Why a Fiber Optic Cable Outshines Copper: Shedding Light on Superior Connectivity

In today's rapidly evolving world of communication and connectivity, the choice between fiber optic cables and traditional copper cables can make all the difference. Welcome to a comprehensive exploration of these two giants in data transmission. Prepare to uncover the captivating realm of fiber optics, where beams of light carry information at lightning-fast speeds, enabling seamless communication across vast distances. Discover how fiber optic cables revolutionize the way we connect, offering unparalleled bandwidth, enhanced security, and immunity to electromagnetic interference. Get ready to bid farewell to the limitations of copper as we delve into the exciting realm of fiber optics, where the future of high-speed, reliable, and efficient data transmission awaits.

Fig 1. Fiber optic cables

History of Fiber optic cable

The history of fiber optic cable dates back several decades. Here's a summary of the key milestones in its development:

- Early Concepts (the 1840s-1870s): The concept of transmitting light through flexible transparent fibers was proposed by various scientists, including Daniel Colladon and Jacques Babinet. They demonstrated the principle of total internal reflection, which forms the basis of modern fiber optic transmission.

- Optical Telegraph (1880s-1920s): Alexander Graham Bell and his assistant, Charles Sumner Tainter, developed a device called the Photophone in 1880. It used a beam of light to transmit sound signals wirelessly. While not a fiber optic cable per se, the Photophone demonstrated the transmission of sound via light, which laid the foundation for future advancements.

- Fiber Optic Waveguides (1950s-1960s): In the 1950s, researchers began experimenting with fiber optic waveguides made of glass or plastic. These early fibers had high losses and were not suitable for practical use. However, in the 1960s, Corning Glass Works (now Corning Incorporated) developed low-loss glass fibers, known as low-loss optical fibers (LLF), which were a significant breakthrough.

- First Practical Fiber Optic Cable (1970s): In 1970, researchers at Corning produced a practical fiber optic cable that had a loss of about 20 decibels per kilometer (dB/km). This level of loss was a significant improvement over previous fibers and made fiber optic communication systems commercially viable.

- Deployment of Fiber Optic Systems (1970s-1980s): The 1970s and 1980s saw the deployment of early fiber optic communication systems. These systems primarily focused on long-distance applications, such as undersea cables and telephone trunk lines. For example, the first transatlantic fiber optic cable, known as TAT-8, was laid in 1988, providing high-capacity telecommunications between Europe and North America.

- Advancements in Fiber Optic Technology (1980s-1990s): During this period, various advancements were made in fiber optic technology. The introduction of erbium-doped fiber amplifiers (EDFAs) in the 1980s allowed for long-distance signal amplification without the need for costly and complex regenerator stations. Additionally, the development of wavelength-division multiplexing (WDM) enabled multiple signals to be transmitted simultaneously over a single fiber, significantly increasing capacity.

- Fiber to the Home (FTTH) and Broadband Internet (2000s-Present): The 2000s marked the widespread deployment of fiber optic cables for high-speed internet access. Fiber to the Home (FTTH) networks became increasingly popular, offering faster and more reliable connections to residential and commercial areas. This expansion of fiber optic infrastructure continues today, with ongoing efforts to improve speeds and connectivity.

Over time, advancements in fiber optic cable technology have led to higher transmission speeds, longer distances, and increased reliability. Fiber optics have revolutionized the telecommunications industry, enabling the rapid growth of global communication networks and supporting the increasing demand for data transmission in various sectors.

Fiber optic cables

Fiber optic cable is a type of high-speed data transmission medium that uses thin strands of glass or plastic fibers to transmit digital information. It is widely used in telecommunications and computer networking to transmit data over long distances at incredibly high speeds.

Here are some key points about fiber optic cables:

- Structure: Fiber optic cables consist of several components. The core is the central part through which light signals travel. It is surrounded by a cladding layer that reflects the light into the core, preventing signal loss. The cladding is further protected by an outer jacket or coating, which provides mechanical strength and insulation.

- Light transmission: Fiber optic cables transmit data in the form of light pulses. These pulses are generated by light sources such as lasers or light-emitting diodes (LEDs) and are guided through the core of the fiber. The principle behind this transmission is total internal reflection, where light traveling within the core is reflected into the core when it encounters the cladding.

- Advantages: Fiber optic cables offer several advantages over traditional copper cables. They have much higher bandwidth capacity, meaning they can transmit more data over longer distances without degradation. Fiber optic cables are also immune to electromagnetic interference and have a lower signal loss, allowing for more reliable and faster data transmission.

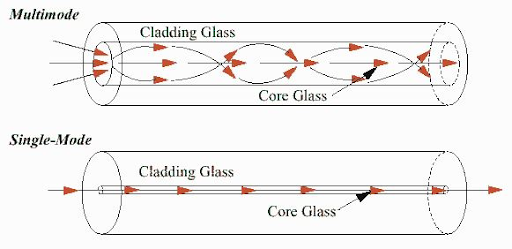

- Types of fiber: There are two main types of fiber optic cables: single-mode fiber (SMF) and multi-mode fiber (MMF). Single-mode fiber has a smaller core and is used for long-distance transmissions, while multi-mode fiber has a larger core and is suitable for shorter distances.

- Applications: Fiber optic cables are extensively used in various industries. They form the backbone of global telecommunications networks, enabling long-distance and high-speed internet connections. They are also used for interconnecting computer networks, and data centers, and for transmitting audio and video signals in cable television systems. Additionally, fiber optic cables are used in medical imaging, military communications, and industrial applications.

- Installation: Installing fiber optic cables requires specialized equipment and expertise. The cables need to be carefully handled to avoid damage and connected using precise techniques, such as fusion splicing or mechanical connectors. Once installed, fiber optic cables can be bundled together in protective conduits or buried underground for added protection.

