Detecting the Presence and Orientation of Caps of Blood Test-Tubes by Means of Photoelectric Analog Reflex Sensors

Blood test tubes enter the racks using special conveyors. These tubes must be positioned in the correct upward direction; the tubes' caps be facing upward.

But monitoring the blood test tubes is difficult due to the material they contain and their shape. However, instead of using expensive and laborious camera-based systems or profile scanners, we need sensors to detect the presence and orientation of the tubes' caps.

What type of sensor fits this challenge?

Analog reflex sensors with protection class IP67 are appropriate for this challenge.

How do these sensors work?

These sensors detect the mounted cap by its height of 1 mm above the test tube. The controller will checks the sensor's analog signals and determine the cap's position Every 20 ms.

After this detection, the machine will rotate the test tube in the correct direction and push it to the rack. A test tube without a cap is determined to be defective by the sensor because a significant bounce cannot be detected. In this case, the machine will be turned off. This way, the device can process one precisely oriented test tube per second.

Click on photoelectric sensors to view the products for this application.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Checking the Presence of Cans in Cardboard Boxes by Means of Analog Inductive Sensors

Warranting Safe Status of Load before Starting Platform Lift and during Operation Using Inductive Sensors

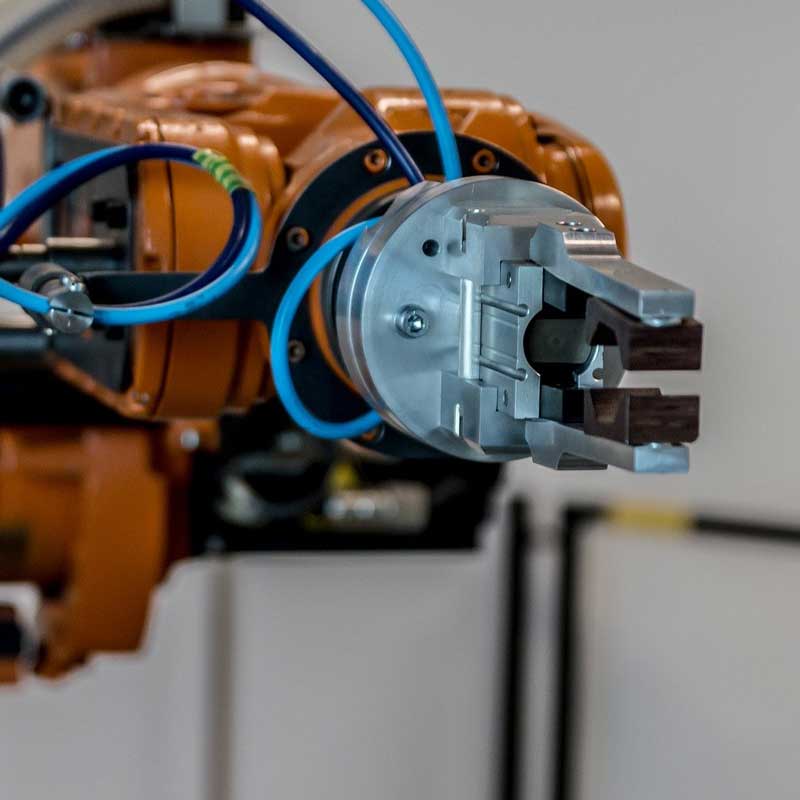

Figuring Out the Jaw Position for High Precision Robot Grippers by Miniature Inductive Sensors

Related Products