Operation

- Lower Costs with Off-Peak Scheduling:

- Where applicable, schedule pump operation during off-peak electricity hours to reduce energy costs.

- Demand-Based Scheduling:

- Use programmable controllers to operate the pump only when water demand is high, avoiding unnecessary energy usage during low-demand periods.

7. Choose High-Efficiency Equipment

- Energy-Efficient Motors:

- Select pumps with high-efficiency motors, such as those meeting ERP standards (e.g., Stream EA Series with EEI ≤ 0.23).

- Smart Models:

- Invest in pumps with automated features like the HYDROBOX900, which uses high-precision sensors and a permanent magnet motor for optimal energy usage.

Energy optimization is not just about choosing the right booster pump; it’s about designing and managing the entire system to work as efficiently as possible. By implementing strategies such as smart system design, leveraging advanced technologies like VFDs and IoT, and integrating renewable energy sources, you can significantly reduce energy consumption and operational costs.

Energy-efficient booster pumps, such as the HYDROBOX900 and Stream EA Series, are designed to make energy optimization easier with built-in smart features and sustainable performance. By adopting these strategies, you’ll not only enhance your system’s efficiency but also contribute to a greener, more cost-effective water supply solution.

9. Cost-Benefit Analysis of Energy-Efficient Pumps

Investing in energy-efficient booster pumps can initially seem like a significant expense, but the long-term benefits far outweigh the costs. Understanding the financial implications and performance advantages helps justify the decision to upgrade to these advanced systems. Here’s a comprehensive breakdown of the costs and benefits:

1. Initial Investment

- Cost of Energy-Efficient Pumps:

- Energy-efficient booster pumps, such as variable speed models, typically have higher upfront costs compared to traditional fixed frequency pumps. This is due to the integration of advanced features like Variable Frequency Drives (VFDs), smart sensors, and high-efficiency motors.

- Example:

- A basic fixed frequency pump may cost less initially, but a variable speed pump like the HYDROBOX900 includes additional capabilities, offering better value over time.

- Installation Costs:

- Professional installation may be slightly higher for energy-efficient systems due to additional calibration and setup requirements. However, proper installation ensures maximum performance and savings.

2. Long-Term Savings

- Energy Savings:

- Variable speed pumps adjust motor speed based on demand, reducing energy consumption significantly. These savings are most evident during low-demand periods when the pump operates at reduced speed.

- Example: The HYDROBOX900 can reduce energy consumption by 30%-60%, saving hundreds of dollars annually on electricity bills.

- Maintenance Costs:

- Energy-efficient pumps experience less wear and tear due to features like soft starts and intelligent speed control. This reduces the frequency and cost of repairs and replacements over time.

- Extended Lifespan:

- Optimized operation leads to longer equipment life, delaying the need for costly replacements.

3. Environmental and Regulatory Benefits

- Reduced Carbon Footprint:

- Lower energy consumption translates into reduced greenhouse gas emissions, contributing to environmental sustainability.

- Compliance with Energy Standards:

- Many energy-efficient pumps meet strict regulatory standards, such as ERP compliance (e.g., Stream EA Series with EEI ≤ 0.23). This ensures they align with sustainability goals and may qualify for incentives or rebates.

4. Incentives and Rebates

- Government and Utility Programs:

- Many governments and energy providers offer rebates or incentives for installing energy-efficient equipment, further offsetting the upfront cost.

- Tax Benefits:

- In some regions, installing eco-friendly systems may provide tax deductions or credits.

- Example:

- A homeowner switching to a variable speed booster pump may qualify for rebates covering a portion of the installation cost.

5. Case Study: HYDROBOX900 in Action

- Scenario:

- A family living in a large house with fluctuating water pressure switched from a fixed frequency pump to the HYDROBOX900.

- Results:

- Initial Investment: $1,200 (vs. $600 for a traditional pump).

- Annual Savings: $300 in energy costs due to a 40% reduction in electricity consumption.

- Payback Period: 4 years, after which savings continue to accumulate.

- Additional Benefits: Quieter operation, consistent water pressure, and reduced maintenance expenses.

6. Return on Investment (ROI)

- Quick Payback Period:

- While initial costs are higher, energy-efficient booster pumps typically pay for themselves within 3-5 years through energy savings and reduced maintenance.

- Cumulative Savings:

- Over a 10-year period, homeowners and businesses can save thousands of dollars compared to using a traditional fixed frequency pump.

