Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Welcome to the world of performance certification, where products undergo rigorous assessments to prove their mettle! In a landscape filled with technological marvels and innovations, ensuring that a product not only meets but exceeds expectations is paramount. Performance certification is the golden stamp of approval, a testament to a product's ability to shine in the real world.

Ever wondered what makes your favorite gadgets reliable, your machinery trustworthy, and your medical devices truly life-saving? It's the meticulous process of performance certification. This journey takes products through a gauntlet of tests, ensuring they don't just work but work exceptionally well. From accuracy to reliability, these certifications vouch for a product's prowess, giving you the confidence to choose the best in a sea of options.

In this exploration of performance certification, we delve into the intricacies that make products stand out. What does it mean for a pressure sensor to be ATEX-certified? Why is ISO 9001 more than just a number? Join us on a journey where standards meet excellence, and certifications transform products into beacons of trust. Let's unravel the mysteries behind the stamps that turn ordinary products into extraordinary performers!

Fig 1. Pressure sensor certifications

What is the pressure sensor performance certification?

Pressure sensor performance certification involves assessing and validating the sensor's ability to accurately and reliably measure pressure within specified ranges and conditions. The certification process typically includes various tests and evaluations to ensure that the sensor meets specific performance criteria. These criteria may include accuracy, repeatability, sensitivity, response time, and stability under different environmental conditions.

One critical aspect of pressure sensor performance certification is accuracy. Accuracy refers to the sensor's ability to provide pressure measurements that closely match the true or expected values. Calibration procedures are often employed to verify and adjust the sensor's output to meet specified accuracy standards. Calibration may involve exposing the sensor to known pressure conditions and comparing its output to the expected values, allowing adjustments to be made if necessary.

Repeatability is another important factor in performance certification. Repeatability assesses the sensor's consistency in providing the same output when subjected to the same input under identical conditions. A reliable pressure sensor should exhibit minimal variation in its measurements during repeated tests. Additionally, performance certification may involve evaluating the sensor's sensitivity, which measures the change in output relative to a change in pressure. A high-sensitivity sensor can detect small pressure variations accurately.

In summary, pressure sensor performance certification involves comprehensive testing to ensure the sensor meets specified criteria for accuracy, repeatability, and sensitivity. This certification process provides confidence in the sensor's ability to deliver reliable and consistent pressure measurements, making it suitable for various applications across industries such as automotive, aerospace, industrial automation, and medical devices. Meeting performance standards is crucial for maintaining the quality and reliability of pressure sensors in diverse operational environments.

What is the pressure sensor certification?

Pressure sensors can undergo various certifications depending on their intended use and the industry standards they need to meet. Some common certifications for pressure sensors include:

- CE Marking: This is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that the product complies with the essential requirements of relevant European health, safety, and environmental protection legislation.

- RoHS Compliance: Restriction of Hazardous Substances (RoHS) is a directive that restricts the use of specific hazardous materials in electronic and electrical equipment. Pressure sensors used in electronic devices may need to comply with RoHS regulations.

- UL Certification: Underwriters Laboratories (UL) is a safety certification organization. Pressure sensors used in various applications, especially in industrial settings, may undergo UL certification to ensure they meet safety standards.

- ATEX Certification: ATEX is a European directive that applies to equipment used in potentially explosive atmospheres. Pressure sensors used in environments where there is a risk of explosion may need ATEX certification.

- IECEx Certification: The International Electrotechnical Commission (IEC) issues certifications for products used in explosive atmospheres. IECEx certification is recognized globally and ensures compliance with international standards.

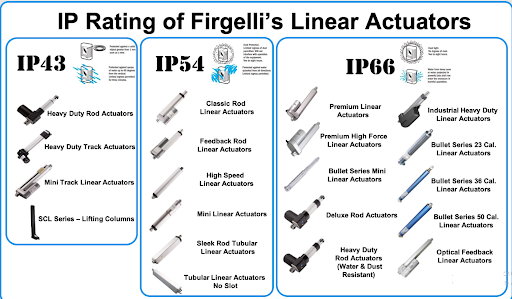

- IP Rating: Ingress Protection (IP) ratings indicate the degree of protection provided by an enclosure against the intrusion of solid objects (like dust) and liquids. While not a certification in itself, pressure sensors may be designed and tested to meet specific IP ratings depending on their application.

- ISO Certification: While ISO certification is not specific to pressure sensors, manufacturers may obtain ISO 9001 certification for their quality management systems, ensuring that their products meet certain quality standards.

- NIST Traceability: The National Institute of Standards and Technology (NIST) provides traceable calibration standards. Pressure sensors used in critical applications may be calibrated against NIST standards to ensure accuracy.

- FDA Compliance: Pressure sensors used in medical devices or applications related to food and pharmaceuticals may need to comply with regulations set by the U.S. Food and Drug Administration (FDA).

It's essential to check the specific requirements and regulations applicable to the industry and application where the pressure sensor will be used. Different regions and industries may have specific standards and certifications that need to be met.

Fig 2. Pressure sensor different certifications

What is a CE certification?

