From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters and every detail can make a significant impact, pressure sensors stand as silent guardians, decoding the language of forces and fluid dynamics. These unassuming devices play a pivotal role across a myriad of industries, from the bustling automotive sector to the sterile environments of medical labs, and the unforgiving terrains of oil and gas exploration.

Imagine a world where the pressure beneath the hood of your car is seamlessly regulated, where medical devices respond with precision in critical moments, and where the depths of the ocean or the vastness of outer space are explored with confidence. This is the realm of pressure sensors, where their silent influence is felt in every application, from the roar of a rocket launch to the delicate dance of pharmaceutical manufacturing.

As we embark on a journey to unravel the intricacies of these unsung heroes, we delve into the certifications and standards that govern their existence, ensuring that they not only meet the demands of their respective industries but also elevate the benchmarks of quality, safety, and reliability. Buckle up as we explore the certifications that make pressure sensors not just instruments of measurement but beacons of excellence in the tapestry of modern technology.

Fig 1. Industry certification

What are the industry-specific certifications of pressure sensors?

Certifications for pressure sensors can vary depending on the industry and the specific requirements of applications. Here are some industry-specific certifications commonly associated with pressure sensors:

- Automotive Industry:

ISO/TS 16949: This is the international standard for quality management in the automotive industry. Pressure sensors used in vehicles often need to meet these standards.

- Medical Industry:

ISO 13485: This is the international standard for quality management systems in the design and manufacturing of medical devices. Pressure sensors used in medical equipment may need to comply with this standard.

- Industrial and Process Control:

ATEX Certification: This is a certification for equipment used in potentially explosive atmospheres. Pressure sensors used in industries such as oil and gas, chemical, or mining may require ATEX certification.

IECEx Certification: Similar to ATEX, IECEx is an international certification for equipment used in explosive atmospheres.

- Aviation and Aerospace:

DO-160: This standard provides environmental test criteria for avionics hardware. Pressure sensors used in aerospace applications may need to comply with DO-160.

- Food and Beverage Industry:

3-A Sanitary Standards: Pressure sensors used in the food and beverage industry may need to meet the hygiene and design standards set by 3-A Sanitary Standards.

- Environmental Monitoring:

IP Rating: Ingress Protection (IP) ratings indicate the level of protection against solids and liquids. Sensors used in outdoor or harsh environments may need a specific IP rating.

- Electronics Industry:

RoHS (Restriction of Hazardous Substances): Compliance with RoHS ensures that the pressure sensor does not contain certain hazardous materials, making it more environmentally friendly.

- Marine Industry:

Lloyd's Register Type Approval: Pressure sensors used in marine applications may need to be approved by classification societies like Lloyd's Register to ensure they meet certain standards.

When selecting a pressure sensor for a specific industry or application, it's essential to check the relevant certifications and standards that apply to ensure the sensor meets the requirements for safety, reliability, and performance. Additionally, regional standards and regulations may also be applicable, so it's crucial to consider those factors based on the location of use.

Fig 2. Automotive industry certification

What are the specific certifications for the oil and gas industry?

In the oil and gas industry, equipment, including pressure sensors, must comply with specific certifications to ensure safety, reliability, and performance. Here are some of the key certifications relevant to pressure sensors in the oil and gas sector:

- ATEX Certification:

ATEX (Atmosphères Explosibles) is a certification required for equipment used in potentially explosive atmospheres. In the oil and gas industry, where flammable gases or dust may be present, ATEX certification is crucial for pressure sensors.

- IECEx Certification:

Like ATEX, IECEx (International Electrotechnical Commission Explosive) certification is an international standard for equipment used in explosive atmospheres. It provides a framework for the global acceptance of equipment in hazardous locations.

- API Standards:

American Petroleum Institute (API) standards are widely adopted in the oil and gas industry. Specific API standards may apply to pressure sensors based on their applications. For example:

- API 6A: Specification for Wellhead and Christmas Tree Equipment

- API 17D: Design and Operation of Subsea Production Systems

- NACE MR0175 / ISO 15156:

NACE International develops standards for corrosion control in various industries, including oil and gas. NACE MR0175 (also known as ISO 15156) provides requirements for the selection and qualification of carbon and low-alloy steels used in equipment such as pressure sensors in oil and gas production environments containing H2S.

- IEC 61508 / IEC 61511:

These standards address the functional safety of electrical/electronic/programmable electronic safety-related systems. Pressure sensors used in safety-critical applications in the oil and gas industry may need to comply with these standards.

- Lloyd's Register Type Approval:

For marine and offshore applications, including the oil and gas sector, equipment, and sensors may require type approval from classification societies such as Lloyd's Register.

- ISO 9001:

While not specific to the oil and gas industry, ISO 9001 certification for quality management systems is generally desirable for suppliers of pressure sensors to ensure consistent quality.