Fiber optic technology continues to advance, enabling even faster data transmission speeds and increased capacity. It plays a crucial role in supporting our increasingly interconnected world, powering our communication networks, and facilitating the transfer of vast amounts of data quickly and reliably.

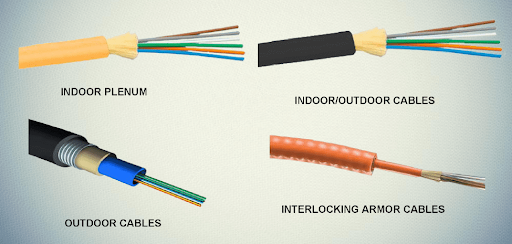

Fig 2. Indoor/outdoor cables

Size of Fiber optic cable table

The size of fiber optic cables can vary depending on their specific design and application. Here's a table comparing some common sizes of fiber optic cables:

Table 1. Fiber optic cable size

| Fiber Optic Cable Size | Diameter (mm) | Typical Application |

| Ultra-Thin Fiber | 0.125 | Medical and surgical applications |

| Simplex Fiber | 0.9 | Single-fiber connections |

| Distribution Fiber | 2.0 | Indoor/outdoor cabling, short distances |

| Tight-Buffered Fiber | 2.4 | Premises cabling, patch cords |

| Loose-Tube Fiber | 2.9 - 3.8 | Outdoor, long-distance, harsh environments |

| Ribbon Fiber | Varies | High-density applications, data centers |

| Armored Fiber | Varies | Harsh environments, rodent protection |

| Composite Fiber Cable | Varies | Multiple fibers in a single cable |

It's important to note that the diameter provided is a general indication, and actual fiber optic cable sizes can vary depending on factors such as the number of fibers within the cable, the presence of protective layers, and the specific manufacturer's design. Additionally, different cable designs may have different specifications and requirements.

What is fiber optic cable made of?

Fiber optic cables are primarily made of two main components: the optical fibers and the protective outer layer.

- Optical Fibers: The core component of a fiber optic cable is the optical fiber itself. Optical fibers are made of either glass or plastic materials. Glass fibers are more commonly used due to their superior performance. The optical fiber consists of a thin strand or filament of glass, which serves as the medium for transmitting light signals.

- Protective Outer Layer: Surrounding the optical fibers is a protective outer layer or coating, known as the cable jacket. The jacket provides mechanical strength, insulation, and protection for the delicate fibers. The jacket is typically made of materials such as polyethylene (PE), polyvinyl chloride (PVC), or low smoke zero halogens (LSZH) compounds. The specific material used depends on the intended application and environmental conditions.

Inside the cable, the optical fibers may be further protected by additional layers, such as buffer coatings or strength members, to enhance durability and tensile strength. These additional layers vary depending on the cable design and intended application.

It's important to note that the actual composition and construction of fiber optic cables can vary among manufacturers and different cable types. The choice of materials and design considerations are crucial to ensure optimal performance and protection of the optical fibers within the cable.

Fig 3. Direct buried cables

What is the speed of fiber optic cable?

Fiber optic cables can transmit data at extremely high speeds. The speed of fiber optic cable depends on various factors, including the type of fiber and the technology used for transmitting and receiving the signals. Here are the typical speeds associated with fiber optic cables:

- Single-Mode Fiber (SMF): Single-mode fiber is designed for long-distance transmission and offers the highest speeds. It can achieve data rates of up to 100 Gbps (Gigabits per second) and beyond. With advanced technologies like Dense Wavelength Division Multiplexing (DWDM) and Coarse Wavelength Division Multiplexing (CWDM), data rates of terabits per second (Tbps) are achievable over long distances.

- Multi-Mode Fiber (MMF): Multi-mode fiber is commonly used for shorter-distance applications, such as local area networks (LANs) and data centers. The speeds achievable with multi-mode fiber depend on the generation of the fiber and the equipment used. Older generations of multi-mode fiber (OM1 and OM2) support data rates up to 10 Gbps. Newer generations (OM3, OM4, and OM5) can support data rates up to 100 Gbps or higher, depending on the transmission technology and equipment.

It's important to note that the actual speed achieved in a fiber optic network depends not only on the fiber optic cable but also on the network infrastructure, equipment, and protocols used. Additionally, the speed can vary based on the specific implementation and advancements in fiber optic technology.

Fiber optic cables are capable of providing significantly higher speeds compared to traditional copper cables, making them the preferred choice for high-speed data transmission and bandwidth-intensive applications.

What is the difference between fiber optic cable and copper cable?

There are several key differences between fiber optic cables and copper cables, which are commonly used for data transmission. Here are some of the main distinctions:

- Transmission Medium:

- Fiber Optic Cable: Fiber optic cables transmit data using light signals through optical fibers made of glass or plastic.

- Copper Cable: Copper cables transmit data using electrical signals through copper conductors.

- Bandwidth and Speed:

- Fiber Optic Cable: Fiber optic cables offer significantly higher bandwidth and faster data transmission speeds compared to copper cables. They have the potential to support much higher data rates, such as 10 Gbps, 40 Gbps, or even 100 Gbps and beyond.

- Copper Cable: Copper cables have lower bandwidth capacity and slower data transmission speeds. They are typically limited to data rates up to 10 Gbps in shorter distances.

- Transmission Distance:

- Fiber Optic Cable: Fiber optic cables can transmit data over long distances without significant signal degradation. Single-mode fiber can transmit signals for tens or even hundreds of kilometers.

- Copper Cable: Copper cables have limitations in transmission distance due to signal loss and degradation. They are suitable for shorter distances, typically within a few hundred meters.

- Immunity to Interference:

- Fiber Optic Cable: Fiber optic cables are immune to electromagnetic interference (EMI), as they use light signals for data transmission. They are not affected by electrical noise or nearby power lines.

- Copper Cable: Copper cables are susceptible to EMI and can be affected by electromagnetic fields, radio frequency interference, and crosstalk from neighboring cables.