CE certification, which stands for Conformité Européenne (European Conformity), is a mandatory marking for products sold within the European Economic Area (EEA). It indicates that a product complies with essential health, safety, and environmental protection requirements set by European Union (EU) directives. The CE mark is not a quality or performance certification; instead, it affirms that the product meets the minimum legal requirements for safety and environmental impact, allowing it to be freely marketed and sold within the EEA.

To obtain CE certification, manufacturers must follow a process that involves assessing their products' conformity with relevant EU directives. The specific requirements vary depending on the type of product, and third-party testing or certification bodies may be involved in the evaluation process. The CE mark is affixed to the product or its accompanying documentation, signaling to authorities, consumers, and other stakeholders that the product has undergone the necessary assessments and meets the EU's safety and environmental standards, facilitating its free movement within the European market.

Fig 3. CE marking on pressure transducer

What is a RoHS Compliance certification?

RoHS, or Restriction of Hazardous Substances, is a directive that originated from the European Union (EU) intending to restrict the use of certain hazardous materials in the manufacturing of electrical and electronic equipment. RoHS Compliance certification is an acknowledgment that a product adheres to the regulations outlined in the RoHS directive. The restricted substances include lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). The certification ensures that a product is free from or within the permissible limits of these hazardous substances, contributing to environmental protection and the reduction of health risks associated with the disposal and use of electronic products.

To achieve RoHS Compliance certification, manufacturers must conduct thorough assessments and testing of their products to confirm compliance with the directive's substance restrictions. Documentation and a declaration of conformity are typically required to demonstrate that the product meets RoHS standards. RoHS Compliance is not only significant for market access in the European Union but has also influenced regulations and practices in other regions globally, emphasizing the importance of environmentally friendly and sustainable manufacturing processes in the electronics industry.

Fig 4. RoH certifications for pressure sensor

What is a UL certification?

UL certification, provided by Underwriters Laboratories, is a widely recognized safety certification that signifies a product's compliance with specific safety standards. UL is an independent organization that evaluates and tests products for safety and performance. Products that undergo UL certification have been rigorously examined by UL engineers and deemed to meet established safety requirements. The UL mark, commonly seen on various products such as electronics, appliances, and industrial equipment, assures consumers, retailers, and regulatory authorities that the product has met stringent safety standards and can be used or sold with confidence.

To obtain UL certification, manufacturers submit their products to UL for testing and evaluation. The process involves a thorough examination of the product's design, materials, and construction, as well as performance testing to ensure it meets safety requirements. UL certification is not mandatory, but many manufacturers opt for it voluntarily to enhance the marketability and credibility of their products. The UL mark is often a key factor in building trust among consumers, as it indicates that the product has undergone comprehensive safety assessments by an independent and reputable organization.

Fig 5. UL marking

What is an ATEX certification?

ATEX certification is a European Union directive that addresses the safety of equipment used in potentially explosive atmospheres. The term "ATEX" is derived from "ATmosphères EXplosibles," indicating environments where flammable gases, vapors, mists, or combustible clouds of dust may be present. The ATEX directive outlines specific requirements for the design, manufacturing, and use of products, including electrical and non-electrical equipment, intended for use in explosive atmospheres. The goal of ATEX certification is to prevent the occurrence of explosions by ensuring that equipment used in such environments meets stringent safety standards.

To achieve ATEX certification, manufacturers must follow a thorough assessment process that involves testing products to verify their compliance with ATEX requirements. The certification covers various aspects, including electrical and mechanical safety, as well as protection against potential ignition sources. ATEX certification is particularly important for industries such as oil and gas, chemical, and mining, where the risk of explosive atmospheres is higher. Products that successfully obtain ATEX certification receive a specific marking indicating their compliance, allowing them to be legally sold and used in potentially hazardous environments within the European Union and other regions that recognize ATEX standards.

Fig 6. ATEX certification

What is an IECEx certification?

IECEx certification, short for the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres, is a global certification scheme for electrical and non-electrical equipment used in explosive atmospheres. Similar to ATEX in Europe, IECEx provides an internationally recognized framework for ensuring the safety and reliability of equipment in environments where there is a risk of explosive gases, vapors, mists, or combustible specks of dust. The certification demonstrates that a product has undergone rigorous testing and meets the requirements of international standards related to explosive atmospheres, promoting safety and preventing the risk of ignition sources in hazardous environments.

To obtain IECEx certification, manufacturers submit their products to accredited testing laboratories that assess them against relevant international standards, such as the IEC 60079 series. The certification covers various aspects, including electrical and mechanical safety, as well as protection against potential sources of ignition. IECEx certification is recognized in many countries, facilitating the global acceptance of equipment certified under this scheme. Industries such as oil and gas, mining, chemical, and manufacturing often require IECEx-certified products to ensure the safety of operations in potentially explosive atmospheres.

Fig 7. IECEx certification

What is an IP Rating?

An IP (Ingress Protection) rating is a standard used to define the level of protection provided by an enclosure against the intrusion of solid objects like dust and liquids such as water. The IP rating is expressed as two numbers, where the first digit indicates the level of protection against solid particles, and the second digit indicates the level of protection against liquids. The higher the numbers, the greater the protection. For example, an IP68 rating means that the product is highly resistant to both dust (6) and water (8), making it suitable for use in challenging environmental conditions.