It's important to note that specific requirements may vary depending on the application, location, and type of equipment. Manufacturers and users of pressure sensors in the oil and gas industry should carefully review the relevant standards and regulations to ensure safety and performance requirements compliance. Additionally, local regulatory bodies and industry organizations may impose additional standards and certifications.

What are the specific certifications for the pharmaceutical industry?

In the pharmaceutical industry, equipment, including sensors, must adhere to stringent quality and safety standards to ensure product integrity and compliance with regulatory requirements. Here are some specific certifications and standards relevant to pressure sensors in the pharmaceutical sector:

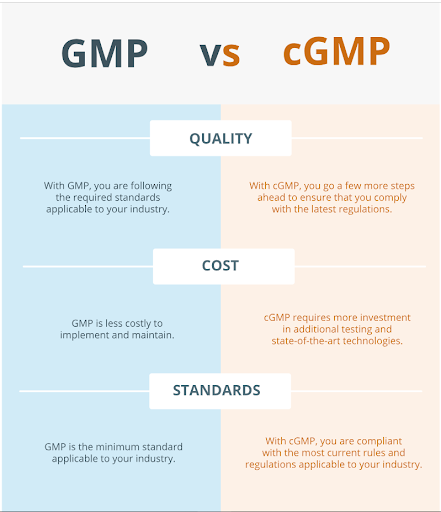

- cGMP (Current Good Manufacturing Practice):

Good Manufacturing Practices are regulations and guidelines set by regulatory agencies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Compliance with cGMP ensures that pharmaceutical products, including equipment like pressure sensors, are consistently produced and controlled to meet quality standards.

- ISO 13485:

ISO 13485 is an international standard specifically for the design and manufacturing of medical devices. While not exclusive to the pharmaceutical industry, pressure sensors used in medical equipment or pharmaceutical processes may need to comply with ISO 13485.

- USP (United States Pharmacopeia):

The United States Pharmacopeia sets standards for the identity, strength, quality, and purity of medicines, food ingredients, and dietary supplements. Pressure sensors used in pharmaceutical processes may need to comply with relevant USP standards.

- FDA Compliance:

Pressure sensors used in pharmaceutical applications may need to comply with regulations set by the U.S. Food and Drug Administration (FDA). While the FDA does not provide specific certifications for sensors, adherence to FDA regulations and guidelines is essential for equipment used in the pharmaceutical manufacturing process.

- ATEX Certification (if applicable):

If pressure sensors are used in areas where explosive atmospheres may be present (e.g., in the production of certain pharmaceuticals), ATEX certification may be required.

- ISO 9001:

ISO 9001 certification for quality management systems is generally desirable for suppliers of pressure sensors in the pharmaceutical industry to ensure consistent quality.

- Cleanroom Certification:

Depending on the specific application, pressure sensors used in pharmaceutical manufacturing processes may need to meet cleanroom standards to prevent contamination.

- GAMP (Good Automated Manufacturing Practice):

GAMP provides guidelines for the validation and control of automated systems in the pharmaceutical industry. If pressure sensors are part of automated systems, compliance with GAMP guidelines may be necessary.

Manufacturers and users of pressure sensors in the pharmaceutical industry need to be aware of and comply with these standards and regulations to ensure the safety, quality, and reliability of the equipment used in pharmaceutical processes. Additionally, regional regulations and specific industry practices may also apply.

Fig 3. GMP VS cGMP

What are the specific certifications for the food industry?

In the food industry, ensuring the safety and quality of equipment is crucial. While there might not be industry-specific certifications for pressure sensors in the food sector, several general certifications and standards are relevant to equipment used in food processing. Here are some certifications and standards that apply to pressure sensors in the food industry:

- FDA Compliance:

The U.S. Food and Drug Administration (FDA) sets regulations and guidelines for equipment used in food processing. Compliance with FDA regulations ensures that pressure sensors meet the necessary safety and hygiene standards.

- EHEDG Certification:

The European Hygienic Engineering & Design Group (EHEDG) provides guidelines and certification for hygienic design in the food industry. EHEDG certification ensures that equipment, including pressure sensors, meets strict hygienic design criteria.

- NSF Certification:

NSF International provides certification for equipment used in food and beverage processing. NSF certification demonstrates that pressure sensors meet specific standards for safety, sanitation, and performance.

- 3-A Sanitary Standards:

3-A Sanitary Standards are widely accepted in the food and beverage industry. Pressure sensors with 3-A certification meet strict hygiene and design standards, ensuring they are suitable for sanitary applications.

- HACCP (Hazard Analysis and Critical Control Points):

While HACCP is more of a system than a certification, it's essential in the food industry. Pressure sensors used at critical points within the food production process should contribute to the overall HACCP plan for ensuring food safety.

- ISO 22000:

ISO 22000 is an international standard for food safety management systems. While not specific to pressure sensors, it provides a framework for ensuring the safety of food-related processes, and adherence to ISO 22000 principles is beneficial for equipment used in the food industry.

- ISO 9001:

ISO 9001 certification for quality management systems is generally desirable for suppliers of pressure sensors in the food industry to ensure consistent quality.

