The Ultimate Showdown: Load Cell Comparison Demystified

Welcome to the Load Cell Comparison Guide! If you're looking for a clear and concise way to understand the different types of load cells and their features, you've come to the right place. Load cells are essential devices used for measuring and monitoring forces and loads in various applications, ranging from industrial weighing systems to material testing.

In this guide, we will provide you with a simplified and easy-to-understand comparison of different load cell types, including strain gauge, hydraulic, pneumatic, capacitive, piezoelectric, and magnetic load cells. We'll explore their unique characteristics, working principles, advantages, and disadvantages.

By examining these load cell types side by side, you'll gain a deeper understanding of their respective strengths and limitations. Whether you're interested in accuracy, range, environmental adaptability, or other specific factors, this comparison guide will help you make informed decisions and choose the right load cell for your application.

We'll break down the technical jargon and present the information in a user-friendly format, allowing you to grasp the key differences and make meaningful comparisons. Whether you're new to load cells or have some prior knowledge, this guide aims to simplify the complexities and help you navigate the world of load cell technology with ease.

So, let's embark on this load cell comparison journey together and discover the ideal load cell for your specific needs. With this knowledge in hand, you'll be equipped to make well-informed decisions and select the perfect load cell that meets your requirements for precision, reliability, and performance.

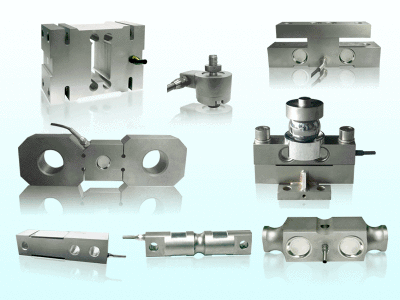

Fig 1. Load cell types

Load Cell Types Comparison

| Load Cell Type | Working Principle | Measurement Range | Accuracy | Environmental Sensitivity | Cost |

| Strain Gauge | Deformation of Strain Gauges | Low to High Loads | High | Sensitive to Temperature | Moderate |

| Hydraulic | Fluid Pressure | High Loads | High | Susceptible to Fluid Leaks | High |

| Pneumatic | Air Pressure | Low to Medium Loads | Medium to High | Susceptible to Air Leaks | Moderate |

| Capacitive | Capacitance Variation | Low to Medium Loads | High | Sensitive to Temperature | Moderate |

| Piezoelectric | Piezoelectric Effect | Low to High Loads | High | Sensitive to Temperature | High |

| Magnetic | Magnetic Field Variation | Low to High Loads | High | Sensitive to Magnetic Fields | High |

Please note that the information provided in the table is a general overview and may not capture all the nuances and variations within each type of load cell. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's always recommended to consult with load cell manufacturers or experts to select the most suitable load cell for your specific application.

Comparing all types of Strain Gauge

Certainly! Here's a table comparing different types of strain gauge load cells based on various factors:

| Strain Gauge Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Bending Beam Load Cell | Single or multiple | Moderate to High | Moderate to High | Moderate |

| S-Type Load Cell | S-shaped configuration | High | Moderate | Moderate |

| Shear Beam Load Cell | Rectangular or T-shaped | High | Moderate to High | Moderate |

| Compression Load Cell | Cylinder or disc shape | High | Moderate to High | Moderate |

| Pancake Load Cell | Flat, disc-like shape | High | Moderate to High | Moderate |

Please note that this table provides a general overview and may not capture all the variations within each strain gauge load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable strain gauge load cell for your specific application.

Comparing all types of Hydraulic load cells

Here's a table comparing different types of hydraulic load cells based on various factors:

| Hydraulic Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Bourdon Tube Load Cell | C-shaped tube | Low to Moderate | Low to Moderate | Moderate |

| Diaphragm Load Cell | Diaphragm | Low to Moderate | Low to Moderate | Moderate |

| Piston Load Cell | Piston and cylinder | Moderate to High | Low to Moderate | High |

| Ring Type Load Cell | Ring | High | Low to Moderate | High |

| Bellows Type Load Cell | Bellows | Moderate to High | Low to Moderate | High |

| Flange Type Load Cell | Flange | High | Low to Moderate | High |

Please note that this table provides a general overview and may not capture all the variations within each hydraulic load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable hydraulic load cell for your specific application.