- Security:

- Fiber Optic Cable: Fiber optic cables provide a higher level of security compared to copper cables. They do not radiate signals that can be easily intercepted, making them more difficult to tap into without detection.

- Copper Cable: Copper cables emit electromagnetic signals that can be intercepted and tapped into, posing potential security risks.

- Size and Weight:

- Fiber Optic Cable: Fiber optic cables are thinner and lighter compared to copper cables. They are more flexible and occupy less physical space, making them easier to install and manage.

- Copper Cable: Copper cables are thicker and heavier due to the metal conductors, making them less flexible and requiring more space for installation.

- Cost:

- Fiber Optic Cable: Fiber optic cables are generally more expensive than copper cables in terms of initial installation costs. However, their long-term benefits, such as higher performance, lower maintenance, and future-proofing, can justify the investment.

- Copper Cable: Copper cables are generally less expensive than fiber optic cables in terms of initial costs.

These differences make fiber optic cables the preferred choice for high-speed, long-distance, and secure data transmission, while copper cables are commonly used for shorter distances and lower bandwidth applications. The choice between fiber optic and copper cables depends on the specific requirements of the application, budget constraints, and other factors such as the existing infrastructure and compatibility with equipment.

Fig 4. Fiber vs cable

Fiber optic cable structure

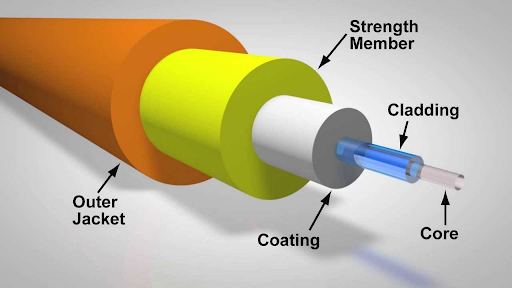

The structure of a fiber optic cable consists of several components designed to protect and transmit optical signals. Here are the main elements found in a typical fiber optic cable:

- Core: The core is the central part of the fiber optic cable through which light signals travel. It is a cylindrical region made of optically pure glass or plastic material. The core's diameter can vary, depending on the type of fiber (single-mode or multi-mode), but it is typically around 8 to 10 micrometers for single-mode fibers and 50 to 62.5 micrometers for multi-mode fibers.

- Cladding: Surrounding the core is the cladding, which is a layer of material with a lower refractive index than the core. It helps confine the light within the core through the principle of total internal reflection. The cladding's refractive index is carefully chosen to ensure that light is reflected into the core rather than being absorbed or escaping.

- Coating: The cladding is further protected by a coating, also known as a buffer. The coating is typically made of a polymer material, such as acrylate or silicone, and serves multiple purposes. It provides mechanical protection to the fiber, preventing it from bending or breaking easily. Additionally, the coating acts as an insulator, protecting the fiber from moisture, chemicals, and other external elements.

- Strength Members: To provide additional mechanical strength and support, fiber optic cables often have one or more strength members. These can be made of materials like aramid yarns (e.g., Kevlar) or fiberglass strands. The strength members help protect the delicate fibers from stretching or being damaged during installation and handling.

- Jacket: The outermost layer of the fiber optic cable is the jacket. It protects against environmental factors such as moisture, UV radiation, and abrasion. The jacket is typically made of durable material, such as PVC (polyvinyl chloride), LSZH (low smoke zero halogens), or PE (polyethylene). The color of the jacket may vary depending on the application and industry standards.

It's important to note that fiber optic cables can have various designs and configurations depending on their specific applications. For example, loose-tube cables are commonly used for outdoor installations, where the fibers are housed in individual buffer tubes surrounded by a central strength member. Tight-buffered cables, on the other hand, have a thicker coating directly on each fiber, making them more suitable for indoor use and short-distance applications.

Overall, the combination of core, cladding, coating, strength members, and jacket in a fiber optic cable ensures efficient transmission of light signals while protecting external factors and mechanical stresses.

Fig 5. Fiber optic structure

How does the Fiber optic cable work?

https://www.youtube.com/watch?v=jZOg39v73c4

Fiber optic cables work based on the principle of transmitting data through the use of light signals. Here's a simplified explanation of how fiber optic cables work:

- Light Generation: At one end of the fiber optic cable, a light source such as a laser diode or an LED generates a stream of light pulses. These light pulses carry data in the form of binary signals (0s and 1s).

- Signal Encoding: Before transmitting the data, it is converted into a format suitable for optical transmission. This encoding process typically involves converting electrical signals into optical signals using a modulator.

- Light Transmission: The generated light pulses are then injected into the core of the fiber optic cable. The core, which is made of optically pure glass or plastic, allows the light to travel through it due to the principle of total internal reflection.

- Total Internal Reflection: As the light travels through the core of the fiber optic cable, it encounters the cladding, which has a lower refractive index than the core. This causes the light to be reflected into the core at each interface, rather than escaping through the cladding. This phenomenon is known as total internal reflection and allows the light to propagate down the length of the fiber with minimal loss.

- Signal Reception: At the receiving end of the fiber optic cable, there is a light detector, such as a photodiode or a photodetector, that detects the light pulses. The detector converts the received light signals back into electrical signals.

- Signal Processing: The electrical signals are then processed and decoded to retrieve the original data. This may involve amplification, filtering, and other signal-processing techniques to ensure accurate data recovery.

- Data Transmission: The retrieved data can be further processed or sent to its intended destination, such as a computer, a networking device, or another communication system. This allows for the transmission of vast amounts of data over long distances at high speeds.

It's important to note that fiber optic cables can support the simultaneous transmission of multiple light signals by using techniques such as wavelength-division multiplexing (WDM). This allows for increased data capacity and efficient utilization of the fiber optic cable's bandwidth.

