Zero to Hero: The Unsung Power of Static Pressure in Engineering

Imagine a world where objects could effortlessly glide through the air with grace and precision, where buildings harnessed the invisible forces of fluids to optimize their designs, and where aircraft could conquer the skies with remarkable efficiency. All of this is made possible, in part, by a fascinating concept known as static pressure. As we delve into the realm of fluid mechanics and aerodynamics, let us unravel the secrets of this silent yet omnipresent force that shapes our engineering marvels and influences the very essence of how we interact with the world around us. From aircraft soaring through the heavens to the intricate workings of HVAC systems, static pressure is the unsung hero that silently propels progress forward. Join me on this exhilarating journey as we unlock the mysteries of static pressure and discover its remarkable impact on our daily lives!

What is static pressure?

Static pressure is the pressure exerted by a fluid (liquid or gas) that remains at rest. In other words, it is the pressure acting in all directions within a fluid without any motion. When a fluid is not moving, its molecules still have kinetic energy due to their random thermal motion, which results in the exertion of pressure on the container walls and any other surfaces in contact with the fluid.

In the context of airflow systems, such as in HVAC (Heating, Ventilation, and Air Conditioning) or ventilation systems, static pressure is the pressure exerted by air on the walls of the ducts, filters, and other components when the air is not flowing or is moving at a constant velocity. It is an essential parameter to consider in designing and analyzing such systems, as it affects the efficiency of air distribution and the overall performance of the system.

Static pressure is typically measured in units such as pascals (Pa), pounds per square inch (psi), inches of water column (inH2O), millimeters of water column (mmH2O), or inches of mercury (inHg), depending on the specific application and region. Understanding and controlling static pressure is crucial for ensuring optimal performance and energy efficiency in various fluid flow systems.

Find the perfect Pressure Sensor for your specific needs with our easy-to-navigate selection.

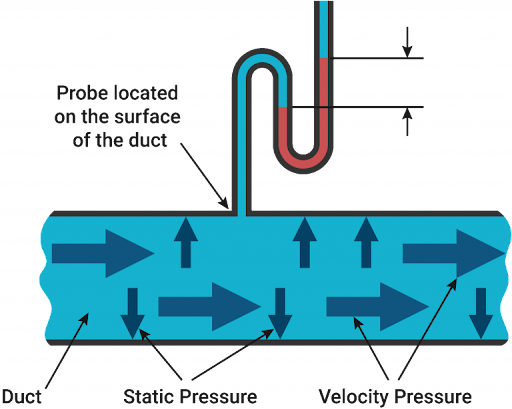

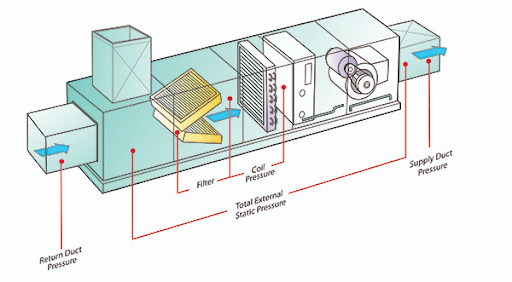

Fig 1. Static pressure

How is static pressure measured?

Static pressure is measured using devices called pressure gauges or pressure transducers. The measurement method may vary depending on the specific application and the type of fluid involved (gas or liquid). Here are some common methods for measuring static pressure: A manometer is a simple device used to measure fluid pressure. It consists of a U-shaped tube partially filled with a liquid, such as mercury or water. One end of the tube is connected to the fluid whose pressure needs to be measured, and the other end is open to the atmosphere. The pressure difference between the fluid and the atmosphere causes the liquid level in the two arms of the U-tube to shift, providing a visual indication of the static pressure.

- Digital Manometer: A digital manometer is a more advanced version of the traditional manometer, providing precise and digital readings of static pressure. It typically uses a pressure sensor and a display to show the pressure readings.

- Pressure Gauge: A pressure gauge is a mechanical device that directly measures the pressure of a fluid. It consists of a bourdon tube or diaphragm that deforms under the pressure of the fluid, which is then converted into a reading on a calibrated scale.

- Pressure Transducer: A pressure transducer is an electronic device that converts the fluid pressure into an electrical signal, which can be displayed on a digital readout or transmitted to a control system for further processing.

- Pitot Tube: In aerodynamics and airflow measurements, a pitot tube is used to measure the impact of stagnation pressure, which is the sum of the static pressure and dynamic pressure. By subtracting the dynamic pressure (measured using a separate tube) from the impact pressure, the static pressure can be determined.

- Pressure Taps: In more complex fluid flow systems, pressure taps may be installed at various points along the ductwork or pipelines to measure the static pressure at specific locations. These pressure taps are connected to pressure transducers or gauges for reading and analysis.

It's important to ensure that the pressure measurement device used is appropriate for the fluid being measured and the range of pressures involved. Regular calibration and maintenance of pressure measurement equipment are also necessary to ensure accurate and reliable readings.

What are the units of static pressure?

Static pressure can be measured using various units, and the choice of the unit depends on the specific application and the region where the measurement is being taken. Here are some common units of static pressure:

- Pascals (Pa): The SI unit of pressure is the pascal, which is equal to one newton per square meter (N/m²).

- Pounds per square inch (psi): A common imperial unit of pressure used in the United States and some other countries. One psi is approximately equal to 6894.76 pascals.

- Inches of water column (inH2O): This unit is often used to measure low-pressure differentials, such as in HVAC systems. One inch of water column is approximately equal to 249 pascals.

- Millimeters of water column (mmH2O): Similar to inches of water column, but measured in millimeters. One millimeter of water column is approximately equal to 9.81 pascals.

- Inches of mercury (inHg): This unit is commonly used in barometric pressure measurements and is equal to the pressure exerted by a column of mercury one inch high. One inch of mercury is approximately equal to 3386.39 pascals.

- Atmospheres (atm): The atmospheric pressure at sea level is approximately 1 atm, which is equivalent to 101,325 pascals.

- Bars (bar): One bar is equal to 100,000 pascals (or 0.1 megapascals).

- Torr: A unit commonly used in vacuum measurements, with one torr equivalent to 133.322 pascals.

When working with different units of static pressure, it's essential to ensure that the correct conversion factors are used to avoid errors in measurements and calculations. The choice of the unit may also depend on the conventions used in a particular industry or region.