- IP Rating (Ingress Protection):

Pressure sensors used in food processing may need a specific IP rating to protect against dust and moisture. The IP rating indicates the level of protection the equipment provides against these elements.

- Cleanroom Certification (if applicable):

Depending on the specific application, pressure sensors used in food manufacturing processes may need to meet cleanroom standards to prevent contamination.

Manufacturers and users of pressure sensors in the food industry need to be aware of and comply with these standards and certifications to ensure the safety, hygiene, and quality of equipment used in food processing. Additionally, regional regulations and specific industry practices may also apply.

Fig 4. FDA and GMP

What are the beverage certifications in pressure systems?

In the beverage industry, certifications for pressure systems, including pressure sensors, focus on ensuring safety, hygiene, and compliance with industry standards. While there may not be specific certifications exclusively for pressure sensors in beverages, several general certifications and standards are relevant to pressure systems used in the beverage sector. Here are some certifications and standards that may apply:

- FDA Compliance:

The U.S. Food and Drug Administration (FDA) sets regulations and guidelines for equipment used in food and beverage processing. Pressure sensors in the beverage industry should comply with FDA standards to ensure safety and quality.

- 3-A Sanitary Standards:

3-A Sanitary Standards are widely recognized in the food and beverage industry, including the beverage sector. Pressure sensors with 3-A certification meet strict hygiene and design standards suitable for sanitary applications.

- NSF Certification:

NSF International provides certification for equipment used in food and beverage processing, including the beverage industry. NSF certification ensures that pressure sensors meet specific standards for safety, sanitation, and performance.

- EHEDG Certification:

The European Hygienic Engineering & Design Group (EHEDG) provides guidelines and certification for hygienic design in the food and beverage industry. EHEDG certification ensures that equipment, including pressure sensors, meets strict hygienic design criteria.

- ISO 22000:

ISO 22000 is an international standard for food safety management systems. While not specific to pressure sensors, adherence to ISO 22000 principles is beneficial for equipment used in the beverage industry to ensure the safety of beverage-related processes.

- ISO 9001:

ISO 9001 certification for quality management systems is generally desirable for suppliers of pressure sensors in the beverage industry to ensure consistent quality.

- Cleanroom Certification (if applicable):

Depending on the specific application, pressure sensors used in beverage manufacturing processes may need to meet cleanroom standards to prevent contamination.

- IP Rating (Ingress Protection):

Pressure sensors used in beverage processing may need a specific IP rating to protect against dust and moisture. The IP rating indicates the level of protection the equipment provides against these elements.

Manufacturers and users of pressure sensors in the beverage industry need to be aware of and comply with these standards and certifications to ensure the safety, hygiene, and quality of equipment used in beverage processing. Additionally, regional regulations and specific industry practices may also apply.

Fig 5. Some food certification

Industry-specific certification in the pressure sensor case

Certainly! Let's delve into more detail about each of the industry-specific certifications mentioned earlier in the context of pressure sensors:

- Automotive Industry:

ISO/TS 16949: This is the international standard for quality management in the automotive industry. Pressure sensors used in vehicles are expected to comply with this standard to ensure high-quality manufacturing processes and product consistency.

- Medical Industry:

ISO 13485: Specifically designed for the medical device industry, ISO 13485 sets out the requirements for a quality management system. Pressure sensors used in medical equipment must adhere to this standard to meet strict safety and reliability criteria.

- Industrial and Process Control:

ATEX Certification: Essential for equipment used in potentially explosive atmospheres, ATEX certification is crucial for pressure sensors in industries such as oil and gas, chemical, and mining.

IECEx Certification: An international standard equivalent to ATEX, IECEx is particularly relevant for equipment used in explosive atmospheres, ensuring global acceptance.

- Aviation and Aerospace:

DO-160: This standard provides environmental test criteria for avionics hardware. Pressure sensors used in aerospace applications must comply with DO-160 to ensure they can withstand the environmental conditions associated with aviation.

- Food and Beverage Industry:

3-A Sanitary Standards: Widely recognized in the food and beverage industry, 3-A certification ensures that pressure sensors meet strict hygiene and design standards for sanitary applications.

NSF Certification: NSF certification is relevant for equipment used in food and beverage processing, indicating that pressure sensors meet safety, sanitation, and performance standards.

- Oil and Gas Industry:

ATEX Certification: Ensures that equipment, including pressure sensors, used in potentially explosive atmospheres in the oil and gas industry meets strict safety criteria.

IECEx Certification: Similar to ATEX, IECEx certification is an international standard for equipment used in explosive atmospheres in various industries, including oil and gas.

- Pharmaceutical Industry:

cGMP (Current Good Manufacturing Practice): Ensures that pressure sensors, as part of the manufacturing process, comply with regulations for consistent production and control of pharmaceutical products.

ISO 13485: Relevant for pressure sensors used in medical devices, including those in pharmaceutical manufacturing processes.