Overall, the use of light signals and the principle of total internal reflection enable fiber optic cables to provide high-speed, reliable, and secure data transmission over long distances, making them a crucial technology for telecommunications, networking, and various other industries.

Fiber optic cable types

There are several types of fiber optic cables available, each designed to meet specific requirements in terms of transmission distance, bandwidth, and environmental conditions. Here are the main types of fiber optic cables:

- Single-Mode Fiber (SMF): Single-mode fiber is designed to carry a single mode of light, allowing for long-distance transmission with low signal loss. It has a small core size (typically 8 to 10 micrometers) and uses a laser light source. SMF is commonly used for long-haul telecommunications, high-speed internet backbones, and applications that require transmission over extended distances.

- Multi-Mode Fiber (MMF): Multi-mode fiber is designed to carry multiple modes of light simultaneously. It has a larger core size (typically 50 to 62.5 micrometers) compared to single-mode fiber, allowing for easier coupling of light sources such as LEDs. MMF is suitable for short to medium-distance transmissions, such as local area networks (LANs), campus networks, and data center interconnections.a. OM1 (62.5/125 µm): This type of multi-mode fiber was the first widely used MMF. It has a core size of 62.5 micrometers and a cladding size of 125 micrometers. OM1 fiber supports data rates up to 1 Gbps for short distances.b. OM2 (50/125 µm): OM2 fiber has a core size of 50 micrometers and a cladding size of 125 micrometers. It provides higher bandwidth compared to OM1, supporting data rates up to 10 Gbps for short distances.c. OM3 (50/125 µm): OM3 fiber, also known as laser-optimized multi-mode fiber (LOMMF), has a core size of 50 micrometers and a cladding size of 125 micrometers. It supports higher bandwidth and longer transmission distances compared to OM1 and OM2. OM3 fiber is commonly used for 10 Gbps and 40 Gbps Ethernet applications.d. OM4 (50/125 µm): OM4 fiber is an enhanced version of OM3 fiber, offering even higher bandwidth and longer reach. It has the same core size of 50 micrometers and cladding size of 125 micrometers. OM4 fiber is used for high-speed data transmission in data centers and other demanding applications.

- Plastic Optical Fiber (POF): Plastic optical fiber is an alternative to glass fibers, commonly used for shorter-distance applications, consumer electronics, and automotive applications. POF has a larger core size (typically around 1 mm) and lower bandwidth compared to glass fibers. It is more flexible, easier to install, and less expensive than glass fibers.

- Specialty Fiber: In addition to single-mode and multi-mode fibers, there are specialty fibers designed for specific applications. These includea. Polarization-Maintaining Fiber (PMF): PMF is used in applications that require the preservation of light polarization, such as fiber optic gyroscopes and coherent optical communications.b. Dispersion-Shifted Fiber (DSF): DSF is designed to minimize the effects of chromatic dispersion, which can limit the transmission distance and bandwidth. It is used in long-haul and high-capacity transmission systems.c. Non-Zero Dispersion-Shifted Fiber (NZ-DSF): NZ-DSF is a type of fiber designed to shift the zero dispersion wavelength away from the operating window, providing improved transmission performance and allowing for higher data rates.

Fig 6. Submarine cables

-

Single-Mode Fiber (SMF):

- Working Principle: Single-mode fiber is designed to carry a single mode of light, allowing for long-distance transmission with low signal loss. It has a small core size, enabling the light to propagate in a straight line.

- Applications: SMF is commonly used in long-haul telecommunications, high-speed internet backbones, and applications that require transmission over extended distances.

- Usage: It is suitable for transmitting data over long distances, such as transcontinental communication links and intercity networks.

- Pros: Long transmission distances, low signal loss, high bandwidth capacity, suitable for high-speed and long-haul applications.

- Cons: More expensive than multi-mode fiber, requires precision alignment for coupling light sources.

Fig 7. Single-mode vs multi-mode

-

Multi-Mode Fiber (MMF):

- Working Principle: Multi-mode fiber is designed to carry multiple modes of light simultaneously. It has a larger core size, allowing for easier coupling of light sources.

- Applications: MMF is suitable for short to medium-distance transmission in local area networks (LANs), campus networks, and data center interconnections.

- Usage: It is used in shorter-range applications, including LAN connections, enterprise networks, and video distribution systems.

- Pros: Cost-effective, larger core size facilitates easier connections, is suitable for shorter distances, and supports lower-cost light sources such as LEDs.

- Cons: Limited transmission distance, higher modal dispersion, lower bandwidth compared to single-mode fiber.

-

OM1 (62.5/125 µm):

- Applications: OM1 fiber was the first widely used MMF. It supports data rates up to 1 Gbps for short distances.

- Usage: It is suitable for legacy LAN applications and short-range data transmission.

-

OM2 (50/125 µm):

- Applications: OM2 fiber provides higher bandwidth compared to OM1, supporting data rates up to 10 Gbps for short distances.

- Usage: It is commonly used in LANs, data centers, and premises networks.

-

OM3 (50/125 µm):

- Applications: OM3 fiber, also known as laser-optimized multi-mode fiber (LOMMF), supports higher bandwidth and longer transmission distances than OM1 and OM2. It is commonly used for 10 Gbps and 40 Gbps Ethernet applications.

- Usage: It is suitable for high-speed LANs, data centers, and backbone connections.

-

OM4 (50/125 µm):

- Applications: OM4 fiber is an enhanced version of OM3 fiber, offering even higher bandwidth and longer reach.

- Usage: It is used for high-speed data transmission in data centers, high-performance computing, and other demanding applications.

-

Plastic Optical Fiber (POF):

- Working Principle: POF uses a larger core made of plastic material to transmit light signals. It operates on the principle of total internal reflection.

- Applications: POF is commonly used in consumer electronics, automotive applications, and short-distance communication systems.

- Usage: It is suitable for home networking, automotive networking, and consumer electronics applications such as audio systems and gaming consoles.