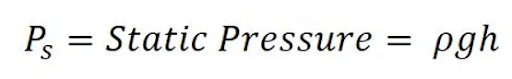

Static pressure formulas

Static pressure in fluid mechanics can be calculated using different formulas depending on the context and specific application. Here are some common formulas for calculating static pressure:

- For gas in a closed container: The static pressure of a gas in a closed container is given by the ideal gas law:

P = n * R * T / V

Where: P is the static pressure of the gas n is the number of moles of gas R is the ideal gas constant T is the temperature of the gas in kelvin V is the volume of the gas

- For a liquid at rest: The static pressure in a liquid at rest is calculated based on the height of the fluid column and the density of the liquid.

P = ρ * g * h

Where: P is the static pressure ρ is the density of the liquid g is the acceleration due to gravity h is the height of the fluid column

- For a fluid flowing in a pipe: The static pressure in a fluid flowing through a pipe can be determined using Bernoulli's equation, which relates pressure, velocity, and elevation along a streamline.

P + (ρ * V^2) / 2 + ρ * g * h = constant

Where: P is the static pressure of the fluid at a specific point along the streamline ρ is the fluid density V is the fluid velocity at that point g is the acceleration due to gravity h is the elevation of the point above a reference plane

- For pressure changes in ducts (HVAC systems): In HVAC systems, the static pressure drop in ducts can be calculated using pressure loss equations like the Darcy-Weisbach equation or the fan laws.

ΔP = (f * (L / D) * (V^2)) / (2 * D)

Where: ΔP is the static pressure drop f is the Darcy friction factor L is the length of the duct D is the hydraulic diameter of the duct V is the fluid velocity in the duct.

These are just a few examples of static pressure formulas. The appropriate formula used depends on the specific situation and the variables known or measured in the given fluid flow system.

Examples of using these formulas

Let's go through some examples of using the static pressure formulas in different scenarios:

Example 1: Gas in a Closed Container Suppose you have a closed container with 2 moles of nitrogen gas (N2) at a temperature of 300 Kelvin and a volume of 0.1 cubic meters. Using the ideal gas law formula, calculate the static pressure of the gas.

Given: n = 2 moles R = 8.314 J/(mol K) (ideal gas constant) T = 300 K V = 0.1 m³

Using the ideal gas law formula:

P = n * R * T / V P = 2 * 8.314 * 300 / 0.1 P ≈ 4988.4 pascals

Example 2: Static Pressure in a Liquid at Rest Consider a water tank with a height of 5 meters. Calculate the static pressure at the bottom of the tank due to the weight of the water.

Given: ρ = 1000 kg/m³ (density of water) g = 9.81 m/s² (acceleration due to gravity) h = 5 meters (height of the fluid column)

Using the formula for static pressure in a liquid at rest:

P = ρ * g * h P = 1000 * 9.81 * 5 P ≈ 49,050 pascals

Example 3: Static Pressure in a Fluid Flowing in a Pipe Suppose you have a water pipe with a fluid velocity of 2 m/s and an elevation of 10 meters above a reference plane. Calculate the static pressure in the pipe.

Given: ρ = 1000 kg/m³ (density of water) V = 2 m/s (fluid velocity) g = 9.81 m/s² (acceleration due to gravity) h = 10 meters (elevation above the reference plane)

Using Bernoulli's equation: P + (ρ * V^2) / 2 + ρ * g * h = constant

At two different points in the pipe, let's assume P1 and P2 represent the static pressures:

At point 1 (upstream): P1 + (1000 * 2^2) / 2 + 1000 * 9.81 * 10 = constant

At point 2 (downstream): P2 + (1000 * 2^2) / 2 + 1000 * 9.81 * 0 = constant

Since the pipe is horizontal (same elevation at both points), the elevation term cancels out, and we can equate the constant values:

P1 + (1000 * 2^2) / 2 = P2 + (1000 * 2^2) / 2

P1 = P2

This means that the static pressure at both points is the same.

Example 4: Static Pressure Drop in Ducts (HVAC Systems) Consider an HVAC duct with a length of 5 meters and a hydraulic diameter of 0.3 meters. The fluid velocity in the duct is 4 m/s. Calculate the static pressure drop using the Darcy-Weisbach equation with a friction factor of 0.02.

Given: L = 5 meters (duct length) D = 0.3 meters (hydraulic diameter) V = 4 m/s (fluid velocity) f = 0.02 (Darcy friction factor)

Using the Darcy-Weisbach equation:

ΔP = (f * (L / D) * (V^2)) / (2 * D) ΔP = (0.02 * (5 / 0.3) * (4^2)) / (2 * 0.3) ΔP ≈ 1.778 pascals

In this example, the static pressure drop in the HVAC duct is approximately 1.778 pascals.

Formulas table

Here's a table summarizing the formulas for calculating static pressure in different scenarios:

| Scenario | Formula |

| Gas in a Closed Container | P = n * R * T / V |

| Static Pressure in a Liquid at Rest | P = ρ * g * h |

| Static Pressure in a Fluid Flowing in a Pipe | P + (ρ * V^2) / 2 + ρ * g * h = constant |

| Static Pressure Drop in Ducts (HVAC Systems) | ΔP = (f * (L / D) * (V^2)) / (2 * D) |

In these formulas:

- P represents the static pressure (in Pascals, Pa).

- n is the number of moles of gas.

- R is the ideal gas constant (approximately 8.314 J/(mol K)).

- T is the temperature of the gas in Kelvin (K).

- V is the volume of the gas (in cubic meters, m³).

- ρ represents the density of the liquid or fluid (in kg/m³).

- g is the acceleration due to gravity (approximately 9.81 m/s²).

- h is the height of the fluid column (in meters, m).

- L is the length of the duct or pipe (in meters, m).

- D is the hydraulic diameter of the duct (in meters, m).

- f is the Darcy friction factor (dimensionless).

- ΔP represents the static pressure drop (in Pascals, Pa).

These formulas are essential tools for engineers and scientists working with fluid mechanics, aerodynamics, HVAC systems, and other applications involving fluid flow and pressure analysis.

Fig 2. Measuring static pressure

What causes static pressure in a fluid?

Static pressure in a fluid is caused by the random thermal motion of molecules within the fluid. When a fluid is at rest or in equilibrium, its molecules are in constant motion due to their kinetic energy. As they move, they collide with each other and with the walls of the container or surface they are in contact with.

These molecular collisions exert a force on the container walls or any surface within the fluid, creating pressure in all directions. Since the fluid is at rest, the net force on any given volume of the fluid is zero. However, at a microscopic level, individual molecular collisions contribute to the static pressure of the fluid.

In gases, such as air, the molecules are relatively far apart, and they move more freely, leading to lower density and lower static pressure compared to liquids. In liquids, the molecules are closer together and have less freedom to move, resulting in higher density and higher static pressure.