Understanding the IP rating is crucial in determining the suitability of a product for specific applications and environments. Different industries and applications may require varying levels of protection, and selecting products with appropriate IP ratings ensures that they can withstand the environmental challenges they may encounter. IP-rated products are commonly found in electronics, lighting fixtures, outdoor equipment, and industrial machinery, where protection against dust and moisture is essential for reliable and durable performance.

Fig 8. IP rating

What is an ISO certification?

ISO certification refers to the certification of a company's quality management system according to the standards set by the International Organization for Standardization (ISO). ISO 9001 is one of the most widely recognized ISO standards, focusing on quality management and assurance. Achieving ISO certification involves implementing a set of documented processes and procedures that ensure consistent product or service quality and customer satisfaction. The certification process typically includes a comprehensive audit by an accredited certification body to verify that the organization's quality management system aligns with ISO 9001 requirements. ISO certification is not specific to a particular product but rather confirms that the organization follows international best practices in quality management.

ISO certification provides several benefits for organizations, including enhanced credibility, improved customer confidence, and increased competitiveness. It signals to customers and stakeholders that the company is committed to maintaining high standards in its operations, leading to greater trust and market acceptance. While ISO 9001 is one of the most well-known standards, ISO offers certifications for various aspects such as environmental management (ISO 14001), information security management (ISO 27001), and many others, each addressing specific areas of organizational performance and responsibility.

What are the different types of ISO certification?

There are various ISO certifications, each corresponding to different standards developed by the International Organization for Standardization (ISO). Some of the prominent types of ISO certifications include:

- ISO 9001: Quality Management System (QMS): ISO 9001 sets the standard for quality management systems and applies to any organization, regardless of its size or industry. It focuses on enhancing customer satisfaction through effective quality management practices.

- ISO 14001: Environmental Management System (EMS): ISO 14001 provides a framework for organizations to establish and improve environmental management systems. It addresses the impact of an organization's activities on the environment and promotes sustainable practices.

- ISO 27001: Information Security Management System (ISMS): ISO 27001 outlines requirements for establishing, implementing, maintaining, and continually improving an information security management system. It helps organizations manage and secure their information assets.

- ISO 45001: Occupational Health and Safety Management System (OH&S MS): ISO 45001 focuses on occupational health and safety, providing a framework for organizations to manage risks, prevent work-related injuries and illnesses, and improve overall workplace safety.

- ISO 50001: Energy Management System (EnMS): ISO 50001 is designed to help organizations establish systems and processes to improve energy performance, increase energy efficiency, and reduce energy consumption.

- ISO 22000: Food Safety Management System (FSMS): ISO 22000 sets standards for food safety management, providing a framework to ensure the safety of food products throughout the entire food supply chain.

- ISO 13485: Medical Devices Quality Management System (QMS): ISO 13485 specifies requirements for a quality management system in the design and manufacturing of medical devices. It ensures compliance with regulatory requirements in the medical device industry.

- ISO 9001: Quality Management System (QMS) for Automotive Production and Relevant Service Parts Organizations (IATF 16949): Developed in conjunction with the International Automotive Task Force (IATF), this standard focuses on quality management in the automotive industry.

These are just a few examples, and many other ISO standards address specific aspects of management systems and industry requirements. The choice of ISO certification depends on the organization's objectives, industry, and specific areas it aims to improve or standardize.

Fig 9. ISO certification

What is a NIST certification?

NIST (National Institute of Standards and Technology) does not provide certifications in the traditional sense. However, NIST plays a crucial role in the calibration and standardization of measurement instruments, including those used in pressure sensors, temperature gauges, and other devices. NIST's primary function is to develop and maintain measurement standards, ensuring accuracy, consistency, and reliability in various fields. Laboratories and calibration facilities often use NIST-traceable standards to calibrate their equipment, providing a chain of traceability back to the reference standards maintained by NIST.

When a measurement instrument is said to be "NIST-traceable," it means that its calibration can be traced back to NIST standards through an unbroken chain of comparisons. This traceability provides confidence in the accuracy of measurements made by the instrument. While NIST itself does not issue certifications, the use of NIST-traceable standards is a common practice in various industries to uphold the accuracy and reliability of measurement instruments, contributing to quality assurance and compliance with industry standards.

Fig 10. NIST marking

What is an FDA certification?

The FDA (U.S. Food and Drug Administration) does not issue certifications in the same way some other organizations do; instead, it provides approvals and clearances for certain products and processes. In the context of medical devices, pharmaceuticals, and certain food products, FDA approval or clearance signifies that a product or process meets the regulatory requirements for safety and efficacy in the United States. For medical devices, FDA approval is often required before a product can be marketed and sold in the U.S., and the approval process involves a thorough evaluation of the device's safety and performance.

FDA certifications are particularly crucial in the healthcare and pharmaceutical industries, as they instill confidence in the safety and effectiveness of products. The FDA reviews data from manufacturers to assess the product's design, manufacturing process, and performance through rigorous testing. In the case of pharmaceuticals, FDA approval is required before a new drug can be introduced to the market. The FDA's role is to ensure that products meet the necessary standards to protect public health and safety, and obtaining FDA approval is a significant milestone for companies seeking to bring their products to the U.S. market.