- Environmental ROI:

- Beyond financial returns, users contribute to a greener planet by reducing energy waste and greenhouse gas emissions.

The cost-benefit analysis of energy-efficient booster pumps demonstrates their clear advantages over traditional models. While the upfront investment may be higher, the long-term savings in energy, maintenance, and environmental impact make them a worthwhile choice. Additionally, rebates and incentives further enhance their affordability.

For homeowners and businesses looking to improve water pressure while reducing costs and supporting sustainability, pumps like the HYDROBOX900 or Stream EA Series offer the perfect solution. By choosing energy-efficient options, you not only save money but also contribute to a more sustainable future.

10. Sustainability and Environmental Impact

In an era where sustainability is a global priority, energy-efficient booster pumps stand out as a key component in reducing energy consumption and promoting environmentally responsible water management. These advanced systems not only save costs but also contribute to a cleaner, greener planet.

1. Reducing Carbon Footprint

- Lower Energy Consumption:

- By operating only as needed, energy-efficient booster pumps significantly reduce electricity use compared to traditional fixed-speed pumps. This directly translates into lower greenhouse gas emissions, as less energy is drawn from fossil fuel-based power sources.

- Example:

- A variable speed pump like the HYDROBOX900 consumes 30%-60% less energy, making it a more sustainable choice for homes, businesses, and industrial applications.

- Cumulative Impact:

- Over a 10-year lifespan, the use of an energy-efficient booster pump can prevent the release of several tons of CO₂ into the atmosphere.

2. Enhancing Sustainable Water Management

- Efficient Water Usage:

- By maintaining consistent pressure and flow, energy-efficient pumps minimize water wastage caused by pressure fluctuations or leaks in pipelines.

- Applications in Sustainable Systems:

- Ideal for integration with rainwater harvesting setups, irrigation systems, and eco-friendly building designs.

- Case Study:

- A large commercial complex using a Stream EA pump series reduced both energy and water waste, aligning with green building certifications like LEED.

3. Supporting Renewable Energy Integration

- Solar-Powered Solutions:

- Energy-efficient booster pumps can be seamlessly paired with solar power systems to create off-grid solutions for homes and businesses. This reduces dependency on non-renewable energy sources and further enhances environmental benefits.

- Hybrid Energy Systems:

- In areas with intermittent solar or wind energy availability, these pumps adapt to hybrid setups, optimizing performance while maintaining sustainability.

4. Compliance with Energy Standards

- Eco-Design Regulations:

- Many energy-efficient booster pumps, such as the Stream EA Series, comply with ERP standards (Energy-Related Products Directive) and have low EEI values (Energy Efficiency Index ≤ 0.23). These certifications ensure the pumps meet stringent energy-saving criteria.

- Green Building Certifications:

- Using energy-efficient pumps can contribute points toward certifications like LEED, BREEAM, or WELL, demonstrating environmental stewardship and energy responsibility.

5. Long-Term Environmental Benefits

- Reduction in Resource Strain:

- With intelligent operation and advanced technologies, these pumps reduce stress on municipal water and power systems, contributing to more sustainable urban and rural infrastructure.

- Promoting Awareness:

- Adopting energy-efficient solutions fosters greater awareness among users about the importance of conserving natural resources and choosing environmentally friendly technologies.

Why Sustainability Matters

Adopting energy-efficient booster pumps isn’t just about reducing costs; it’s about taking responsibility for the environmental impact of water and energy consumption. With global energy demands and water scarcity on the rise, choosing sustainable solutions is critical for protecting the planet for future generations.

Energy-efficient booster pumps, such as the HYDROBOX900 and Stream EA Series, embody the principles of sustainability by reducing energy use, cutting emissions, and supporting eco-friendly water systems. Whether for a home, business, or agricultural setup, these pumps provide a reliable, cost-effective solution that aligns with modern environmental standards.

By investing in energy-efficient pumps, you’re not just enhancing your water system—you’re contributing to a global movement for sustainability, ensuring a better future for the environment and generations to come.

Conclusion

Energy-efficient booster pumps are transforming the way we manage water pressure, offering a blend of cutting-edge technology, cost-effectiveness, and environmental responsibility. These advanced systems are not just a luxury; they’re a necessity in today’s world of rising energy costs and increasing demand for sustainable solutions.