The static pressure is isotropic, meaning it acts equally in all directions within the fluid. In an enclosed fluid, like a closed container, the static pressure will be evenly distributed throughout the entire volume of the fluid.

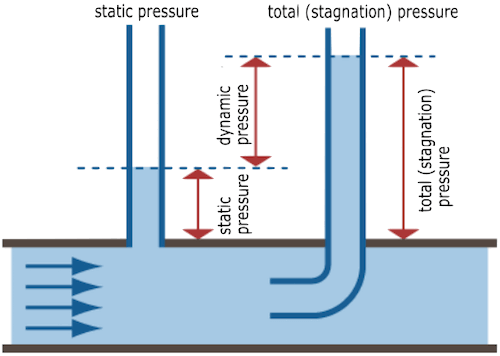

When an external force is applied to the fluid, such as air blowing over the surface or fluid flowing through a pipe, the fluid's motion adds dynamic pressure to the existing static pressure. The sum of the static pressure and dynamic pressure is known as the total pressure or stagnation pressure, and it remains constant in an incompressible fluid according to Bernoulli's principle.

In summary, static pressure in a fluid is a result of the molecular collisions and the thermal motion of the fluid's molecules when the fluid is at rest or in equilibrium. This pressure acts equally in all directions and is an essential concept in fluid mechanics and engineering applications, including HVAC systems, aerodynamics, and hydraulic systems.

What is the significance of static pressure in the industry?

Static pressure holds significant importance in various industries and engineering applications. Some of the key areas where static pressure plays a crucial role are

- HVAC Systems: In Heating, Ventilation, and Air Conditioning (HVAC) systems, static pressure is vital for ensuring efficient airflow and distribution of conditioned air throughout buildings. Properly designed and maintained static pressure ensures balanced airflows, prevents hot and cold spots, and helps HVAC equipment operate efficiently.

- Aerospace and Aviation: In the aerospace industry, static pressure is critical for aircraft design and performance analysis. It influences lift and drag forces on aircraft wings and airfoils, affecting flight characteristics and fuel efficiency.

- Industrial Ventilation: Static pressure is important for industrial ventilation systems to remove contaminants, maintain air quality, and provide proper ventilation in enclosed spaces, such as factories, warehouses, and cleanrooms.

- Fluid Flow Systems: In fluid dynamics and engineering, static pressure is considered in the design and analysis of pipelines, hydraulic systems, and water supply networks to ensure efficient fluid transportation and pressure regulation.

- Building Design and Energy Efficiency: Static pressure affects the overall energy efficiency of buildings. Properly balanced static pressure in ductwork and ventilation systems helps reduce energy consumption and operating costs.

- Environmental Monitoring: Static pressure is relevant in environmental monitoring and weather forecasting to understand atmospheric pressure variations, which influence weather patterns and climate conditions.

- Medical Devices: In medical devices like ventilators and respiratory equipment, static pressure regulation is crucial to maintain precise airflow rates and pressure levels for patient care.

- Plumbing Systems: In plumbing applications, static pressure is essential to ensure adequate water flow and pressure at fixtures and prevent potential damage to plumbing components.

- Filtration and Air Purification: Static pressure is considered in air filtration and purification systems to evaluate filter performance and pressure drop across filters, ensuring optimal airflow and filter efficiency.

- Research and Laboratory Equipment: In research, laboratories, and testing facilities, static pressure measurements are relevant for studying fluid behavior, pressure differentials, and controlled environments.

Overall, understanding and controlling static pressure is fundamental to the design, operation, and maintenance of various industrial processes and systems. Proper consideration of static pressure contributes to improved efficiency, safety, and performance across a wide range of industries and applications.

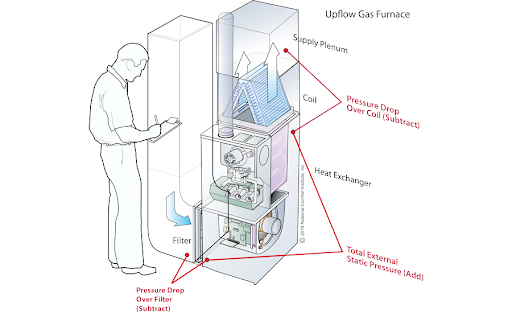

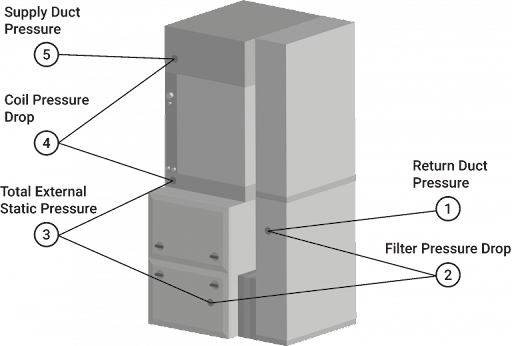

Fig 3. Static pressure using

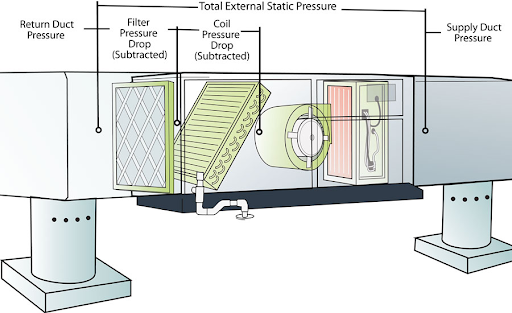

What does "static pressure drop" mean?

Static pressure drop, also known as static pressure loss or pressure drop, refers to the decrease in static pressure that occurs as a fluid (liquid or gas) flows through a duct, pipe, or any other flow passage. It is the difference in static pressure between two points along the flow path.

When a fluid moves through a flow passage, it encounters frictional resistance from the walls of the passage, as well as obstructions, bends, and changes in the cross-sectional area. These factors create frictional losses, which convert some of the fluid's energy into heat, resulting in a reduction in static pressure along the flow direction.

Static pressure drop is a crucial consideration in the design and analysis of fluid flow systems, as it directly affects the efficiency and performance of the system. High static pressure drop can lead to reduced flow rates, increased energy consumption, and decreased overall system efficiency.

In applications like HVAC systems, ducts, and pipelines, engineers and designers strive to minimize static pressure drop by selecting appropriate duct sizes, minimizing bends and obstructions, and ensuring smooth flow paths. This optimization helps to maintain proper airflow rates, energy efficiency, and effective operation of the system.

Measuring static pressure drop provides valuable information about the condition and performance of fluid flow systems. It allows engineers to identify potential issues, such as clogged filters, undersized ducts, or excessive friction, and make necessary adjustments to ensure optimal system operation.