Fig 11. FDA marking

What is an EHEDG?

EHEDG stands for the European Hygienic Engineering & Design Group. It is a consortium of equipment manufacturers, food industries, research institutes, and public health authorities that focuses on promoting hygienic engineering and design in the food, pharmaceutical, and cosmetics industries. EHEDG provides guidelines, standards, and certification for equipment and processes to ensure they meet the highest standards of hygiene and safety in these sensitive industries.

The primary goal of EHEDG is to develop and disseminate hygienic design principles and recommendations to prevent contamination and ensure the safe processing of food and other sensitive products. The group collaborates with industry experts, regulatory bodies, and academia to establish best practices for equipment design, materials, and manufacturing processes. EHEDG certification serves as a mark of compliance with these standards, assuring consumers and industry stakeholders that the equipment meets stringent hygiene and safety requirements in critical sectors where product purity is of utmost importance.

Fig 12. EHEDG certification

Pressure sensor features certifications

ISO certifications are not specifically tied to pressure sensor features; instead, they address broader quality management, environmental management, information security, and other organizational aspects. However, pressure sensors used in specific industries or applications may need to adhere to certain standards to ensure their reliability and safety. Here are some certifications relevant to pressure sensors and their features:

- ATEX Certification: ATEX certification is crucial for pressure sensors used in potentially explosive atmospheres, such as those in oil and gas, chemical, or mining industries.

- IECEx Certification: Similar to ATEX, IECEx certification is relevant for pressure sensors used in explosive atmospheres and ensures compliance with international standards.

- NIST Traceability: While not a certification, NIST traceability is essential for calibration standards, ensuring that pressure sensors provide accurate and traceable measurements.

- CE Marking: CE certification is important for pressure sensors to comply with European Union standards, ensuring their safety and environmental performance.

- UL Certification: UL certification may be relevant for pressure sensors, especially in industrial applications, to demonstrate compliance with safety standards.

While these certifications address specific aspects like safety, environmental protection, and calibration, they may not directly pertain to the inherent features of pressure sensors. Pressure sensor features, such as accuracy, sensitivity, and response time, are often determined and specified by the sensor's design, technology, and intended applications rather than certifications.

A real example of a pressure sensor ISO 9001 in the industry

ISO 9001 certification for a pressure sensor in the industry reflects the adherence of the manufacturer to established quality management standards. Let's consider a hypothetical example:

Company: XYZ Pressure Sensor Manufacturing Co.

Scenario: XYZ Pressure Sensor Manufacturing Co. specializes in producing pressure sensors used in various industrial applications, including manufacturing processes, automotive systems, and aerospace equipment. To enhance its commitment to quality, XYZ sought ISO 9001 certification for its quality management system.

ISO 9001 Implementation: XYZ implemented ISO 9001 standards across its organization. This involved defining and documenting quality management processes, from design and manufacturing to testing and customer support. The company established procedures for traceability, calibration, and quality control throughout the production cycle of its pressure sensors.

Benefits of ISO 9001 Certification:

- Enhanced Quality Management: ISO 9001 certification ensures that XYZ follows best practices in quality management. This involves continuous monitoring, evaluation, and improvement of processes, leading to consistently high-quality pressure sensors.

- Customer Confidence: With ISO 9001 certification, XYZ demonstrates its commitment to delivering reliable and conforming products. This enhances customer confidence in the performance and durability of the pressure sensors, leading to increased customer satisfaction.

- Efficiency and Consistency: ISO 9001 certification encourages efficiency in operations and standardization of processes. This results in consistent production practices, minimizing errors and defects in pressure sensor manufacturing.

- Market Competitiveness: ISO 9001 certification is often a requirement for suppliers in various industries. XYZ's certification enhances its market competitiveness, opening doors to new business opportunities and partnerships.

In this example, ISO 9001 certification for XYZ Pressure Sensor Manufacturing Co. assures customers that the company prioritizes quality throughout its operations. The certification contributes to the company's overall success and competitiveness in the pressure sensor industry.

A real example of pressure sensor SIL (Safety Integrity Level) certification in the industry

Safety Integrity Level (SIL) certifications are typically associated with systems and devices used in safety-critical applications, where failure could lead to serious consequences. While SIL certifications are more commonly associated with complex safety instrumented systems (SIS) rather than individual sensors, pressure sensors used within these systems must often adhere to SIL requirements. Here's a hypothetical example:

Company: ABC Safety Systems Ltd.

Scenario: ABC Safety Systems Ltd. specializes in providing safety solutions for the petrochemical industry. They design safety instrumented systems that include pressure sensors to monitor and control critical processes in refineries.

SIL Certification Implementation: To meet the stringent safety requirements of the petrochemical industry, ABC Safety Systems Ltd. ensures that its pressure sensors comply with Safety Integrity Level standards, such as IEC 61508 or IEC 61511. These standards define SIL levels ranging from SIL 1 (lowest) to SIL 4 (highest), with the level determined by the risk reduction factor needed for a specific application.