- Pros: Flexibility, ease of installation, lower cost compared to glass fibers.

- Cons: Lower bandwidth, higher attenuation, and limited transmission distance compared to glass fibers.

-

Specialty Fiber:

-

Polarization-Maintaining Fiber (PMF):

- Working Principle: PMF is designed to maintain the polarization state of light signals throughout transmission.

- Applications: PMF is used in applications that require polarization preservation, such as fiber optic gyroscopes and coherent optical communications.

- Usage: It is suitable for precision sensing and communication systems.

- Pros: Maintains light polarization, and enables accurate sensing and communication.

- Cons: More expensive than standard fibers, limited applications requiring polarization control.

-

Dispersion-Shifted Fiber (DSF):

- Working Principle: DSF is designed to minimize the effects of chromatic dispersion, which can limit transmission distance and bandwidth.

- Applications: DSF is used in long-haul and high-capacity transmission systems.

- Usage: It is suitable for long-distance communication links and high-speed data transmission.

- Pros: Reduced chromatic dispersion, and longer transmission distances.

- Cons: Limited applications, the higher cost compared to standard fibers.

-

Non-Zero Dispersion-Shifted Fiber (NZ-DSF):

- Working Principle: NZ-DSF is a type of fiber designed to shift the zero dispersion wavelength away from the operating window.

- Applications: NZ-DSF provides improved transmission performance and higher data rates.

- Usage: It is suitable for high-speed long-haul transmission systems.

- Pros: Improved transmission performance, and higher data rates.

- Cons: Limited applications, the higher cost compared to standard fibers.

-

These descriptions provide an overview of the working principles, applications, usage, pros, and cons of each type of fiber optic cable. It's important to note that the specific choice of fiber optic cable depends on the requirements of the particular application and the desired performance characteristics.

Comparing table

Here's a comparison table summarizing the key characteristics of different types of fiber optic cables:

Table 2. Comparison Table

| Fiber Optic Cable Type | Single-Mode Fiber (SMF) | Multi-Mode Fiber (MMF) | Plastic Optical Fiber (POF) | Specialty Fiber |

| Core Size | Small (~8-10 µm) | Larger (50-62.5 µm) | Larger (1 mm) | Varies |

| Light Source | Laser | LED/Laser | LED/Laser | Varies |

| Transmission Distance | Long distance | Short to medium distance | Short distance | Varies |

| Bandwidth Capacity | High | Lower | Lower | Varies |

| Applications | Long-haul telecom, high-speed internet, extended distances | LANs, data centers, premises networks | Consumer electronics, automotive applications, short-distance communication | Specialized applications like fiber optic gyroscopes, coherent optical communications |

| Pros | Long transmission distances, low signal loss, high bandwidth capacity | Cost-effective, easier connections, suitable for shorter distances | Flexibility, ease of installation, lower cost | Application-specific advantages (e.g., polarization maintenance, dispersion control) |

| Cons | More expensive, precision alignment required | Limited transmission distance, higher modal dispersion | Lower bandwidth, higher attenuation | Higher cost, limited applications requiring specialty features |

Please note that this is a general comparison, and specific characteristics and performance may vary based on the specific manufacturer, grade, and specifications of the fiber optic cable. It's essential to consider the specific requirements and application needs when selecting a fiber optic cable.

Fig 8. Using fiber optic cables

Fiber optic cable application

Fiber optic cables have a wide range of applications across various industries. Here are some of the key areas where fiber optic cables are commonly used:

- Telecommunications: Fiber optic cables form the backbone of modern telecommunications networks. They are used for long-distance, high-speed data transmission in telephone networks, internet service providers (ISPs), and mobile networks. Fiber optics enable the efficient and reliable transfer of voice, data, and video signals over long distances, supporting global connectivity.

- Internet and Data Communication: Fiber optic cables play a vital role in enabling high-speed internet connections. They are used in data centers, server farms, and networking infrastructure to support the growing demand for bandwidth-intensive applications and services. Fiber optics enable fast and reliable data transmission, facilitating activities such as web browsing, video streaming, cloud computing, and online gaming.

- Cable Television (CATV): Fiber optic cables are used in cable television systems for transmitting video, audio, and data signals. They provide the capacity to deliver high-definition (HD) and ultra-high-definition (UHD) video content to homes and businesses. Fiber optics also support interactive services, video on demand (VOD), and other advanced features in cable TV networks.

- Medical Applications: Fiber optic cables have various applications in the medical field. They are used in endoscopy and minimally invasive surgeries, allowing doctors to visualize internal organs and perform precise procedures. Fiber optics also facilitate medical imaging techniques such as optical coherence tomography (OCT) and laser-based therapies.

- Industrial and Manufacturing: Fiber optic cables find applications in industrial environments where electrical noise, electromagnetic interference (EMI), and hazardous conditions are concerns. They are used for industrial automation, control systems, sensing, and monitoring. Fiber optics provide reliable communication and data transfer in harsh industrial environments, including oil and gas, manufacturing, and transportation sectors.

- Defense and Aerospace: Fiber optic cables are crucial in defense and aerospace applications. They are used in secure communication systems, radar systems, surveillance systems, avionics, and satellite communications. Fiber optics offer advantages such as high data security, immunity to EMI, lightweight design, and resistance to harsh environmental conditions.

- Sensing and Monitoring: Fiber optic cables are utilized for various sensing and monitoring applications. Fiber optic sensors can measure temperature, strain, pressure, vibrations, and other physical parameters. They are used in structural health monitoring of buildings, bridges, and pipelines, as well as in environmental monitoring and security systems.

- Research and Development: Fiber optic cables play a significant role in research and development laboratories. They are used in optical experiments, spectroscopy, fiber optic sensing research, and testing of new optical technologies. Fiber optics enable accurate and precise measurements, making them indispensable in scientific research.