In summary, static pressure drop refers to the reduction in static pressure that occurs as a fluid flows through a conduit or system due to frictional losses and other flow resistance factors. Understanding and managing static pressure drop is critical in various industries, including HVAC, fluid transportation, and process engineering, to ensure efficient and reliable fluid flow.

What causes a static pressure drop in ducts?

Static pressure drop in ducts is primarily caused by various factors that introduce resistance to the airflow as it moves through the ductwork. These factors contribute to frictional losses, which convert some of the fluid's kinetic energy into heat, resulting in a decrease in static pressure along the flow direction. Some of the key causes of static pressure drops in ducts include

- Frictional Resistance: As the air flows along the duct walls, it experiences friction between the air molecules and the duct surface. This friction creates resistance to the airflow, leading to a loss in static pressure.

- Duct Length: Longer duct runs result in higher static pressure drop due to the increased surface area in contact with the airflow, leading to greater frictional losses.

- Duct Size and Shape: Smaller and more restrictive duct sizes or irregularly shaped ducts cause greater frictional resistance and result in higher static pressure drop.

- Duct Obstructions: Objects within the duct, such as bends, elbows, dampers, and grilles, disrupt the smooth flow of air, leading to additional pressure losses.

- Filters and Air Grilles: Air filters and grilles in the duct system introduce resistance to the airflow, causing static pressure drop as air passes through them.

- Duct Roughness: The roughness of the inner surface of the duct can contribute to frictional resistance and increase static pressure drop.

- Changes in Duct Cross-Sectional Area: Sudden changes in the duct's cross-sectional area, such as contractions or expansions, create turbulence and result in pressure losses.

- Airflow Velocity: Higher airflow velocities lead to increased frictional losses and static pressure drop.

- Leaks and Inadequate Sealing: Air leaks and inadequate sealing in the ductwork allow air to escape, reducing the effective pressure and causing a static pressure drop.

- Multiple Branches and Junctions: Branches, junctions, and bifurcations in the duct system can lead to increased pressure losses due to redirection and mixing of the airflow.

To minimize static pressure drop in ducts, engineers and designers use techniques such as selecting appropriately sized ducts, optimizing the layout to reduce bends and obstructions, using smooth duct materials, ensuring proper sealing, and strategically placing dampers and grilles to balance the airflow distribution. Properly managing static pressure drop is crucial for ensuring efficient HVAC performance, maintaining desired airflow rates, and reducing energy consumption in ventilation and air conditioning systems.

Fig 5. static pressure drop in ducts

What is the relation between static pressure and velocity pressure?

The relationship between static pressure and velocity pressure is an essential concept in fluid dynamics, particularly in the context of fluid flow. Together, static pressure and velocity pressure make up the total pressure of a fluid.

- Static Pressure (P): Static pressure is the pressure exerted by a fluid that remains at rest. It represents the potential energy per unit volume of the fluid due to the molecular collisions and thermal motion of the fluid particles.

- Velocity Pressure (q or dynamic pressure): Velocity pressure is the kinetic energy per unit volume of a fluid in motion. It represents the kinetic energy associated with the fluid's velocity and is a measure of the pressure required to bring the fluid to a stop.

In an incompressible fluid (e.g., liquids and low-speed gases), the total pressure (Pt) at any point in the flow can be expressed as the sum of the static pressure (P) and the velocity pressure (q):

Pt = P + q

Mathematically, the velocity pressure (q) is calculated using the formula:

q = 0.5 * ρ * V^2

Where: q = Velocity pressure (dynamic pressure) ρ = Density of the fluid V = Velocity of the fluid

In this equation, the velocity pressure is directly proportional to the square of the fluid velocity. This means that as the fluid velocity increases, the velocity pressure increases at a much higher rate.

As the fluid flows through a system, the total pressure remains constant (according to Bernoulli's principle for incompressible fluids). When the fluid velocity increases (e.g., due to the narrowing of the flow passage), the velocity pressure increases, and the static pressure decreases. Conversely, when the fluid velocity decreases (e.g., due to expanding the flow passage), the velocity pressure decreases, and the static pressure increases.

The balance between static pressure and velocity pressure is critical in various fluid flow applications, such as aerodynamics, HVAC system design, and hydraulic engineering. Understanding this relationship helps engineers optimize flow systems for efficient and safe operation.

Static pressure in the HVAC system

In an HVAC (Heating, Ventilation, and Air Conditioning) system, static pressure refers to the pressure exerted by the air on the walls of the ductwork, filters, coils, and other components when the air is not in motion or is moving at a constant velocity. It is a critical parameter in HVAC design and operation as it directly impacts the system's efficiency, airflow distribution, and overall performance.

Static pressure is typically measured in inches of water column (inH2O) or pascals (Pa). HVAC professionals often measure two types of static pressure:

- Supply Static Pressure: This is the static pressure measured on the supply side of the HVAC system. It represents the pressure exerted by the air as it is pushed through the ductwork and supply vents to deliver conditioned air to the different areas or zones in the building.

- Return Static Pressure: This is the static pressure measured on the return side of the HVAC system. It represents the pressure exerted by the air as it is pulled back through the return vents and ducts to the air handler or furnace for reconditioning.

The ideal static pressure range for an HVAC system is typically between 0.1 to 0.5 inches of water column (inH2O) for residential systems and slightly higher for commercial systems, often between 0.2 to 1.0 inches of water column (inH2O). Staying within this recommended range is crucial for the following reasons:

- Efficient Airflow: Proper static pressure ensures that the HVAC system delivers the designed airflow to conditioned spaces, providing adequate heating or cooling and maintaining comfort.

- Energy Efficiency: Operating within the ideal static pressure range reduces the system's energy consumption as the fans and blowers work efficiently to move air through the ducts.

- Balanced System: Balanced static pressure between the supply and return sides ensures that the HVAC system maintains a stable and balanced airflow, preventing issues like hot and cold spots.

- Equipment Longevity: Correct static pressure reduces strain on HVAC components, extending their lifespan and reducing the frequency of repairs.

- Air Quality: Maintaining proper static pressure ensures that the air filters perform effectively, helping to improve indoor air quality by capturing contaminants.

To monitor static pressure, HVAC technicians use pressure gauges or digital manometers at strategic points in the ductwork, close to the air handler, and at various vents and returns. Regular measurement and adjustment of static pressure are part of routine HVAC maintenance to ensure optimal performance and comfort for building occupants.

Fig 6. Static pressure in an HVAC system

What is the ideal static pressure range for an HVAC system?

