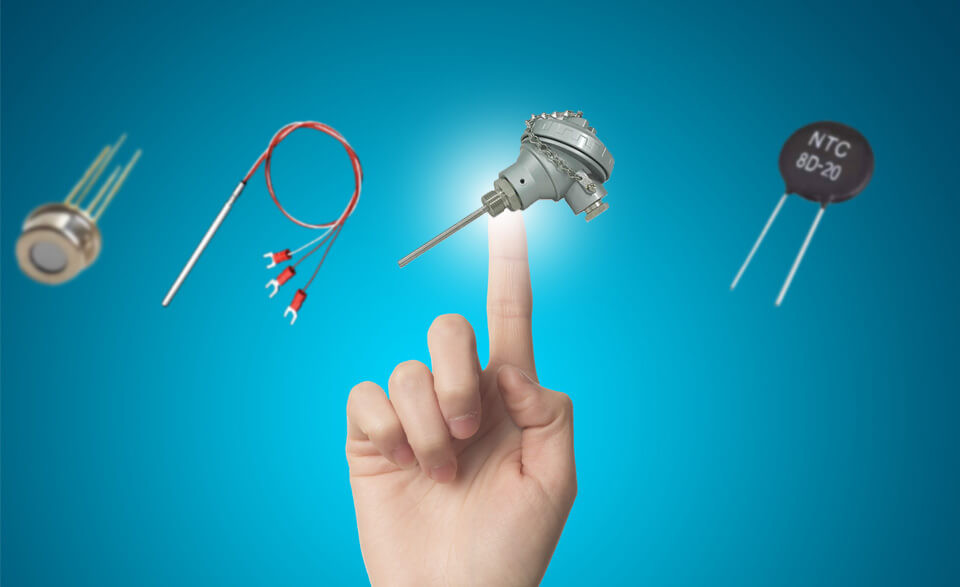

How to Choose a Temperature Sensor?

In industrial environments having a robust temperature sensor is necessary because determining temperature is one of the most important things an engineer needs to design for. an optimal and right temperature sensor can minimize cost without compromising performance, accuracy, or reliability. So, you should recognize the importance of the selection of temperature sensors for the requirements of an application. There are several factors to consider when choosing a sensor. We provide a guide outlined below to help you in making the appropriate selection of the perfect sensor for different applications.

Temperature Range

When selecting a temperature sensor for an application, the temperature range should be the first thing to consider. Different temperature sensors are made suitable for different ranges.

The NTC thermistors are suitable for applications ranging from -50 to +250 degrees Celsius and are therefore suitable for a wide range of applications.

Thermocouples lack high accuracy at lower temperatures but are capable of measuring temperatures up to 2,000 degrees Celsius.

Accuracy

Another important consideration is the required accuracy. Although thermocouples are low cost, they often have less accuracy over time than a thermistor temperature probe.

NTC thermistors and thermistor probes have the most accurate performance between -50°C and +150°C and can be very accurate at 250°C if they are enclosed in glass.

Stability

Stability will affect the type of temperature sensor which is used.

Temperature sensors Depending on the structure, materials that are made of them and packaging can have less performance and become less effective over time.

During a year, a thermistor depending on whether it is hermetically sealed or not can change between 0.02°C and 0.2°C. A thermocouple can change between 1°C and 2°C during a year.

Size or Packaging Style

The packaging style will vary depending on the application at hand. A threaded stud is likely to be used for some general-purpose applications.

The closed tubes are a preferred choice for applications that include liquid measurements. Ring terminals and other thin round metal stampings can be used for surface sensing.

Noise Immunity

The NTC thermistors have high resistance when the initial switch makes them immune to electrical noise and lead resistance. Thermocouples are also protected to lead resistance. Although due to the small output signal, they can be affected by electrical noise.

Stem (Sheath)

Thermocouples and RTD are supplied with 316 stainless steel stem and internal wiring with powdered ceramics. spring-loaded and welded are two types of screw head styles. The spring-loaded stem is built at the bottom of the thermo well and offers maximum heat sensitivity. The welded stem is proper for use in liquid applications.

Insertion (U) Length

The depth of the procedure of a thermocouple or RTD is indicated by insertion (U) length. Thermocouples and RTDs are available in lengths from 2″ to 24,” which are standard U-lengths. Special orders and consultations with the manufacturer are essential for Other lengths.

Measuring (Hot) Junction

There are different types of thermocouples and they use ceramic cover insulation to present the measuring junction. The RTD is a block of platinum which is usually a 3 - wire model and it is done at 0 ° C with 100 Ω resistance to 1000 Ω.

Connection (Termination)

Thermocouples are usually provided with a mating jack, terminal block, or integrated lead-wire ports. The extension wire should be adapted to the thermocouple type, otherwise, multiple junctions are generated.

This causes an incorrect identification of the temperature. RTD usually possesses a terminal block or lead-wire connection.

As the connection of the terminal block does not have a lead wire, an extension wire should be connected to the detector or controller.

Still curious? Click on the below links to know more:

Common Applications of Temperature Sensors

Recent Posts

-

Troubleshooting Common Water Pump Problems: A Step-by-Step Guide

Introduction Water pumps are essential components in a wide range of settings, from homes and farms …1st Apr 2025 -

Boosting Agricultural Efficiency: Centrifugal Water Pumps

1. Introduction Agricultural irrigation is crucial in maintaining consistent crop growth and ensurin …28th Mar 2025 -

The Ultimate Guide to Launching a Robotic Coffee Business

The Ultimate Guide to Launching a Robotic Coffee BusinessTable of ContentSEOFAQ - CatalogSales Advic …28th Mar 2025