These are just a few examples of the wide-ranging applications of fiber optic cables. The versatility, high bandwidth capacity, and reliability of fiber optics make them indispensable in modern communication, technology, and industrial sectors.

Fig 9. Fiber optic cables usage

Where is a Fiber optic cable used?

Fiber optic cables are used in a wide range of applications and industries. Here are some common locations and areas where fiber optic cables are deployed:

- Telecommunication Networks: Fiber optic cables are extensively used in telecommunication networks for long-distance transmission of voice, data, and video signals. They connect telephone exchanges, internet service providers (ISPs), mobile network towers, and data centers to provide high-speed, reliable communication services.

- Internet Backbone: Fiber optic cables form the backbone of the Internet, connecting different regions and continents. They enable the transmission of vast amounts of data between data centers, network nodes, and internet exchange points, facilitating global connectivity.

- Local Area Networks (LANs): Fiber optic cables are used in LAN environments, such as corporate offices, universities, and government institutions. They provide high-speed connectivity between network switches, routers, and end devices. Fiber optics are particularly beneficial in environments that require high bandwidth, low latency, and secure data transmission.

- Data Centers: Fiber optic cables are crucial components in data centers, where they interconnect servers, storage systems, and networking infrastructure. They enable fast and efficient data transfer between different components within the data center and support high-capacity computing and cloud services.

- Cable Television (CATV) Networks: Fiber optic cables are used in cable television systems to distribute video, audio, and data signals to subscribers. They allow for the transmission of high-definition (HD) and ultra-high-definition (UHD) television content, video on demand (VOD), and interactive services.

- Security and Surveillance Systems: Fiber optic cables are utilized in security and surveillance systems for transmitting video feeds and data from cameras and sensors. They provide high-quality video transmission over long distances and are resistant to electromagnetic interference, making them ideal for surveillance applications.

- Industrial and Manufacturing Environments: Fiber optic cables find applications in industrial settings for communication, control systems, and monitoring. They are used in industrial automation, process control, robotics, and machine vision systems. Fiber optics offer immunity to electrical noise, resistance to harsh environments, and enhanced safety in hazardous locations.

- Medical and Healthcare: Fiber optic cables play a critical role in medical applications such as endoscopy, surgical procedures, medical imaging, and diagnostics. They enable high-resolution imaging, precise light delivery, and real-time data transmission in medical equipment and systems.

- Aerospace and Defense: Fiber optic cables are utilized in aerospace and defense applications, including aircraft avionics, secure communication systems, radar systems, and satellite communications. They provide lightweight, high-speed, and secure data transmission in demanding and high-risk environments.

- Research and Development: Fiber optic cables are used in research laboratories and academic institutions for experiments, testing, and data transmission in various scientific fields, including physics, chemistry, biology, and engineering.

These are just a few examples of the many locations and areas where fiber optic cables are used. The versatility, high bandwidth capacity, and reliable performance of fiber optics make them essential in modern communications, technology, and industrial sectors.

Fig 10. Tactical Fiber Optic Cable

How can use the Fiber optic cable?

Fiber optic cables are used to establish high-speed, reliable, and secure communication links for various applications. Here are the general steps to use fiber optic cables:

- Planning and Design:

- Determine the communication requirements: Assess the bandwidth, transmission distance, and specific needs of the application.

- Select the appropriate fiber optic cable type: Choose the suitable fiber type (single-mode or multi-mode) based on the required transmission distance and bandwidth capacity.

- Consider installation environment: Evaluate factors such as indoor or outdoor installation, temperature range, and protection requirements.

- Cable Installation:

- Prepare the installation route: Identify the path for the fiber optic cable, considering any obstacles or existing infrastructure.

- Prepare cable termination points: Install connectors or splices at the cable termination points, such as patch panels, connectors, or fusion splices.

- Install the fiber optic cable: Carefully place and secure the cable along the planned route, following installation guidelines and best practices.

- Test the cable: Perform cable testing using appropriate equipment to verify the cable's integrity and ensure proper installation.

- Cable Connection:

- Connectorization: Terminate the fiber optic cable ends with connectors using appropriate tools and techniques. This involves stripping the cable, cleaning the fibers, and attaching connectors.

- Fusion Splicing: If fusion splicing is required, carefully align and fuse the fiber ends together using fusion splicing equipment.

- Testing and Verification: After cable connection, perform tests such as optical loss testing or OTDR (Optical Time-Domain Reflectometer) testing to ensure proper connectivity and performance.

- Equipment Connection:

- Connect to active equipment: Connect the fiber optic cable to the respective active equipment, such as switches, routers, servers, or transceivers.

- Verify connections: Ensure proper alignment and secure connections between the fiber optic cable connectors and the equipment.

- Network Operation and Maintenance:

- Monitor and troubleshoot: Regularly monitor the fiber optic network for performance, signal quality, and potential issues. Use appropriate testing and monitoring tools to identify and resolve any problems.

- Perform maintenance activities: Clean connectors periodically, inspect cables for damage, and perform preventive maintenance to ensure optimal performance.

- Expand or upgrade the network: If needed, additional fiber optic cables can be installed and connected to expand the network or accommodate higher bandwidth requirements.

It's worth noting that fiber optic cable installation and maintenance may require specialized knowledge and skills. It is recommended to consult with professionals or experts in fiber optic network installation to ensure proper installation and optimal performance.

Fig 11. Fiber optic cable types

Pros and Cons of Using Fiber Optic Cables

Using fiber optic cables offer several advantages and disadvantages. Here are the pros and cons of using fiber optic cables:

Pros:

- High Bandwidth: Fiber optic cables can transmit a vast amount of data with high bandwidth capacity, making them suitable for applications that require fast and efficient data transfer.

- Long Transmission Distance: Fiber optic cables can transmit data over long distances without significant signal degradation, allowing for communication links spanning several kilometers or even transcontinental distances.