- Beverage Industry:

3-A Sanitary Standards: Applicable in the beverage industry, ensuring that pressure sensors meet strict hygiene and design standards for sanitary applications.

NSF Certification: Important for equipment used in beverage processing, indicating that pressure sensors meet safety, sanitation, and performance standards.

- Cleanroom Certification (if applicable):

A certification indicating that pressure sensors meet specific cleanliness standards is crucial in industries where contamination must be minimized, such as pharmaceuticals, food, and electronics manufacturing.

- IP Rating (Ingress Protection):

Indicates the level of protection against solids and liquids, important for pressure sensors in various industries, especially those where exposure to dust or moisture is a concern.

- Lloyd's Register Type Approval:

Relevant for marine and offshore applications, ensuring that equipment, including pressure sensors, meets the standards set by classification societies like Lloyd's Register.

It's important to note that while these certifications provide a framework for quality, safety, and compliance, industry-specific regulations and standards can vary globally. Manufacturers and users of pressure sensors should consider the specific requirements of their application and location to ensure full compliance with relevant standards and regulations.

Fig 6. 3-A sanitary marking

What are the Aviation and aerospace-specific certifications for pressure sensors?

In the aviation and aerospace industry, pressure sensors play a critical role in various applications, including aircraft systems and space exploration. While there may not be specific certifications exclusively for pressure sensors, these sensors are often required to meet stringent standards to ensure reliability, safety, and performance in the demanding environments of aviation and aerospace. Here are some of the key standards and certifications relevant to pressure sensors in the aviation and aerospace sector:

- DO-160:

- Description: DO-160 is a standard published by RTCA, Inc. (Radio Technical Commission for Aeronautics), outlining environmental conditions and test procedures for airborne equipment.

- Relevance to Pressure Sensors: Pressure sensors used in avionics hardware must comply with DO-160 to demonstrate their ability to withstand environmental conditions such as temperature, humidity, vibration, and electromagnetic interference.

- RTCA/DO-178C (Software Considerations in Airborne Systems and Equipment Certification):

- Description: This standard provides guidelines for the development of airborne systems software.

- Relevance to Pressure Sensors: If the pressure sensor incorporates software components, compliance with DO-178C may be necessary to ensure the reliability and safety of the software.

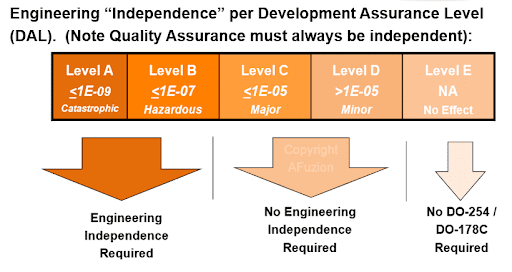

- RTCA/DO-254 (Design Assurance Guidance for Airborne Electronic Hardware):

- Description: DO-254 guides the design assurance of airborne electronic hardware.

- Relevance to Pressure Sensors: Pressure sensors, as electronic hardware in avionics systems, may need to comply with DO-254 to ensure their design meets the necessary safety and reliability standards.

- MIL-STD-810:

- Description: MIL-STD-810 is a standard issued by the U.S. Department of Defense for environmental testing procedures, covering a range of conditions including temperature, humidity, and vibration.

- Relevance to Pressure Sensors: Pressure sensors used in military aviation applications may need to comply with MIL-STD-810 to demonstrate their ability to withstand harsh environmental conditions.

- RTCA/DO-178C (Software Considerations in Airborne Systems and Equipment Certification):

- Description: This standard provides guidelines for the development of airborne systems software.

- Relevance to Pressure Sensors: If the pressure sensor incorporates software components, compliance with DO-178C may be necessary to ensure the reliability and safety of the software.

- ASTM E595 (Outgassing of Spacecraft Materials):

- Description: ASTM E595 provides a standard test method for determining the volatile content of materials when exposed to a vacuum environment.

- Relevance to Pressure Sensors: Pressure sensors used in space applications may need to comply with ASTM E595 to ensure low outgassing characteristics in a vacuum.

- AS9100 (Quality Management Systems - Aerospace Requirements):

- Description: AS9100 is a standard for quality management systems in the aerospace industry.

- Relevance to Pressure Sensors: Manufacturers of pressure sensors may adhere to AS9100 to ensure their quality management systems meet aerospace industry standards.

It's important to note that the specific requirements for pressure sensors in aviation and aerospace can vary based on the intended application and the regulations of relevant aviation authorities, such as the Federal Aviation Administration (FAA) in the United States or the European Union Aviation Safety Agency (EASA) in Europe. Manufacturers and users should carefully review and comply with the applicable standards and requirements for their specific use case.

Fig 7. DO-178 introduction

What is an IP Rating for a pressure sensor?

The IP rating, or Ingress Protection rating, is a standardized classification system used to indicate the level of protection that an electrical device, such as a pressure sensor, provides against the intrusion of solids and liquids. The IP rating is commonly used to specify the environmental protection of electronic devices, including sensors, in various industries.