The ideal static pressure range for an HVAC (Heating, Ventilation, and Air Conditioning) system depends on the specific design and equipment used, as well as the intended application and system configuration. Generally, HVAC systems are designed to operate within specific static pressure limits to ensure efficient performance, balanced airflow, and minimal strain on the equipment.

For residential HVAC systems, the typical static pressure range is often between 0.1 inches of water column (inH2O) to 0.5 inH2O. In commercial and larger HVAC systems, the static pressure range may vary, but it is commonly between 0.2 inH2O to 1.0 inH2O.

Static pressure measurements are usually taken at critical points in the HVAC system, including

- Supply ducts: To ensure that sufficient airflow is being delivered to various zones and rooms.

- Return ducts: To verify proper air return and maintain a balanced system.

- Air handling unit (AHU): To assess the overall performance of the AHU and identify any restrictions or inefficiencies.

- Filter locations: To monitor filter cleanliness and determine the pressure drop across the filters.

- Fan inlet and outlet: To evaluate the performance and efficiency of the fan.

HVAC system manufacturers provide recommended static pressure guidelines for their equipment, and HVAC professionals typically follow these guidelines during installation, commissioning, and maintenance. Proper static pressure ensures that the HVAC system operates at its designed capacity, delivers the required airflow to conditioned spaces, and minimizes energy consumption.

If the static pressure is too low, it may indicate inadequate airflow, which can lead to reduced heating or cooling capacity and uneven temperature distribution. On the other hand, if the static pressure is too high, it can strain the fan motor, reduce airflow, and increase energy consumption.

Regular monitoring and maintenance of the HVAC system, including checking static pressure, are essential to ensure its optimal performance and energy efficiency. It is best to consult with a qualified HVAC professional to determine the specific ideal static pressure range for a particular HVAC system based on its design, equipment, and intended application.

How does high static pressure impact an HVAC system?

High static pressure in an HVAC (Heating, Ventilation, and Air Conditioning) system can have several negative impacts on its performance, efficiency, and overall operation. When the system operates with static pressure beyond the recommended range, the following issues may arise:

- Reduced Airflow: High static pressure restricts the flow of air through the ductwork and components, resulting in reduced airflow to conditioned spaces. This can lead to inadequate heating or cooling, resulting in discomfort for building occupants.

- Uneven Temperature Distribution: Insufficient airflow caused by high static pressure can lead to uneven temperature distribution within the building. Some areas may be too hot, while others remain too cold.

- Overworked HVAC Equipment: The system's fan, blower, and other components have to work harder to overcome the increased resistance, which can lead to excessive wear and tear, higher energy consumption, and increased maintenance requirements.

- Reduced Efficiency: High static pressure reduces the system's efficiency as it requires more energy to move air through the ducts. This results in higher energy bills and decreased overall energy efficiency.

- Longer HVAC Runtime: The HVAC system may run for longer periods to achieve the desired temperature, leading to increased energy consumption and potentially shortening the equipment's lifespan.

- Strained Fan Motor: The fan motor experiences additional stress when operating against high static pressure, which can lead to premature motor failure.

- Increased Noise: High static pressure can cause noisy operation as the fan works harder to move air through the ducts and components.

- Inadequate Air Filtration: Insufficient airflow due to high static pressure may compromise the system's ability to effectively filter and purify the air, potentially reducing indoor air quality.

- Damaged Ductwork: Prolonged operation at high static pressure can cause ductwork to develop leaks, cracks, or even collapse, leading to further airflow issues and increased repair costs.

To mitigate the impact of high static pressure on an HVAC system, it is essential to identify and address the root causes. HVAC professionals can assess the system's design, ductwork layout, air distribution, and component performance to optimize static pressure within the recommended range. Regular maintenance, including cleaning filters and checking ductwork for obstructions, is also crucial to prevent and address high static pressure issues. Properly sized and designed ductwork, appropriate fan selection, and correct equipment installation are key factors in maintaining the ideal static pressure and ensuring the HVAC system operates at its best efficiency while delivering comfortable and balanced airflow.

Can static pressure be negative?

Yes, static pressure can be negative in certain situations and specific contexts. In fluid mechanics and aerodynamics, pressure is often measured relative to a reference pressure, which can result in positive or negative values.

When pressure is measured relative to atmospheric pressure, it is called gauge pressure. If the pressure is higher than atmospheric pressure, it is considered positive gauge pressure. Conversely, if the pressure is lower than atmospheric pressure, it is considered negative gauge pressure, often referred to as a vacuum.

For example

- Absolute Pressure: This is the total pressure exerted by a fluid, including atmospheric pressure. In this context, static pressure cannot be negative, as it is always measured relative to absolute zero pressure.

- Gauge Pressure: In many practical applications, pressure is measured relative to atmospheric pressure, which is considered the reference point. In this case, if the static pressure is lower than atmospheric pressure, it is recorded as a negative value, indicating a vacuum.

- Differential Pressure: In fluid flow systems, differential pressure is often used to measure pressure differences between two points. If the static pressure at one point is higher than at another point, the differential pressure will be positive. Conversely, if the static pressure at one point is lower than at another point, the differential pressure will be negative.

In HVAC systems, for example, negative static pressure can be observed when the pressure inside a return duct is lower than atmospheric pressure. This may occur if there is a restriction or blockage in the return duct, causing a suction effect that lowers the pressure.

It's essential to consider the reference point when dealing with pressure measurements to understand whether the static pressure is positive or negative. In many cases, negative static pressure or vacuum conditions are carefully managed and controlled for specific applications, such as in vacuum systems, industrial processes, or research and laboratory environments.

Which parameter can cause an effect on static pressure?

Several parameters can affect static pressure in a fluid flow system. Each of these parameters plays a significant role in determining the static pressure level within the system. Here are the key parameters and their effects on static pressure:

- Fluid Velocity: Fluid velocity is a critical factor influencing static pressure. As the fluid velocity increases, the dynamic pressure (velocity pressure) also increases due to the higher kinetic energy of the moving fluid. According to Bernoulli's principle, which describes the energy conservation in a fluid flow, an increase in dynamic pressure is accompanied by a decrease in static pressure. Conversely, a decrease in fluid velocity results in lower dynamic pressure and an increase in static pressure.

- Duct Size and Shape: The size and shape of the duct or flow passage directly impact the static pressure. Smaller and more restrictive ducts generate higher frictional losses, leading to increased static pressure drop along the flow path. Additionally, ducts with irregular shapes or sudden contractions and expansions cause turbulence, which further contributes to pressure losses and affects static pressure.

- Duct Length: Longer duct runs result in more extensive contact between the flowing fluid and the duct walls, leading to higher frictional losses and, subsequently, higher static pressure drop along the length of the duct.