ABC Safety Systems Ltd. integrates SIL-certified pressure sensors within its safety instrumented systems, ensuring that these sensors are designed, manufactured, and tested to meet the specified SIL requirements. The sensors are crucial components of the overall safety architecture, providing accurate and reliable data to the safety systems.

Benefits of SIL Certification:

- Risk Mitigation: SIL-certified pressure sensors contribute to the overall risk reduction strategy by providing reliable measurements in critical processes, helping to prevent hazardous events or mitigate their consequences.

- Compliance with Industry Standards: Achieving SIL certification demonstrates ABC Safety Systems Ltd.'s commitment to meeting industry safety standards and regulatory requirements, enhancing the reliability and trustworthiness of their safety instrumented systems.

- Enhanced Safety Performance: SIL-certified pressure sensors contribute to the overall safety performance of the systems in which they are integrated, ensuring a high level of safety integrity to protect personnel, the environment, and assets.

While this example focuses on a broader safety system, it illustrates how pressure sensors within such systems must adhere to SIL certifications to ensure the safety and reliability of critical industrial processes.

What are the benefits of a certificated pressure sensor?

The certification of a pressure sensor, whether it's related to safety standards, environmental compliance, or quality management, offers several benefits. Here are some key advantages:

- Reliability and Accuracy: Certification ensures that the pressure sensor meets specific performance, accuracy, and reliability standards. This is crucial in applications where precise and consistent pressure measurements are essential for properly functioning equipment and processes.

- Compliance with Industry Standards: Certifications such as ATEX, IECEx, CE, or ISO demonstrate that the pressure sensor complies with industry-specific standards and regulations. This is particularly important in sectors such as manufacturing, healthcare, and hazardous environments where adherence to standards is a legal or safety requirement.

- Customer Confidence: Certifications enhance customer confidence in the product's quality and reliability. Knowing that a pressure sensor has undergone testing and meets industry standards gives customers assurance that the product is suitable for their applications and complies with safety and performance requirements.

- Market Access: In many industries, certifications are prerequisites for market access. Having a certificated pressure sensor allows manufacturers to access global markets where adherence to specific standards is mandatory or preferred, facilitating international trade and partnerships.

- Risk Mitigation: Certifications, especially those related to safety and environmental standards, contribute to risk mitigation. For example, in industries where explosive atmospheres are present, ATEX or IECEx certification ensures that pressure sensors are designed to operate safely in such environments, minimizing the risk of explosions.

- Quality Management: Certifications like ISO 9001 demonstrate that the manufacturer has implemented and maintains a robust quality management system. This commitment to quality management can result in improved operational efficiency, better control over manufacturing processes, and ultimately, higher-quality pressure sensors.

- Legal and Regulatory Compliance: Certificated pressure sensors help manufacturers ensure compliance with legal and regulatory requirements. This is particularly important in industries where non-compliance could lead to legal consequences, product recalls, or damage to the company's reputation.

- Facilitation of Purchasing Processes: Many organizations and industries prefer or require certified products. Certifications streamline the purchasing process as they provide a clear indication that the pressure sensor meets specific criteria, reducing the need for extensive evaluation and testing by the end user.

Overall, the benefits of a certificated pressure sensor extend beyond the product itself, positively impacting the manufacturer, the customers, and the industry as a whole.

What are the considerations of a certified pressure sensor?

When considering certified pressure sensors, there are several important factors to take into account to ensure the sensor meets the specific requirements of your application. Here are some key considerations:

- Application Requirements: Clearly define the requirements of your application. Consider the environmental conditions, the pressure range to be measured, the medium (gas or liquid), and any specific safety or regulatory standards applicable to your industry.

- Certification Standards: Identify the relevant certification standards for your industry or application. Common certifications include ATEX, IECEx, CE, UL, ISO, and others. Ensure that the pressure sensor has the appropriate certifications to meet regulatory and safety requirements.

- Accuracy and Precision: Assess the accuracy and precision requirements for your application. Different pressure sensors have varying levels of accuracy, and it's crucial to select one that meets the specific measurement needs of your system.

- Pressure Range: Consider the pressure range that the sensor needs to measure. Some sensors are designed for low-pressure applications, while others are suitable for high-pressure environments. Choose a pressure sensor that aligns with your operational requirements.

- Environmental Conditions: Evaluate the environmental conditions in which the pressure sensor will operate. Consider factors such as temperature, humidity, and exposure to corrosive substances. Ensure that the sensor is designed to withstand the environmental challenges of your application.

- Certification Documents: Request and review the certification documents provided by the sensor manufacturer. This includes certification records, test reports, and other documentation that validate compliance with industry standards. Verify that the certification is current and applicable to your region.

- Calibration and Traceability: Check if the pressure sensor comes with calibration information and traceability to national or international standards. Calibration ensures the accuracy of the sensor's measurements, and traceability provides a clear path to the reference standards used in calibration.

- Reliability and Durability: Assess the reliability and durability of the pressure sensor. Consider the expected lifespan of the sensor and its ability to operate consistently over time in the intended conditions. Look for features such as robust construction and resistance to environmental factors.

- Supplier Reputation: Consider the reputation and track record of the pressure sensor supplier or manufacturer. Established and reputable suppliers are more likely to produce high-quality, certificated sensors that meet industry standards.