The IP rating is composed of two digits, each with a specific meaning:

- First Digit (Solids Protection):

- The first digit ranges from 0 to 6 and indicates the level of protection against the ingress of solid objects like dust or particles.

- Example:

- IP0X: No protection against solids.

- IP6X: Complete protection against dust.

- Second Digit (Liquids Protection):

- The second digit ranges from 0 to 9 and indicates the level of protection against the ingress of liquids.

- Example:

- IPX0: No protection against liquids.

- IPX8: Protection against continuous immersion in water under specified conditions.

For pressure sensors, a higher IP rating generally signifies better protection against environmental factors. The specific IP rating required for a pressure sensor depends on the application and the conditions in which it will operate. Here are a few examples:

- IP67: This is a common rating for pressure sensors used in industrial and outdoor applications. It means the sensor is protected against dust and can be submerged in water up to 1 meter for a limited duration.

- IP68: This rating indicates a higher level of protection against dust, and the sensor is designed to withstand continuous immersion in water under specific conditions. It is suitable for applications where the sensor may be exposed to water for extended periods.

- IP69K: This is a robust rating designed for applications in harsh environments, such as those with high-pressure water jets or steam cleaning. IP69K-rated sensors can withstand high-temperature and high-pressure washdowns.

When selecting a pressure sensor, it's important to consider the environmental conditions in which it will be used and choose an IP rating that provides adequate protection for the specific application. Manufacturers typically specify the IP rating of their sensors, making it easier for users to select sensors that meet the required environmental standards for their intended use.

Why is cleanroom certification needed in pressure systems?

Cleanroom certification is important in pressure systems, including pressure sensors, when these systems are utilized in environments where maintaining a controlled and sterile atmosphere is crucial. Cleanrooms are spaces designed to control airborne particulate contamination, temperature, humidity, and other environmental factors. These controlled environments are common in industries such as pharmaceuticals, biotechnology, electronics manufacturing, aerospace, and healthcare. Here are several reasons why cleanroom certification is necessary in pressure systems within these industries:

- Avoid Contamination:

Cleanrooms are designed to minimize the presence of airborne particles, dust, and contaminants. In industries like pharmaceuticals and electronics manufacturing, even tiny particles can adversely affect product quality and performance. Pressure sensors operating in such environments need to meet strict cleanliness standards to prevent contamination of sensitive processes or products.

- Maintain Product Quality:

Many industries, such as pharmaceuticals and biotechnology, have stringent quality control standards. Pressure sensors play a critical role in monitoring and controlling processes. Cleanroom certification ensures that pressure sensors meet cleanliness criteria, contributing to the overall quality and reliability of the products or processes they are monitoring.

- Compliance with Industry Regulations:

Some industries, like pharmaceuticals and healthcare, are subject to regulatory standards (e.g., Good Manufacturing Practice - GMP). Cleanroom certification ensures that pressure sensors meet the regulatory requirements for cleanliness and environmental control.

- Prevent Process Interruptions:

Contaminants in critical processes can lead to disruptions and downtime. Pressure sensors, being integral components in many automated systems, must operate reliably to prevent interruptions in manufacturing or other critical processes. Cleanroom certification helps ensure the continued performance of pressure sensors in such environments.

- Ensure Accuracy and Reliability:

In precision manufacturing processes or research environments, maintaining accurate and reliable measurements is essential. Cleanroom certification ensures that pressure sensors perform accurately in controlled environments, contributing to the precision of measurements and control systems.

- Prevent Damage to Sensitive Equipment:

In some industries, sensitive equipment or materials may be present. Contamination can damage such equipment or compromise the quality of materials. Cleanroom-certified pressure sensors help protect sensitive components from contamination.

- Adherence to Cleanroom Classes:

Cleanrooms are classified based on the allowable particle count in the air. Pressure sensors must meet the cleanliness requirements of the specific cleanroom class in which they are intended to operate. Cleanroom certification ensures that pressure sensors are suitable for the designated cleanroom class.

In summary, cleanroom certification is necessary for pressure systems, particularly pressure sensors, to meet the strict cleanliness and environmental control requirements of industries where maintaining a controlled atmosphere is essential for product quality, precision manufacturing, and compliance with regulatory standards. The certification process involves testing and verification to ensure that the pressure sensors can operate effectively in cleanroom environments without introducing contaminants.

Fig 8. Some different industry certifications

What are the industry regulations and standards for pressure sensors?

ISO 9001 (Quality Management Systems): ISO 9001 is an international standard that sets out the criteria for a quality management system (QMS). It is designed to help organizations ensure that their products and services consistently meet customer requirements while enhancing customer satisfaction. For pressure sensor manufacturers, ISO 9001 certification signifies a commitment to quality management, process improvement, and customer-focused practices, which can lead to increased efficiency and customer trust.