- Obstructions and Bends: Objects like bends, elbows, dampers, valves, and other obstructions within the flow path create resistance to the fluid flow, causing pressure losses and affecting static pressure. Sharp bends and abrupt changes in the direction of the fluid flow can result in higher pressure losses.

- Fluid Density: The density of the fluid affects the static pressure. Incompressible fluids, like water, exhibit changes in static pressure mainly due to variations in velocity and frictional losses. For compressible fluids, like air or gases, the density can vary significantly with changes in pressure and temperature, leading to more complex static pressure behaviors.

- Fluid Viscosity: Fluid viscosity influences the level of internal friction in the fluid. High-viscosity fluids experience more internal resistance, leading to higher pressure losses and affecting static pressure.

- Altitude and Atmospheric Pressure: Changes in altitude and atmospheric pressure have a direct impact on the reference static pressure. At higher altitudes, atmospheric pressure is lower, which affects the baseline static pressure measurement. In some cases, the atmospheric pressure can be considered when calculating gauge pressure.

- Fan or Blower Performance: The performance characteristics of the fans or blowers in the system, such as flow rate, fan curve, and static pressure capability, influence the static pressure at various points in the system. Insufficient fan capacity or incorrect fan selection can result in inadequate static pressure to overcome system resistance.

Understanding how each parameter affects static pressure helps engineers and designers optimize fluid flow systems, ensure proper airflow distribution, and maintain efficient operation in various applications, including HVAC, ventilation, industrial processes, and aerospace engineering.

What are the typical causes of low and high static pressure in a system?

The static pressure in a fluid flow system can deviate from the ideal range due to various factors. Here are the typical causes of low and high static pressure in a system:

Causes of Low Static Pressure:

- Undersized Ductwork: Ducts that are too small for the required airflow can result in high resistance and low static pressure, leading to inadequate airflow to conditioned spaces.

- Air Leaks: Air leaks in the ductwork can lead to loss of air pressure, reducing the static pressure within the system.

- Clogged Air Filters: Dirty or clogged air filters restrict airflow, causing low static pressure and reducing the system's efficiency.

- Duct Blockages: Obstructions in the ductwork, such as debris or closed dampers, can impede airflow, leading to low static pressure.

- Incorrect Fan or Blower Settings: Improper fan speed settings or incorrect blower motor configurations can result in insufficient air movement and reduced static pressure.

- Fan Motor Issues: Faulty or worn-out fan motors may not provide enough power to generate adequate static pressure.

- Damaged Ductwork: Leaky or damaged ducts can allow air to escape, reducing the static pressure in the system.

- Faulty Air Handling Unit (AHU): Issues with the AHU, such as worn belts or pulleys, can affect airflow and cause low static pressure.

Causes of High Static Pressure:

- Restrictive Ductwork: Ducts with small or irregular shapes, excessive bends, or significant obstructions can create high resistance to airflow, resulting in high static pressure.

- Closed or Blocked Dampers: Improperly adjusted or closed dampers restrict airflow and contribute to high static pressure.

- Overloaded Filters: Severely clogged filters increase pressure drop and lead to high static pressure.

- Fan Speed Too High: If the fan or blower is set to an excessively high speed, it can generate more pressure than necessary, causing high static pressure.

- Incorrectly Sized Fan: A fan that is too powerful for the system can create excessive pressure, leading to high static pressure.

- Misaligned or Damaged Fan Blades: Damaged or misaligned fan blades can disrupt airflow, resulting in increased static pressure.

- Closed Vents: Closing too many supply or return vents can create excessive pressure buildup in the ductwork.

- System Imbalance: A mismatch between the supply and return airflow rates can lead to high static pressure.

Both low and high static pressure can have detrimental effects on an HVAC system's performance, efficiency, and comfort. Regular maintenance, proper design, and correct sizing of components are essential to maintain the static pressure within the recommended range and ensure optimal system operation. HVAC professionals should conduct periodic inspections, measure static pressure, and address any issues promptly to avoid potential problems and improve system efficiency.

Why is it essential to consider static pressure when designing ventilation systems?

Considering static pressure is essential when designing ventilation systems for several critical reasons:

- Efficient Air Distribution: Properly designed static pressure ensures that the ventilation system delivers the required airflow to each area or room in the building. By maintaining balanced static pressure throughout the ductwork, the system can efficiently distribute conditioned air and provide consistent comfort to occupants.

- Energy Efficiency: An HVAC system operating at the correct static pressure consumes less energy. When the system operates within the recommended static pressure range, fans and blowers work optimally, resulting in lower energy consumption and reduced operating costs.

- Adequate Airflow: Designing ventilation systems with appropriate static pressure ensures that there is enough airflow to effectively remove indoor pollutants, control humidity, and maintain indoor air quality (IAQ). Adequate airflow is essential for a healthy and comfortable indoor environment.

- Proper Equipment Sizing: Considering static pressure allows for accurate selection and sizing of HVAC components, such as fans, blowers, and ducts. Properly sized equipment ensures that the system can handle the required airflow with minimal strain on the components, promoting longevity and reliability.

- Avoiding Airflow Issues: Inadequate static pressure can lead to airflow problems, such as insufficient airflow to conditioned spaces or excessive pressure drops across filters and ductwork. These issues can result in discomfort, uneven temperature distribution, and compromised IAQ.

- Preventing Equipment Failures: Operating a ventilation system with either excessively high or low static pressure can strain the HVAC equipment. High static pressure may overload the fan motor and cause premature failure, while low static pressure can result in inefficient operation and potential wear on components.

- Temperature Control: Proper static pressure design helps maintain consistent temperatures throughout the building. It ensures that heated or cooled air reaches all areas evenly, preventing hot or cold spots.

- Indoor Comfort: Well-designed ventilation systems with appropriate static pressure contribute to improved indoor comfort for occupants. Properly distributed airflow helps maintain the desired temperature and humidity levels, promoting a comfortable environment.

- Noise Reduction: Correct static pressure design reduces the likelihood of noisy operation. By optimizing airflow rates, the system operates more quietly, enhancing the overall indoor environment.

- Regulatory Compliance: Building codes and energy efficiency standards often include guidelines related to ventilation system design and static pressure. Ensuring compliance with these regulations is crucial for legal and safety reasons.

In summary, considering static pressure during ventilation system design is fundamental for achieving efficient and effective operation. Properly designed ventilation systems with appropriate static pressure improve IAQ, energy efficiency, equipment performance, and overall occupant comfort, making them essential for any well-designed building HVAC system.

Fig 7. Pressure scales

What is static pressure used for?