- Immunity to Electromagnetic Interference (EMI): Unlike copper cables, fiber optic cables are immune to EMI, which can degrade signal quality. This makes fiber optic cables more reliable and suitable for environments with high levels of electrical noise.

- Security: Fiber optic cables offer a higher level of security because they do not emit electromagnetic signals that can be easily tapped or intercepted. They are more difficult to tap without detection, making them ideal for secure communication networks.

- Lightweight and Compact: Fiber optic cables are lightweight and have a smaller diameter compared to copper cables, allowing for easier installation and efficient use of space in cable ducts or trays.

- Lower Signal Loss: Fiber optic cables experience significantly lower signal loss compared to copper cables, enabling longer transmission distances and higher-quality data transmission.

- Resistance to Environmental Factors: Fiber optic cables are less affected by environmental factors such as temperature fluctuations, moisture, and corrosive substances. They are suitable for deployment in harsh environments.

Cons:

- Cost: Fiber optic cables can be more expensive to install and maintain compared to traditional copper cables. The specialized equipment and expertise required for installation contribute to the higher initial investment cost.

- Fragility: Fiber optic cables are delicate and can be damaged if not handled with care during installation or maintenance. They may require additional protection, such as proper ducting or conduit, to prevent accidental damage.

- Limited Bend Radius: Fiber optic cables have a minimum bend radius that should not be exceeded to avoid signal loss or cable damage. Care must be taken during installation to ensure proper bending practices.

- Limited Availability of Skill Set: Fiber optic cable installation and maintenance require specialized knowledge and skills. Trained professionals are needed for proper installation, splicing, and testing, which may limit the availability of expertise in some areas.

- Compatibility: Fiber optic cables may require different connectors and equipment compared to traditional copper cables, which may add complexity to network infrastructure upgrades or compatibility issues with existing equipment.

Despite these cons, the advantages of fiber optic cables, such as high bandwidth, long-distance transmission, immunity to EMI, and enhanced security, make them the preferred choice for many applications requiring fast and reliable data communication.

Top brands which manufactured Fiber optic cable

Several top brands manufacture fiber optic cables. Here are some well-known brands in the fiber optic cable industry:

- Corning Incorporated: Corning is a leading manufacturer of fiber optic cables and other optical communication solutions. They offer a wide range of fiber optic cables for various applications, including single-mode, multi-mode, and specialty fibers.

- Prysmian Group: Prysmian Group is a global leader in the production of fiber optic cables. They offer a comprehensive portfolio of fiber optic cables for different industries and applications, including telecommunications, energy, and data centers.

- CommScope: CommScope is a prominent provider of fiber optic cables and connectivity solutions. They offer a diverse range of fiber optic cables designed for high-performance networks, including indoor, outdoor, and specialty cables.

- AFL Telecommunications: AFL Telecommunications is a leading manufacturer of fiber optic cables and accessories. They offer a wide range of fiber optic cable solutions, including loose-tube, tight-buffered, and ribbon cables, catering to various industries and applications.

- Belden Inc.: Belden is a well-known manufacturer of networking and connectivity solutions, including fiber optic cables. They offer a range of fiber optic cables designed for high-speed data transmission, industrial applications, and enterprise networks.

- OFS (Furukawa Electric Co., Ltd.): OFS is a global leader in optical fiber and cable solutions. They provide a comprehensive range of fiber optic cables for various applications, including telecommunications, data centers, and specialty markets.

- Nexans: Nexans is a leading cable manufacturer that offers a wide range of fiber optic cables for different industries and applications. Their fiber optic cables are designed for high-performance data transmission, connectivity, and network infrastructure.

- Sumitomo Electric Industries, Ltd.: Sumitomo Electric is a renowned manufacturer of fiber optic cables and components. They provide a broad portfolio of fiber optic cables, including standard and specialty cables, for telecommunications, automotive, and industrial applications.

These are just a few examples of top brands in the fiber optic cable industry. It's important to note that the choice of the brand may depend on specific requirements, budget, and regional availability. It's recommended to research and consult with industry experts or suppliers to select the most suitable brand and product for your specific application.

How can choose the proper Fiber optic cable?

Choosing the proper fiber optic cable requires careful consideration of various factors. Here are some key points to help you select the appropriate fiber optic cable for your specific application:

- Determine the Application Requirements:

- Transmission Distance: Consider the distance over which the cable needs to transmit data. Single-mode fiber is suitable for long-distance transmission, while multi-mode fiber is suitable for shorter distances.

- Bandwidth Requirements: Assess the required bandwidth capacity to ensure the fiber optic cable can support the data rates of your application.

- Environmental Factors: Consider the installation environment, such as indoor or outdoor, temperature range, moisture, and exposure to chemicals or abrasion. Choose cables with appropriate jackets and protective features accordingly.

- Fiber Type:

- Single-Mode (SMF) or Multi-Mode (MMF): Determine whether your application requires single-mode or multi-mode fiber. Single-mode fiber provides long-distance transmission but requires more precise alignment and higher-cost components. Multi-mode fiber is suitable for shorter distances and is more cost-effective.

- Cable Construction:

- Cable Size: Consider the diameter and flexibility of the fiber optic cable, depending on installation requirements and space limitations.

- Cable Jacket: Select a jacket material that is suitable for the environmental conditions of the installation site, such as PVC, LSZH (Low Smoke Zero Halogen), or an armored jacket for added protection.

- Cable Strength Members: Evaluate if the cable requires additional strength members, such as aramid yarn or steel armor, for enhanced durability and tensile strength.

- Compatibility:

- Connectors: Ensure compatibility between the fiber optic cable and the connectors used in your network equipment. Common connector types include LC, SC, ST, and MPO/MTP.

- Network Equipment: Consider the compatibility of the fiber optic cable with the active equipment, such as switches, routers, or transceivers, that you will be using in your network.

- Quality and Reliability:

- Choose reputable and reliable manufacturers or brands known for their quality and adherence to industry standards.