- Cost: While certification adds value to a pressure sensor, it's essential to balance this with your budget constraints. Compare the cost of the certified sensor with its features and benefits to ensure that it provides the best value for your specific application.

By carefully considering these factors, you can select a certified pressure sensor that aligns with the requirements of your application, meets industry standards, and ensures reliable and accurate pressure measurements.

What happens if a pressure sensor is not certificated?

If a pressure sensor is not certified, it can have several potential consequences, depending on the industry and application. Here are some key considerations:

- Regulatory Compliance Issues: In certain industries, regulatory bodies, and standards organizations may require the use of certified pressure sensors to ensure safety, environmental compliance, and quality. If a sensor lacks the necessary certifications, it may lead to regulatory non-compliance, exposing the user or manufacturer to legal consequences, fines, or restrictions on product distribution.

- Safety Risks: Certified pressure sensors, especially those with safety-related certifications (such as ATEX or IECEx), are designed to operate safely in specific environments, including those with potentially explosive atmospheres. Using a non-certified sensor in such environments could pose safety risks, increasing the likelihood of accidents or hazardous incidents.

- Quality and Reliability Concerns: Certifications often serve as indicators of a product's quality and reliability. The lack of certification may suggest that the sensor has yet to undergo rigorous testing for specific performance standards. This could result in issues related to accuracy, repeatability, and overall reliability of pressure measurements.

- Market Access Limitations: In some industries and markets, certified products are preferred or required. Without certifications, a pressure sensor may face limitations in market access, hindering its acceptance by potential customers or regulatory bodies. Many industries prioritize the use of certified equipment to ensure consistent and standardized performance.

- Customer Confidence: Certified pressure sensors provide customers with confidence in the product's performance and compliance with industry standards. Lack of certification may lead to reduced confidence among potential users, affecting the sensor's market acceptance and trustworthiness.

- Product Liability Concerns: In the event of a failure or malfunction of a pressure sensor that lacks certifications, liability issues may arise. Certification provides a level of assurance regarding the sensor's design, manufacturing, and performance standards. Without certification, there may be an increased risk of product liability claims.

- Operational Challenges: In certain industries, certification may be a requirement for participation in specific projects or collaborations. Without the necessary certifications, a pressure sensor may be excluded from opportunities where compliance with standards is a prerequisite.

It's important to note that the significance of certification varies depending on the specific industry, application, and regulatory environment. In some cases, certification is mandatory, while in others, it may be preferred or recommended. Users should carefully assess their requirements and choose pressure sensors that meet the relevant standards and certifications for their specific use cases.

What are the Ship Approvals?

Ship approvals refer to certifications, authorizations, or approvals granted by regulatory bodies, classification societies, or maritime organizations to ensure that a ship, its components, and associated systems comply with established standards, rules, and safety requirements. These approvals are crucial for ensuring ships' seaworthiness, safety, and environmental compliance. Several types of ship approvals exist, and they can cover various aspects of a vessel's design, construction, and operation. Some common ship approvals include:

- Classification Society Approval: Ships are often classed by classification societies, such as Lloyd's Register, American Bureau of Shipping (ABS), DNV GL, Bureau Veritas, or others. These societies provide approvals based on design reviews, surveys, and inspections throughout a ship's lifecycle. Classification ensures that the ship meets specified standards for structural integrity, stability, safety, and environmental performance.

- Flag State Approval: Each ship operates under the authority of a flag state, which is responsible for ensuring that the vessel complies with its regulations and international conventions. Flag state approvals involve certifications related to the ship's registration, documentation, and adherence to national and international maritime laws.

- International Maritime Organization (IMO) Compliance: The IMO sets international standards and regulations for the safety, security, and environmental performance of international shipping. Ships must obtain approvals related to IMO conventions, such as the International Convention for the Safety of Life at Sea (SOLAS), the International Convention for the Prevention of Pollution from Ships (MARPOL), and others.

- Safety Equipment Approvals: Ships must have various safety equipment, such as life-saving appliances, fire-fighting equipment, and navigation aids. Approvals for these items ensure that they meet relevant international standards and are suitable for use in maritime emergencies.

- Environmental Certifications: Ships must comply with environmental regulations to minimize their impact on the marine environment. Approvals may cover ballast water management systems, exhaust gas cleaning systems (scrubbers), and other technologies that help reduce pollution and comply with international environmental standards.

- Radio and Communication Approvals: Shipboard communication equipment, including radio systems and satellite communication devices, must be approved by relevant authorities to ensure proper functionality and compliance with international regulations, such as those outlined by the International Telecommunication Union (ITU).

- Safety Management System (SMS) Certification: Ships are often required to implement a Safety Management System, which is subject to certification by classification societies or flag states. The SMS outlines procedures and practices to ensure the safety of the ship and its crew.

Ship approvals are essential to ensure that vessels are designed, built, and operated in a manner that prioritizes safety, environmental protection, and adherence to international regulations. They play a crucial role in the maritime industry, contributing to the overall safety and sustainability of global shipping operations.