Static pressure is used for various purposes in engineering, fluid mechanics, and practical applications across different industries. Some of the key uses of static pressure include

- HVAC System Design: In heating, ventilation, and air conditioning (HVAC) systems, static pressure is critical for designing and sizing ductwork, selecting fans, and ensuring proper airflow distribution throughout the building.

- Aerodynamics and Aerospace Engineering: In aerodynamics and aerospace engineering, static pressure measurements are essential for analyzing aircraft performance, airfoil design, and aerodynamic forces on vehicles.

- Building Ventilation: Static pressure is used to design ventilation systems in buildings, ensuring proper air exchange, filtration, and maintaining indoor air quality (IAQ).

- Industrial Ventilation: In industrial settings, static pressure is considered in designing ventilation systems for worker safety, controlling contaminants, and maintaining air quality.

- Fluid Flow Analysis: Static pressure measurements are used to study fluid flow in pipes, ducts, and channels, helping optimize flow rates, pressure drops, and system efficiency.

- Barometric Pressure: Meteorologists use static pressure measurements to monitor and forecast weather patterns, including changes in barometric pressure.

- Air Pressure Regulation: Static pressure is used in air pressure regulators and control systems to maintain specific pressure levels in pneumatic systems and equipment.

- Wind Tunnel Testing: In wind tunnel testing, static pressure measurements are taken to evaluate aerodynamic models and assess airflow patterns.

- Hydraulic Systems: In hydraulic engineering, static pressure is considered in the design and analysis of pipelines, pumps, and hydraulic systems.

- Filtration and Air Purification: Static pressure measurements are relevant in air filtration and purification systems to assess filter performance and pressure drop.

- Gas Storage and Distribution: In gas storage tanks and pipelines, static pressure is monitored to ensure safe and efficient distribution.

- Medical Devices: In medical equipment like ventilators, static pressure regulation is essential for maintaining precise airflow rates.

- Environmental Monitoring: Static pressure measurements are used in environmental monitoring to study atmospheric pressure changes and weather patterns.

- Laboratory and Research: Static pressure measurements are used in research settings, experiments, and laboratories for various fluid mechanics studies and controlled environments.

Overall, static pressure plays a crucial role in many engineering applications, fluid dynamics, and practical systems, enabling efficient and safe operation across a wide range of industries and scientific disciplines.

Fig 8. The common use of static pressure

A real example of static pressure in the industry

A real example of static pressure in the industry can be found in HVAC systems, specifically in the context of designing and analyzing the performance of an air conditioning ductwork network.

In a commercial building, the HVAC system is responsible for providing heating, ventilation, and air conditioning to maintain a comfortable indoor environment for occupants. To achieve this, a network of ducts is used to distribute conditioned air from the air handling unit (AHU) to different areas or zones within the building.

In this example, static pressure is a critical parameter that HVAC engineers consider during the design and commissioning of the HVAC system. They measure static pressure at various points within the ductwork to ensure that the system operates within the desired range.

Real-world scenario:

Let's consider an office building with multiple floors and different zones. The AHU is located in the basement, and conditioned air is supplied to each floor through a network of ducts. Each floor has return air grilles that allow the air to return to the AHU for reconditioning.

During the design phase, engineers calculate the required airflow rates for each zone based on factors like room size, occupancy, and heat load. They then size the ducts appropriately to handle the required airflow.

Once the system is installed, technicians conduct a commissioning process where they measure static pressure at various critical points in the ductwork. This includes measuring static pressure at supply registers, return grilles, near bends or obstructions, and close to the AHU.

The measured static pressure values are compared to the design specifications, and adjustments are made if necessary. If the static pressure is too low, it may indicate undersized ducts or airflow restrictions, requiring adjustments to increase airflow. On the other hand, if the static pressure is too high, it may indicate overly restrictive ducts or blockages, requiring adjustments to reduce resistance and improve airflow.

By ensuring that static pressure is within the desired range, the HVAC system can deliver the required airflow to all areas, provide optimal heating or cooling, and maintain comfortable indoor conditions for the building occupants. Properly managed static pressure also helps prevent equipment strain, optimize energy efficiency, and extend the lifespan of the HVAC components.

Static pressure types

In fluid mechanics and engineering, two primary types of static pressure are commonly encountered:

- Absolute Pressure (Pabs): Absolute pressure is the total pressure exerted by a fluid, including both the static pressure and the dynamic pressure (velocity pressure) due to the fluid's motion. It is measured relative to a perfect vacuum, which means that absolute pressure includes atmospheric pressure as well.

Mathematically, absolute pressure (Pabs) is expressed as:

Pabs = Patm + Pstatic + Pdynamic

Where: Patm = Atmospheric pressure (pressure of the surrounding air) Pstatic = Static pressure (pressure when the fluid is at rest) Pdynamic = Dynamic pressure (pressure due to fluid motion)

- Gauge Pressure (Pg): Gauge pressure is the pressure measured relative to atmospheric pressure. It represents the difference between the absolute pressure and the atmospheric pressure at a specific location.

Mathematically, gauge pressure (Pg) is expressed as

Pg = Pabs - Patm

Since gauge pressure is measured relative to atmospheric pressure, it can be positive or negative. When the gauge pressure is positive, it indicates that the absolute pressure is greater than the atmospheric pressure. Conversely, when the gauge pressure is negative, it means that the absolute pressure is less than atmospheric pressure, and the pressure is in a vacuum.

Gauge pressure is commonly used in various applications, especially in systems where pressure changes are of interest, such as in HVAC systems, tire pressure measurements, and industrial pressure gauges.

It is essential to understand the distinction between absolute pressure and gauge pressure, as it affects how pressure is measured, reported, and used in various engineering calculations.

Fig 9. Static pressure

Comparing tables

| Parameter | Absolute Pressure (Pabs) | Gauge Pressure (Pg) |

| Definition | Total pressure, including atmospheric pressure and static & dynamic pressures | Pressure measured relative to atmospheric pressure |

| Reference Point | Vacuum (zero pressure) | Atmospheric pressure |

| Mathematically | Pabs = Patm + Pstatic + Pdynamic | Pg = Pabs - Patm |

| Range | Positive and can be zero | Can be positive or negative |

| Significance | Used in fluid dynamics, thermodynamics, and absolute pressure measurement | Commonly used in pressure gauges, tire pressure, HVAC systems, and most pressure measurements on Earth |

| Unit | Typically measured in pascals (Pa), psi, bar, etc. | Typically measured in pascals (Pa), psi, bar, etc. |

Please note that this is a simplified representation, and there are various unit conversions and specific applications where these pressure types are used. The choice of using absolute or gauge pressure depends on the context and requirements of the specific engineering or scientific application.