- ATEX (Atmosphères Explosibles): ATEX is a European Union directive that defines the requirements for equipment used in potentially explosive atmospheres. In the context of pressure sensors, ATEX certification ensures that the sensors are designed and manufactured to operate safely in environments where explosive gases, vapors, or dust may be present. Compliance with ATEX standards is crucial for pressure sensors used in industries such as oil and gas, chemical processing, and mining.

- IECEx (International Electrotechnical Commission Explosive): IECEx is an international certification scheme that facilitates the global acceptance of equipment used in explosive atmospheres. Similar to ATEX, IECEx certification is relevant for pressure sensors designed for use in potentially explosive environments. It ensures that the sensors meet international standards for safety in hazardous areas, allowing for easier acceptance in markets worldwide.

- ISO 13485 (Medical Devices - Quality Management Systems): ISO 13485 is an international standard specifically tailored for the design and manufacturing of medical devices. Pressure sensors intended for medical applications must adhere to ISO 13485 to demonstrate compliance with quality management practices that prioritize patient safety, product reliability, and regulatory requirements.

- DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment): DO-160 is a standard published by RTCA, Inc., outlining environmental conditions and test procedures for airborne equipment in the aviation industry. Pressure sensors used in avionics must comply with DO-160 to ensure their resilience to various environmental factors such as temperature, humidity, and electromagnetic interference, contributing to the safety and reliability of aviation systems.

- NACE MR0175 / ISO 15156 (Materials for Use in H2S-Containing Environments in Oil and Gas Production): NACE MR0175, also known as ISO 15156, provides requirements for the selection and qualification of materials, including pressure sensors, used in environments containing hydrogen sulfide (H2S). Compliance with this standard is essential for pressure sensors deployed in oil and gas production, ensuring materials are resistant to corrosion in H2S-containing atmospheres.

- 3-A Sanitary Standards (Sanitary Design and Fabrication of Food Processing Equipment): 3-A Sanitary Standards are widely accepted in the food and beverage industry, ensuring the hygienic design and fabrication of equipment, including pressure sensors, used in food processing. Compliance with these standards is crucial for pressure sensors to meet strict hygiene requirements, preventing contamination and ensuring the safety of food products.

These industry regulations and standards play a vital role in establishing best practices, ensuring safety, and enhancing the quality and reliability of pressure sensors across various applications and sectors.

How should notice that a pressure sensor does have certifications?

To determine whether a pressure sensor has certifications, you can follow these steps:

- Check Product Documentation:

Review the product documentation provided by the sensor manufacturer. Certifications and compliance information are often included in user manuals, datasheets, or technical specifications. Look for sections that detail certifications, standards compliance, or regulatory approvals.

- Manufacturer's Website:

Visit the official website of the pressure sensor manufacturer. Manufacturers often provide detailed information about their products, including certifications and compliance with industry standards. Look for dedicated pages or sections related to product specifications, certifications, or quality assurance.

- Product Labeling:

Inspect the physical labeling on the pressure sensor itself. Manufacturers may include certification labels or markings directly on the sensor housing. Common certification labels include CE (European Conformity), ATEX, IECEx, and others depending on the industry and region.

- Datasheets and Technical Specifications:

Refer to the product datasheets and technical specifications, which are typically available on the manufacturer's website or in product documentation. These documents often contain detailed information about the sensor's features, performance, and any certifications or standards it complies with.

- Certification Documents:

If available, request certification documents directly from the manufacturer. This may include official certificates or test reports issued by third-party certification bodies. These documents can provide detailed information about the sensor's compliance with specific standards.

- Contact the Manufacturer:

If you cannot find the information you need through documentation or online resources, consider reaching out to the manufacturer directly. Manufacturers often have customer support or technical support teams that can provide clarification on certifications, compliance, and other product-related inquiries.

- Authorized Distributors:

If you are purchasing the pressure sensor through a distributor, inquire about certifications from the distributor. Authorized distributors often have access to comprehensive information about the products they sell and can assist with questions regarding certifications.

- Industry-Specific Websites or Databases:

Some industries maintain databases or websites where you can verify certifications for specific products. For example, organizations overseeing ATEX or IECEx certifications may have online databases where you can check the certification status of a particular pressure sensor.

Remember that certifications can vary depending on the industry and application. It's crucial to ensure that the pressure sensor has the necessary certifications relevant to your specific use case and compliance requirements. If in doubt, consult with the manufacturer or seek advice from industry experts familiar with the standards applicable to your application.

How can Compliance with industry regulations and standards for pressure sensors?

Ensuring compliance with industry regulations and standards for pressure sensors is crucial to guarantee their reliability, safety, and performance in various applications. Here's a general guide on how to achieve compliance:

- Understand Applicable Standards:

Identify the relevant industry standards and regulations that apply to pressure sensors in your specific application. Different industries and sectors may have unique standards, and compliance requirements can vary.