- Look for cables that have been tested and certified to meet or exceed industry standards for performance, such as ISO/IEC, TIA/EIA, or Telcordia.

- Consultation and Expertise:

- Seek advice from experienced professionals or consultants who specialize in fiber optic networks. They can provide valuable guidance based on their expertise and knowledge of specific applications.

By considering these factors and consulting with experts, you can choose the proper fiber optic cable that meets your application requirements, ensures reliable performance, and offers long-term durability.

Fig 12. Different types of fiber optic cable

Conclusion

In conclusion, fiber optic cables are a crucial component of modern communication networks, offering high-speed, reliable, and secure data transmission. They have revolutionized the way we connect and communicate, providing numerous advantages over traditional copper cables.

The pros of using fiber optic cables include high bandwidth capacity, long transmission distances, immunity to electromagnetic interference (EMI), enhanced security, lightweight and compact design, lower signal loss, and resistance to environmental factors. These benefits make fiber optic cables ideal for a wide range of applications, from telecommunications and data centers to industrial and automotive sectors.

However, there are also some considerations to keep in mind. The cons of fiber optic cables include higher initial cost, fragility requiring careful handling, limited bend radius, the need for specialized knowledge and skills, and potential compatibility issues with existing equipment.

To choose the proper fiber optic cable, it is essential to assess the application requirements, including transmission distance, bandwidth, and environmental factors. Selecting the appropriate fiber type (single-mode or multi-mode), cable construction, and considering compatibility with connectors and network equipment are key factors in making the right choice. Consulting with experts in fiber optic networks and reputable manufacturers can provide valuable guidance in selecting a high-quality and reliable fiber optic cable.

Overall, fiber optic cables have revolutionized the way we transmit and receive data, enabling faster and more efficient communication. Their numerous advantages make them a preferred choice for various industries and applications, facilitating the advancement of technology and connectivity in today's interconnected world.

To recap

Here are 15 frequently asked questions about fiber optic cables along with their answers:

- What is a fiber optic cable?

A fiber optic cable is a type of cable composed of thin strands of glass or plastic fibers that transmit data using light signals.

- How does a fiber optic cable transmit data?

Fiber optic cables transmit data through the principle of total internal reflection, where light signals bounce off the walls of the fiber and travel through the core, carrying data.

- What are the advantages of fiber optic cables over copper cables?

Fiber optic cables offer higher bandwidth, longer transmission distances, immunity to electromagnetic interference (EMI), enhanced security, and lower signal loss compared to copper cables.

- What are the different types of fiber optic cables?

The main types of fiber optic cables are single-mode fiber (SMF), multi-mode fiber (MMF), plastic optical fiber (POF), and specialty fibers designed for specific applications.

- What are the applications of fiber optic cables?

Fiber optic cables are used in various applications, including telecommunications, data centers, internet connectivity, cable television, medical imaging, industrial automation, and military/aerospace systems.

- What is the maximum transmission distance of fiber optic cables?

Single-mode fiber optic cables can transmit data over long distances, typically ranging from tens of kilometers to hundreds of kilometers, depending on the specific cable and equipment used.

- Can fiber optic cables be used for both voice and data transmission?

Yes, fiber optic cables can transmit both voice and data signals simultaneously, making them suitable for integrated voice, video, and data communication systems.

- Are fiber optic cables immune to lightning strikes?

While fiber optic cables are not completely immune to lightning strikes, they are not as susceptible to damage or interference from electrical surges as copper cables.

- How is a fiber optic cable terminated or connected?

Fiber optic cables are terminated using connectors, such as LC, SC, or ST connectors, which are attached to the ends of the fibers. These connectors allow the cables to be connected to various devices or spliced together.

- Can fiber optic cables be spliced or repaired?

Yes, fiber optic cables can be spliced together using fusion splicing or mechanical splicing techniques. In case of damage, individual fibers can be repaired or replaced within the cable.

- Do fiber optic cables require special handling or maintenance?

Fiber optic cables require careful handling to avoid damage to the delicate fibers. Periodic inspection, cleaning of connectors, and adherence to proper bending radius guidelines are essential for maintenance.

- Are fiber optic cables secure from hacking or interception?

Fiber optic cables offer a high level of security since they do not emit electromagnetic signals that can be easily intercepted. Tapping into fiber optic cables without detection is difficult, making them more secure than copper cables.

- Can fiber optic cables be used for high-speed internet?

Yes, fiber optic cables are commonly used for high-speed internet connections, as they provide the necessary bandwidth and transmission capabilities to support fast data transfer.

- Are fiber optic cables more expensive than copper cables?

Fiber optic cables are generally more expensive than copper cables in terms of initial installation costs. However, their long-term benefits, such as higher performance, reliability, and lower maintenance costs, often justify the investment.

- Can fiber optic cables be used in harsh environments?

Yes, fiber optic cables are available with specialized jackets and protective layers to withstand harsh environmental conditions, including extreme temperatures, moisture, and chemical exposure.

Please note that these answers provide a general understanding of fiber optic cables. Specific details and considerations may vary depending on the manufacturer, grade, and application requirements of the fiber optic cable.

References

https://www.nestorcables.com/products/fibre-optic-cables.html

https://www.matrix-ndi.com/en/technology-blog/fiber-optic-cable-101-0

https://spectrum.ieee.org/legacy-fiber-optic-cables-speed-data-rates#toggle-gdpr

https://community.fs.com/blog/understanding-fiber-optic-cable-jacket-fire-rating.html

https://www.actcorp.in/blog/what-is-the-difference-between-fiber-optic-and-cable-internet

https://breanetworks.com/fiber-optic-cable/

https://www.nai-group.com/optical-fiber-technology-how-it-works/

https://www.fibreoptic.com.au/wp-content/uploads/2021/02/single-mode-vs-multimode-FIBERS.jpg

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecti …16th Apr 2025