Comparing all types of Pneumatic load cells

Here's a table comparing different types of pneumatic load cells based on various factors:

| Pneumatic Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Diaphragm Load Cell | Diaphragm | Low to Moderate | Low to Moderate | Moderate |

| Piston Load Cell | Piston and cylinder | Moderate to High | Low to Moderate | High |

| Bellows Type Load Cell | Bellows | Moderate to High | Low to Moderate | High |

| Air Bag Load Cell | Airbag | Low to Moderate | Moderate to High | Moderate |

| Differential Pressure Cell | Pressure difference | Low to Moderate | Low to Moderate | Moderate |

Please note that this table provides a general overview and may not capture all the variations within each pneumatic load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable pneumatic load cell for your specific application.

Comparing all types of Capacitive load cells

Here's a table comparing different types of capacitive load cells based on various factors:

| Capacitive Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Parallel Plate Load Cell | Parallel plates | Low to Moderate | Low to Moderate | Moderate |

| Interdigitated Load Cell | Interdigitated | Moderate to High | Low to Moderate | High |

| Torsional Load Cell | Torsion elements | Moderate to High | Low to Moderate | High |

| Multi-Axis Load Cell | Multiple sensing elements | High | Low to Moderate | High |

| Single Point Load Cell | Single point | High | Low to Moderate | Moderate |

Please note that this table provides a general overview and may not capture all the variations within each capacitive load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable capacitive load cell for your specific application.

Comparing all types of Piezoelectric load cells

Here's a table comparing different types of piezoelectric load cells based on various factors:

| Piezoelectric Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Quartz Load Cell | Quartz crystal | Low to Moderate | Low to Moderate | High |

| Ceramic Load Cell | Ceramic material | Low to Moderate | Low to Moderate | Moderate |

| Polymer Load Cell | Polymer material | Low to Moderate | Low to Moderate | Low |

| Single Crystal Load Cell | Single crystal | Moderate to High | Low to Moderate | High |

| Thin Film Load Cell | Thin film material | Low to Moderate | Low to Moderate | Moderate |

Please note that this table provides a general overview and may not capture all the variations within each piezoelectric load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable piezoelectric load cell for your specific application.

Comparing all types of Magnetic load cells in a table

Here's a table comparing different types of magnetic load cells based on various factors:

| Magnetic Load Cell Type | Construction | Sensitivity to Load Direction | Temperature Sensitivity | Cost |

| Magnetic Proximity Load Cell | Proximity sensors | Low to Moderate | Low to Moderate | Low |

| Hall Effect Load Cell | Hall effect sensor | Low to Moderate | Low to Moderate | Low to Moderate |

| Magnetoresistive Load Cell | Magnetoresistive | Moderate to High | Low to Moderate | Moderate |

| Magnetostrictive Load Cell | Magnetostrictive | Moderate to High | Low to Moderate | High |

Please note that this table provides a general overview and may not capture all the variations within each magnetic load cell type. The specifications and performance characteristics can vary depending on the specific model and manufacturer. It's recommended to consult with load cell manufacturers or experts to select the most suitable magnetic load cell for your specific application.

Comparing all types of load cells in a table based on their applications

Here's a table comparing different types of load cells based on their applications:

| Load Cell Type | Applications |

| Strain Gauge | Weighing scales, force measurement in manufacturing |

| Hydraulic | Heavy machinery, industrial weighing |

| Pneumatic | Process control, automotive testing |

| Capacitive | Aerospace, robotics, material testing |

| Piezoelectric | Dynamic force measurement, impact testing |

| Magnetic | Crane scales, tension measurement |

| Pneumatic | Material handling, automation, assembly lines |

| Capacitive | Pharmaceutical, food processing, packaging |

| Piezoelectric | Aerospace, automotive crash testing, vibration analysis |

| Magnetic | Heavy-duty industrial applications, off-road vehicles |

Please note that this table provides a general overview of common applications for each type of load cell. The actual range of applications can vary depending on specific models, designs, and industry requirements. It's recommended to consult with load cell manufacturers or experts to select the most suitable load cell for your specific application.

Comparing all types of load cells in a table based on their advantages

Here's a table comparing different types of load cells based on their advantages:

| Load Cell Type | Advantages |

| Strain Gauge | High accuracy, wide measurement range, cost-effective, compatibility with various applications |

| Hydraulic | High load capacity, rugged construction, suitable for high-pressure environments |

| Pneumatic | Fast response, low cost, suitable for dynamic and rapid force measurement |

| Capacitive | High accuracy, low power consumption, resistance to electromagnetic interference |

| Piezoelectric | High sensitivity, wide frequency response, compact size, suitable for dynamic force measurement |

| Magnetic | Non-contact measurement, high durability, resistance to dirt and contaminants |

Please note that the advantages listed above are general characteristics and may not apply to all load cell models within each type. The selection of a load cell should consider the specific requirements of your application. It's recommended to consult with load cell manufacturers or experts to determine the most suitable load cell based on your needs.