DNV (Det Norske Veritas)

DNV stands for Det Norske Veritas. DNV is a global quality assurance and risk management company that provides services for industries such as maritime, oil and gas, energy, and healthcare. In 2013, DNV merged with Germanischer Lloyd to form DNV GL, but in 2020, the company decided to return to the original name, DNV, following the sale of its oil and gas division.

DNV offers a wide range of services, including the classification of ships and offshore structures, certification of management systems, risk management, and technical advisory services. As a classification society, DNV sets standards for the design, construction, and operation of ships and offshore structures, ensuring their safety, environmental performance, and reliability. In addition to maritime services, DNV provides certification and advisory services to help organizations manage risk, enhance safety, and achieve compliance with industry standards in various sectors.

Fig 13. DNV approval

LRS (Lloyd’s Register of Shipping)

LRS, the ship classification institute of England, is a technical and commercial services organization and a maritime rating association wholly owned by the Lloyd’s Register Foundation, a British charity dedicated to research and development in science and engineering. The stated goals of this organization are classification, compliance, and consultancy services to the marine and offshore industries and to increase the safety of life, property, and the environment by assessing and certifying ships, systems, and facilities to help shipowners, operators, and builders (through accreditation, certification, and accreditation) to ensure the quality of design, construction, production and operation of their critical infrastructure and assets to the highest levels of safety and performance.LRS rules and regulations for the classification of ships ensure that all registered vessels are safely operated within the laws of the relevant nations.

Fig 14. LRS marking

BV (Bureau Veritas)

Bureau Veritas is a global leader in laboratory testing, inspection, and certification providing high-quality services. Bureau Veritas helps its clients improve their performance by delivering services and innovative solutions to ensure that their assets, products, infrastructure, and processes meet standards, regulations, and the growing challenges of quality, health and safety, environmental protection, and social responsibility. Also, it provides information for clients that enables them to evaluate the reliability of ships and equipment and to confirm the protection of people and property.

ABS (American Bureau of Shipping)

ABS is one of the world’s leading ship classification societies that has been committed to establishing standards for safety and excellence and classification, technical, and regulatory services to help and advance the marine and offshore energy industries. It confirms that marine vessels and offshore structures such as all materials, equipment, and machinery comply with safety rules, guides, standards, and other criteria that the organization has established for design, construction, and periodic surveys to promote their safe design and assembly. ABS works with the marine industry throughout the world as it creates new technologies for constructing marine vessels and offshore structures, revising and updating its certifications to fulfill the changing industry needs.

GL (Germanischer Lloyd)

GL, another pure ship classification society, and maritime and corporate service is known as a leading player in maritime risk assessment and certification. It ensures that new buildings and constructions, existing fleets, shipyards, and port facilities comply with international regulations, recognized standards, and rules on security, safety, quality, performance, seafarers' operation, and living conditions as well as environmental issues. GL provides sophisticated technical services available for all safety and risk issues of installations related to energy production, storage, and transportation.

NKK (Nippon Kaiji Kyokai)

Nippon Kaiji Kyokai, known as ClassNK or often in the industry as just “NK”, is an international ship classification society and an accredited certification body dedicated to safer, cleaner seas. NK is actively participating in a growing range of ship-related activities and services intending to contribute to promoting the protection of human life and property at sea and also the protection of the marine environment. Its responsibility is to ensure that new buildings and existing ships are compliant with the rules and standards that it has developed to ensure their safety.

Fig 15. NKK shipping

RS (Russian Maritime Register of Shipping)

RS is a leading global classification society closely engaged in ice ships, high-tech icebreakers, and ice-resistant equipment to promote offshore oil and gas fields. Its goal is to provide standards that ensure the safety of life at sea, the safety of navigation, the safe carriage of goods by sea and in inland waters, minimizing the negative impact of human activities on the environment, and preventing environmental pollution through based risk assessment and risk management procedures.

CCS (China Classification Society)

CSS is a professional,world-leading certification and non-profit-making body that provides classification services. The target of this ship technical inspection agency is to present legal services and technical specifications and standards for the shipping, shipbuilding, offshore development, and related manufacturing industries and maritime insurance for the enhancing and safeguarding of the safety of life and property at sea and for the prevention of pollution and contamination to the environment of the ocean. CSS not only had activities in the field of ships but also provided services in renewable energy, transportation, infrastructure, and large steel structures.

KR (Korean Register of Shipping)

KR is an internationally recognized not-for-profit ship classification society aimed at promoting safe ships and clean oceans by continually providing technology and human resources related to shipping, shipbuilding, and other industrial services. This world-leading organization offers technical advice to the maritime industry to ensure the safeguards of life, property, and the environment through the promotion of excellence in its regulations and standards. KR offers a range of certification services to help users register their vessels and work them in a safe and responsible channel in their service life. You can see our selection of pressure sensors by clicking here.

RINA (Registro Italiano Navale)

RINA is a multinational Italian classification society involved in the maritime transport sector. It developed its services in the field of classification, certification, testing, and inspection across maritime, energy, industrial, rail, transport, environmental, and other fields. RINA services in the assessment, control, certification, and research comply with national and international rules and standards to cover risks related to lose or damage of the body and rigging of sailing ships and meet the needs of maritime operators.