How is static pressure different from dynamic pressure?

Static pressure and dynamic pressure are two distinct components of the total pressure in a fluid flow system. They represent different aspects of pressure in a fluid, and their contributions combine to make up the total pressure at a given point in the flow. Here are the key differences between static pressure and dynamic pressure:

- Definition:

- Static Pressure (Pstatic): Static pressure is the pressure exerted by a fluid that remains at rest. It represents the potential energy per unit volume of the fluid due to the molecular collisions and thermal motion of the fluid particles. In other words, it is the pressure that the fluid exerts when it is not in motion.

- Dynamic Pressure (Pdynamic or q): Dynamic pressure, also known as velocity pressure, is the kinetic energy per unit volume of a fluid in motion. It represents the pressure associated with the fluid's velocity and is a measure of the pressure required to bring the fluid to a stop.

- Reference Point:

- Static Pressure: Static pressure is measured relative to a reference point, which is typically a vacuum or zero pressure.

- Dynamic Pressure: Dynamic pressure is measured relative to the surrounding static pressure of the fluid.

- Formula:

- Static Pressure: Static pressure is constant and is not affected by the fluid's velocity. It is given by the formula Pstatic = Ptotal - Pdynamic, where Ptotal is the total pressure at a point in the flow (sum of static pressure and dynamic pressure).

- Dynamic Pressure: Dynamic pressure is directly proportional to the square of the fluid velocity. It is calculated using the formula Pdynamic = 0.5 * ρ * V^2, where ρ is the fluid density, and V is the fluid velocity.

- Significance:

- Static Pressure: Static pressure is crucial in many engineering applications, including HVAC system design, building ventilation, aerodynamics, and fluid flow analysis. It helps determine the resistance to fluid flow in a system and is essential for optimizing system efficiency and performance.

- Dynamic Pressure: Dynamic pressure is essential for understanding the impact of fluid velocity on a system. It plays a significant role in aerodynamics, aircraft design, wind engineering, and other fields where fluid motion is a critical factor.

- Measuring Instruments:

- Static Pressure: Static pressure is typically measured using pressure gauges or manometers.

- Dynamic Pressure: Dynamic pressure can be measured using specialized instruments like pitot tubes or pressure sensors placed in areas where the fluid is in motion.

In summary, static pressure and dynamic pressure are distinct components of the total pressure in a fluid flow system. Static pressure represents the pressure when the fluid is at rest, while dynamic pressure represents the pressure due to fluid motion. Together, they provide a comprehensive understanding of the pressure distribution in a fluid flow and play vital roles in various engineering applications.

Conclusion

In conclusion, static pressure is a fundamental concept in fluid mechanics and aerodynamics. It refers to the pressure of a fluid when it is at rest or moving at a constant velocity, unrelated to its motion. Static pressure is essential in various engineering applications, including aerodynamics, HVAC design, and building ventilation systems.

It is distinct from dynamic pressure, which is related to the fluid's velocity, and together with dynamic pressure, it forms the total pressure in a fluid flow. Static pressure remains constant at a specific point in the flow and is measured using pressure gauges or manometers.

The understanding of static pressure is crucial in designing efficient systems and structures, optimizing airflow, and calculating fluid behavior in various engineering and scientific contexts. Overall, static pressure is a key parameter that influences the performance and behavior of fluids in both stationary and moving scenarios.

To recap

- What is static pressure in fluid mechanics?

Static pressure is the pressure exerted by a fluid when it is at rest or moving at a constant velocity. It is the pressure experienced by an object immersed in the fluid and is unrelated to the fluid's velocity.

- How is static pressure different from dynamic pressure?

Static pressure is the pressure of a fluid at rest, while dynamic pressure is related to the fluid's motion and is caused by its velocity. The total pressure at a point in a fluid flow is the sum of static and dynamic pressures.

- What is the significance of static pressure in aerodynamics?

In aerodynamics, static pressure plays a crucial role in determining the lift and drag forces on an aircraft. It helps engineers design aircraft wings and optimize their shape to achieve desired flight characteristics.

- How is static pressure measured?

Static pressure is often measured using pressure gauges or manometers. These devices provide the pressure reading at a specific point in the fluid, such as inside a pipe, a wind tunnel, or an aircraft.

- Does static pressure change with fluid velocity?

No, static pressure remains constant at a specific point in a fluid flow, regardless of the fluid's velocity. It only changes if there are alterations in the fluid's density or temperature.

- What is meant by "stagnation pressure"?

Stagnation pressure, also known as total pressure, is the sum of the static pressure and the dynamic pressure at a specific point in a fluid flow. It represents the pressure when the fluid is brought to a complete stop (zero velocity) by an adiabatic process.

- Can static pressure be negative?

Yes, static pressure can be negative in certain situations, such as when the fluid exerts suction or when the pressure at a particular point in the flow is lower than the atmospheric pressure.

- Why is static pressure important in HVAC systems?

In HVAC (Heating, Ventilation, and Air Conditioning) systems, static pressure is essential for designing efficient ductwork. It helps ensure proper air distribution and prevents issues like reduced airflow or increased energy consumption.

- What is the impact of static pressure on buildings?

Static pressure plays a vital role in building design and ventilation. It determines how air circulates inside a building and influences the efficiency of heating and cooling systems.

- How is static pressure used in fluid dynamics calculations?

Static pressure is commonly used in various fluid dynamics equations, including Bernoulli's equation, which relates static pressure, dynamic pressure, and total pressure in a fluid flow. It is also used to analyze fluid behavior in pipes, channels, and other flow systems.

References

https://www.dekkoi.co/post/static-pressure

https://airfixture.com/glossary/static-pressure

https://hvacrschool.com/use-static-pressure-responsibly/

https://www.mechnflow.com/post/total-pressure-static-pressure-and-dynamic-pressure

https://johncipollone.com/static-pressure-hvac/

https://www.pumpsandsystems.com/three-musketeers-static-pressure-kinetic-energy-and-potential-energy

Recent Posts

-

Booster Pump Troubleshooting and Maintenance: How to Fix and Prevent Common Issues

1. Introduction Imagine turning on your faucet only to be greeted with a weak trickle of water when …22nd Apr 2025 -

Energy-Efficient Booster Pumps: Selection and Tips for Maximizing Performance

1. Introduction Imagine never having to deal with fluctuating water pressure, noisy pumps, or skyroc …19th Apr 2025 -

Booster Pumps for Sustainable Water Systems: Irrigation and Rainwater Harvesting Solutions

1. Introduction Water scarcity is no longer a distant threat—it’s a reality affecting millions …16th Apr 2025