From delivering consistent water pressure to significantly reducing energy consumption, energy-efficient pumps provide numerous benefits for residential, commercial, and industrial applications. Their ability to adapt to real-time water demand ensures optimal performance, while features like variable speed control, smart sensors, and quiet operation make them a standout choice for modern water systems.

By upgrading to an energy-efficient booster pump, you’re not only improving your system’s performance but also contributing to a greener, more sustainable future. With the added advantages of cost savings, extended equipment lifespan, and compliance with energy standards, these pumps offer an unmatched return on investment.

Whether you’re enhancing your home’s water pressure, supporting agricultural irrigation, or managing water supply in a commercial setting, the decision to switch to energy-efficient solutions like the HYDROBOX900 or Stream EA Series is a step toward smarter water management and environmental stewardship.

Take the leap today and experience the benefits of energy-efficient booster pumps—reliable, sustainable, and built for the future.

FAQs: Energy-Efficient Booster Pumps

- What is an energy-efficient booster pump?

An energy-efficient booster pump is a water pressure system designed to minimize energy consumption while maintaining consistent water pressure. These pumps use advanced technologies such as Variable Frequency Drives (VFDs) to adjust motor speed based on real-time water demand, ensuring efficient operation.

- How do energy-efficient booster pumps save energy?

Energy-efficient pumps adjust their speed dynamically to meet water flow and pressure needs. During low-demand periods, they operate at reduced speeds, consuming less electricity compared to traditional fixed-speed pumps that run at maximum capacity regardless of demand.

- What are the benefits of using a variable speed booster pump?

- Constant Water Pressure: Maintains steady pressure even during fluctuating water demand.

- Energy Savings: Reduces power consumption by up to 60%.

- Noise Reduction: Operates more quietly than traditional pumps.

- Extended Lifespan: Minimizes wear and tear on components due to soft starts and optimized operation.

- Are energy-efficient booster pumps suitable for residential use?

Yes, they are ideal for residential use. They provide consistent water pressure across multiple outlets, making them perfect for homes, villas, and apartments. Models like the HYDROBOX900 are specifically designed to enhance domestic water systems.

- What is the difference between fixed frequency and variable speed pumps?

- Fixed Frequency Pumps: Operate at a constant speed, consuming the same amount of energy regardless of water demand.

- Variable Speed Pumps: Adjust their speed based on real-time demand, providing precise water flow and pressure while reducing energy waste.

- How do I select the right booster pump for my needs?

Consider these factors:

- Flow Rate: Measure the volume of water you need per minute.

- Pressure Requirements: Calculate the Total Dynamic Head (TDH) based on the height and resistance in your system.

- System Compatibility: Ensure the pump matches your piping, power supply, and application needs.

- Energy Efficiency: Look for pumps with high EEI ratings (e.g., EEI ≤ 0.23).

- Can energy-efficient pumps be used in commercial or industrial settings?

Yes, energy-efficient booster pumps are versatile and can be used in commercial buildings, hotels, factories, and agricultural irrigation systems. Their ability to handle high demand with optimized energy consumption makes them suitable for larger-scale applications.

- Do energy-efficient pumps require special maintenance?

While maintenance is similar to traditional pumps, energy-efficient models often require less frequent repairs due to their advanced design. Regular tasks include:

- Cleaning filters.

- Inspecting seals and connections for leaks.

- Checking the impeller for wear.

- Ensuring sensors and VFDs are functioning correctly.

- Are energy-efficient booster pumps noisy?

No, they are typically quieter than traditional pumps. Variable speed pumps operate at lower speeds during low-demand periods, reducing noise levels significantly. Some models, like the HYDROBOX900, feature soundproof casings for even quieter operation.

- What is the expected return on investment (ROI) for an energy-efficient pump?

The ROI depends on the pump's initial cost and the energy savings achieved. Most users recover their investment within 3-5 years due to reduced electricity bills and maintenance costs. Over a 10-year period, energy-efficient pumps can save thousands of dollars.

References

https://www.streampumps.com/pump-introductions/hydrobox-up-2024.html

https://www.streampumps.com/pump-introductions/new240712.html

https://www.streampumps.com/pump-introductions/new240712.html

https://www.streampumps.com/pump-knowledge/20231103.html

https://www.streampumps.com/pump-introductions/16.html

Recent Posts

-

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025 -

Single-Stage, Multi-Stage, and Variable Speed Booster Pumps: Which One is Right for You?

1. Introduction Is your shower lacking the invigorating pressure you crave? Do your faucets tri …13th Apr 2025