- Review Product Specifications:

Thoroughly review the technical specifications and documentation provided by the pressure sensor manufacturer. Look for information on certifications, standards compliance, and regulatory approvals. The product datasheet and user manual are good places to start.

- Verify Certifications:

Check for certification labels or markings on the pressure sensor itself. Common certifications include CE (for European Conformity), ATEX, IECEx, and others depending on the industry. Ensure that the certifications listed align with the standards required for your application.

- Consult with Certification Bodies:

If uncertainty exists, consult with relevant certification bodies or agencies that oversee compliance in your industry. These organizations can guide the specific standards applicable to pressure sensors and verify the authenticity of certifications.

- Ensure Traceability and Documentation:

Pressure sensor manufacturers should provide comprehensive documentation, including certification documents, test reports, and quality assurance records. Ensure that the documentation is traceable and can be referenced back to specific tests and standards.

- Work with Reputable Suppliers:

Source pressure sensors from reputable and reliable suppliers. Established manufacturers with a history of quality assurance are more likely to produce sensors that meet industry standards. Consider supplier reputation, certifications, and industry experience when selecting a supplier.

- Follow Installation and Maintenance Guidelines:

Adhere to the installation, operation, and maintenance guidelines provided by the manufacturer. Proper installation and regular maintenance are crucial for maintaining compliance and ensuring the ongoing reliability of pressure sensors.

- Periodic Calibration and Testing:

Implement a regular calibration and testing schedule for pressure sensors. This ensures that the sensors continue to meet performance requirements over time. Calibration should be performed according to industry standards, and records should be maintained.

- Stay Informed About Updates:

Industry standards may evolve. Stay informed about updates or revisions to relevant standards that may impact the compliance of pressure sensors. Manufacturers may also release updated product versions to meet new requirements.

- Engage with Industry Associations:

Participate in industry associations or forums related to your specific application. These forums provide valuable insights into industry trends, best practices, and changes in regulations. Networking with industry professionals can also offer guidance on compliance.

Remember that achieving and maintaining compliance is an ongoing process. Regularly review industry standards, stay informed about changes, and work collaboratively with manufacturers and certification bodies to ensure that pressure sensors meet the requirements for your application.

Some Examples of every industry-specific certification and their requirements for pressure sensors

Here are examples of industry-specific certifications and their requirements for pressure sensors across various sectors:

- Automotive Industry:

ISO/TS 16949:

Requirements: ISO/TS 16949 specifies quality management system requirements for the design, development, production, and, when relevant, installation and service of automotive-related products. Pressure sensors in the automotive industry need to adhere to these standards to ensure consistent quality and reliability.

- Medical Industry:

ISO 13485:

Requirements: ISO 13485 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and regulatory requirements. Pressure sensors used in medical devices must comply with these standards to ensure patient safety and product reliability.

- Oil and Gas Industry:

ATEX Certification:

Requirements: ATEX certification is required for equipment used in potentially explosive atmospheres in the oil and gas industry. Pressure sensors must be designed to prevent the risk of ignition in the presence of flammable gases or dust, meeting specific safety and design criteria.

- Aerospace Industry:

DO-160:

Requirements: DO-160 outlines environmental test criteria for avionics hardware. Pressure sensors in the aerospace industry must undergo testing for factors such as temperature, humidity, and vibration to ensure their resilience in airborne systems.

- Food and Beverage Industry:

3-A Sanitary Standards:

Requirements: 3-A Sanitary Standards define hygienic design and fabrication criteria for equipment used in the food and beverage industry. Pressure sensors must meet strict hygiene standards to prevent contamination of food products.

- Pharmaceutical Industry:

cGMP (Current Good Manufacturing Practice):

Requirements: Pressure sensors in the pharmaceutical industry must adhere to cGMP regulations, ensuring that they are designed, manufactured, and maintained to meet quality standards and prevent contamination.

- Cleanroom Environments:

ISO 14644 (Cleanrooms and Associated Controlled Environments):

Requirements: ISO 14644 specifies cleanliness levels in cleanrooms and associated controlled environments. Pressure sensors used in cleanrooms must meet the particle count and environmental requirements defined by ISO 14644.

- Automated Systems:

IEC 61508 / IEC 61511 (Functional Safety):

Requirements: These standards address the functional safety of electrical/electronic/programmable electronic safety-related systems. Pressure sensors in automated systems need to comply with these standards to ensure their reliability in safety-critical applications.

- Marine Industry:

Lloyd's Register Type Approval:

Requirements: Lloyd's Register provides type approval for equipment used in the marine industry. Pressure sensors must meet specific standards to ensure their suitability for marine applications.

- Environmental Monitoring:

IP Rating (Ingress Protection):

Requirements: The IP rating indicates the level of protection against solids and liquids. Pressure sensors used in environmental monitoring applications, such as weather stations, may need a specific IP rating to withstand outdoor conditions.

Conclusion

It's important to note that these certifications may have specific requirements and testing procedures that pressure sensor manufacturers must follow to ensure compliance. The exact requirements may vary depending on the nature of the equipment, the industry, and regional regulations. Manufacturers should carefully review and meet the relevant certification criteria for their target markets.