Comparing all types of load cells in a table based on their disadvantages

Here's a table comparing different types of load cells based on their disadvantages:

| Load Cell Type | Disadvantages |

| Strain Gauge | Sensitivity to temperature changes, susceptibility to electrical noise |

| Hydraulic | Potential for fluid leaks, bulkier size, and weight, limited measurement range |

| Pneumatic | Susceptibility to air leaks, lower accuracy compared to other types, limited load capacity |

| Capacitive | Sensitivity to temperature changes, vulnerability to humidity and moisture |

| Piezoelectric | Temperature sensitivity, limited overload capacity, and higher cost compared to other types |

| Magnetic | Sensitivity to external magnetic fields, limited measurement range, the higher cost compared to other types |

Please note that the disadvantages listed above are general considerations and may not apply to all load cell models within each class. The selection of a load cell should consider the specific requirements and constraints of your application. It's recommended to consult with load cell manufacturers or experts to determine the most suitable load cell based on your needs.

Sorting the most helpful type of load cell to the least one

Determining the usefulness of a load cell depends on the specific application and requirements. However, here's a subjective ranking of load cell types based on their versatility, widespread use, and overall performance across different applications:

- Strain Gauge Load Cells: Strain gauge load cells are widely used due to their high accuracy, wide measurement range, and compatibility with various applications. They are cost-effective and offer good performance in many weighing and force measurement scenarios.

- Hydraulic Load Cells: Hydraulic load cells excel in high-load capacity applications and harsh environments. They are known for their rugged construction and reliability, making them suitable for heavy machinery and industrial weighing.

- Capacitive Load Cells: Capacitive load cells offer high accuracy, low power consumption, and resistance to electromagnetic interference. They are commonly used in aerospace, robotics, and material testing applications where precise measurements are required.

- Piezoelectric Load Cells: Piezoelectric load cells provide high sensitivity and wide frequency response, making them suitable for dynamic force measurement tasks. They find applications in aerospace, automotive crash testing, and vibration analysis.

- Magnetic Load Cells: Magnetic load cells offer non-contact measurement and high durability. They are commonly used in heavy-duty industrial applications and off-road vehicles where resistance to dirt and contaminants is crucial.

- Pneumatic Load Cells: Pneumatic load cells have fast response times and are cost-effective. They find applications in process control, automotive testing, and material handling, where dynamic and rapid force measurement is required.

Please note that this ranking is subjective and based on general considerations. The most suitable load cell type for a specific application should be determined based on the specific requirements, environmental conditions, and constraints of the application. It is recommended to consult with load cell manufacturers or experts to select the most appropriate load cell for your specific needs.

Conclusion

In conclusion, the load cell comparison table provides a comprehensive overview of various load cell types, their applications, advantages, and disadvantages. By examining the different load cell types side by side, we can draw meaningful comparisons and understand the unique characteristics of each type.

The comparison table highlights key parameters such as measurement range, accuracy, sensitivity, environmental considerations, and suitability for specific applications. This allows users to assess the strengths and limitations of each load cell type and make informed decisions based on their specific requirements.

The table provides a valuable reference for professionals and enthusiasts in fields such as weighing systems, material testing, industrial automation, and more. It serves as a quick and convenient resource for understanding the differences between load cell types and selecting the most suitable option for a given application.

It is important to note that while the comparison table provides a general overview, individual load cell models and manufacturers may have unique specifications and features. It is always recommended to consult with experts or manufacturers for detailed information and guidance when selecting a load cell.

By utilizing the load cell comparison table, users can save time and effort in researching and comparing load cell options. This empowers them to make well-informed decisions and choose the load cell type that best meets their specific needs, ensuring accurate and reliable measurements in their applications.

References

Recent Posts

-

Submersible vs. Jet Pumps: The Ultimate Guide to Deep Well Solutions in Dubai

1. The Importance of Efficient Water Pumps for Homes, Agriculture, and Businesses in DubaiThis post …25th Nov 2024 -

Mastering Water Pump Care in Dubai: Installation, Maintenance, Repair, and Efficiency Tips

I. IntroductionWhy Water Pumps Matter for Dubai HomesIn Dubai’s arid environment, water pumps are es …21st Nov 2024 -

How to Choose and Purchase the Right Water Pump in 2025: A Complete Guide for Dubai Homes

1. IntroductionIn 2025, water pumps have become an integral part of many homes in Dubai, ensuring a …14th Nov 2024