Conclusion

In conclusion, certifications play a vital role across various industries, ensuring that products, processes, and systems meet established standards and requirements. Certifications such as ISO, ATEX, IECEx, CE, UL, and others assure quality, safety, and compliance with industry-specific regulations. For pressure sensors, certifications validate their accuracy, reliability, and suitability for use in specific environments, including hazardous ones.

Certifications contribute to customer confidence, market access, and regulatory compliance. They demonstrate a commitment to best practices, environmental responsibility, and the highest standards of quality management. In industries like healthcare, manufacturing, and hazardous environments, certified pressure sensors are essential components that contribute to the overall safety and efficiency of systems and processes.

However, the absence of certifications can have significant repercussions, including regulatory non-compliance, safety risks, and limitations in market access. Choosing certified pressure sensors ensures that they have undergone rigorous testing and adhere to industry standards, mitigating potential risks and enhancing the overall reliability of pressure measurement systems.

Ultimately, the consideration and acquisition of certified pressure sensors align with broader trends in industries that prioritize quality, safety, and adherence to regulatory frameworks. As technology advances and industries evolve, certifications will continue to be instrumental in maintaining and enhancing the integrity and performance of various products and systems.

To recap

- What is performance certification? Performance certification involves assessing and validating a product's ability to meet specific performance criteria, ensuring it performs as intended under various conditions. It often includes testing and evaluation to confirm characteristics like accuracy, reliability, and functionality.

- Why is performance certification important? Performance certification is crucial for ensuring that products meet quality and safety standards. It provides confidence to consumers, regulatory bodies, and stakeholders that a product performs reliably and consistently, meeting or exceeding specified criteria.

- What types of products typically undergo performance certification? Various products, including electronic devices, machinery, medical equipment, and sensors, can undergo performance certification. The specific type of certification depends on the industry and the product's intended use.

- How is performance certification different from product testing? While product testing is part of the certification process, performance certification involves a broader assessment of a product's overall performance, including its adherence to industry standards and specifications beyond individual tests.

- Who provides performance certification? Certification can be provided by accredited third-party testing laboratories, certification bodies, or regulatory agencies depending on the industry and the standards applicable to the product.

- What is the role of standards in performance certification? Standards serve as benchmarks for product performance. Performance certification often involves testing against specific standards relevant to the industry or product category.

- How can a company prepare for performance certification? Companies can prepare for performance certification by thoroughly understanding the applicable standards, conducting internal testing, addressing potential issues, and engaging with certification bodies or testing laboratories.

- What is the significance of third-party certification? Third-party certification adds credibility as it involves an independent assessment by an unbiased entity. This ensures that the evaluation is objective and meets industry standards.

- Can a product be sold without performance certification? In many industries, especially those with regulatory requirements, selling a product without performance certification may be challenging or even prohibited. Certification often serves as a prerequisite for market access.

- How long does it take to obtain performance certification? The time required for performance certification varies based on factors such as the complexity of the product, the industry, and the specific certification process. It can range from weeks to several months.

- What is the difference between product certification and system certification? Product certification focuses on individual products, while system certification involves certifying an entire system or process. System certification is often relevant in industries where the interaction of multiple components is critical.

- Is performance certification a one-time process? While the initial certification is conducted before a product is introduced to the market, ongoing monitoring and periodic recertification may be required to ensure continued compliance, especially if there are updates or changes to the product.

- How does international certification differ from local certification? International certification often involves adherence to globally recognized standards, allowing products to be marketed internationally. Local certification may be specific to regional standards and regulations.

- Can a product lose its performance certification? Yes, a product can lose its certification if it no longer meets the required standards or if changes are made to the product without obtaining re-certification.

- How can consumers verify if a product has performance certification? Consumers can check product documentation, labels, or the manufacturer's website for certification marks, such as CE, UL, or other relevant symbols, and verify the product's certification status through certification body databases if available.

References

http://www.pressuresensorsuppliers.com/about-36.html

https://www.microsensorcorp.com/Details_FAQs-about-Micro-Sensor-Certificates-and-Approvals.html

https://www.viatran.com/product/model-24a-pressure-transducer

https://marks.ul.com/about/ul-listing-and-classification-marks/

https://www.stssensors.com/products/gp-sts-pressure-2/pressure-sensors-atex-iecex/atm_1st_ex/

https://blog.wika.com/products/pressure-products/marking-pressure-sensors-atex/

https://www.firgelliauto.com/en-nl/blogs/actuators/your-complete-guide-to-ip-ratings

https://monarchinstrument.com/products/cal-nist-for-dc1250

https://ossmideast.com/fda-registration-service/

https://www.smcworld.com/newproducts/en-jp/21/kfg2/

https://www.dco.uscg.mil/acp/DNV/

https://www.forepaas.com/en/blog/classnk-optimizes-ship-inspections/

Recent Posts

-

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025 -

Single-Stage, Multi-Stage, and Variable Speed Booster Pumps: Which One is Right for You?

1. Introduction Is your shower lacking the invigorating pressure you crave? Do your faucets tri …13th Apr 2025 -

Process Connection Unveiled: Decoding the Art of Pressure Sensor Fittings

Process Connection or Fitting of a Pressure Transmitter The process connection or fitting of a …5th Apr 2025