In conclusion, ensuring compliance with industry-specific certifications and standards is imperative for pressure sensors across diverse sectors. Certifications such as ISO/TS 16949, ISO 13485, ATEX, DO-160, 3-A Sanitary Standards, cGMP, and others establish rigorous criteria for quality, safety, and performance in automotive, medical, oil and gas, aerospace, food and beverage, pharmaceutical, cleanroom, automated systems, marine, and environmental monitoring applications.

Pressure sensor manufacturers and users should diligently review product documentation, verify certifications through labels or markings, consult with relevant certification bodies, and stay informed about industry updates. Additionally, adherence to installation guidelines, periodic calibration, and collaboration with reputable suppliers contribute to maintaining compliance.

Ultimately, the commitment to meeting industry regulations not only ensures the reliability and safety of pressure sensors but also underscores the manufacturers' dedication to quality management, customer satisfaction, and adherence to best practices within their respective sectors.

To recap

1. What is the significance of industry-specific certifications for pressure sensors?

Answer: Industry-specific certifications for pressure sensors are crucial as they ensure that these devices meet established standards, regulations, and quality benchmarks. Certifications validate their reliability, safety, and performance in specific applications, instilling confidence in users across diverse sectors.

2. Are pressure sensors used in the automotive industry subject to any specific certification?

Answer: Yes, pressure sensors in the automotive industry often adhere to the ISO/TS 16949 standard. This certification sets quality management system requirements, ensuring that sensors meet the stringent criteria for design, production, and service in the automotive sector.

3. What certifications are essential for pressure sensors in the medical field?

Answer: Pressure sensors in the medical industry should comply with ISO 13485. This standard outlines the requirements for a quality management system, emphasizing the design and manufacturing of medical devices to ensure both patient safety and regulatory compliance.

4. Why is ATEX certification crucial for pressure sensors in the oil and gas industry?

Answer: ATEX certification is vital for pressure sensors in the oil and gas sector as it ensures the devices' safety in potentially explosive atmospheres. ATEX-certified sensors meet specific design and performance criteria to prevent ignition risks in hazardous environments.

5. What role does DO-160 play in the aerospace industry for pressure sensors?

Answer: DO-160 sets environmental test criteria for avionics hardware. In the aerospace industry, pressure sensors must comply with DO-160 to prove their resilience to various environmental factors such as temperature, vibration, and electromagnetic interference, ensuring reliability in airborne systems.

6. How do 3-A Sanitary Standards impact pressure sensors in the food and beverage industry?

Answer: 3-A Sanitary Standards are crucial for pressure sensors in the food and beverage sector as they define hygienic design criteria. Compliance ensures that sensors meet strict hygiene standards, preventing contamination and ensuring the safety of food products.

7. Why is cleanroom certification necessary for pressure sensors in certain environments?

Answer: Cleanroom certification is essential for pressure sensors in environments with controlled cleanliness requirements. It verifies that the sensors meet stringent standards, preventing contamination in applications such as pharmaceuticals, electronics manufacturing, and healthcare.

8. Are there any specific certifications for pressure sensors used in hazardous marine environments?

Answer: Lloyd's Register Type Approval is relevant for pressure sensors in the marine industry. This certification ensures that sensors meet specific standards for suitability in marine applications, providing confidence in their performance and reliability.

9. How does IEC 61508 contribute to the functional safety of pressure sensors in automated systems?

Answer: IEC 61508 addresses the functional safety of electronic safety-related systems. Compliance with this standard is crucial for pressure sensors in automated systems, ensuring their reliability and safety in critical applications.

10. Are there any certifications specifically addressing the cleanliness of pressure sensors?

Answer: The Ingress Protection (IP) rating is relevant for assessing the cleanliness protection of pressure sensors. It indicates the level of protection against solids and liquids, providing insight into the sensor's suitability for specific environmental conditions.

References

https://blog.pacificcert.com/iso-certifications-for-automotive-industry-requirements-and-benefits/

https://blog.spcollege.edu/careers-internships/industry-certification-explained/

https://www.linkedin.com/pulse/certifications-world-sustainable-textile

https://www.linkedin.com/pulse/gmp-certification-pharmaceuticals-zenvision-pharma

https://www.linkedin.com/pulse/food-safety-certifications-david-strait

https://www.mtgspa.com/en/insights/3a-sanitary-standards

https://www.simplerqms.com/cgmp/

Recent Posts

-

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025 -

Single-Stage, Multi-Stage, and Variable Speed Booster Pumps: Which One is Right for You?

1. Introduction Is your shower lacking the invigorating pressure you crave? Do your faucets tri …13th Apr 2025 -

Process Connection Unveiled: Decoding the Art of Pressure Sensor Fittings

Process Connection or Fitting of a Pressure Transmitter The process connection or fitting of a …5th Apr 2025