Figuring out Clear Plastic Sheets during Thermoforming through Transparent-Object Sensors with Patented UV Technology

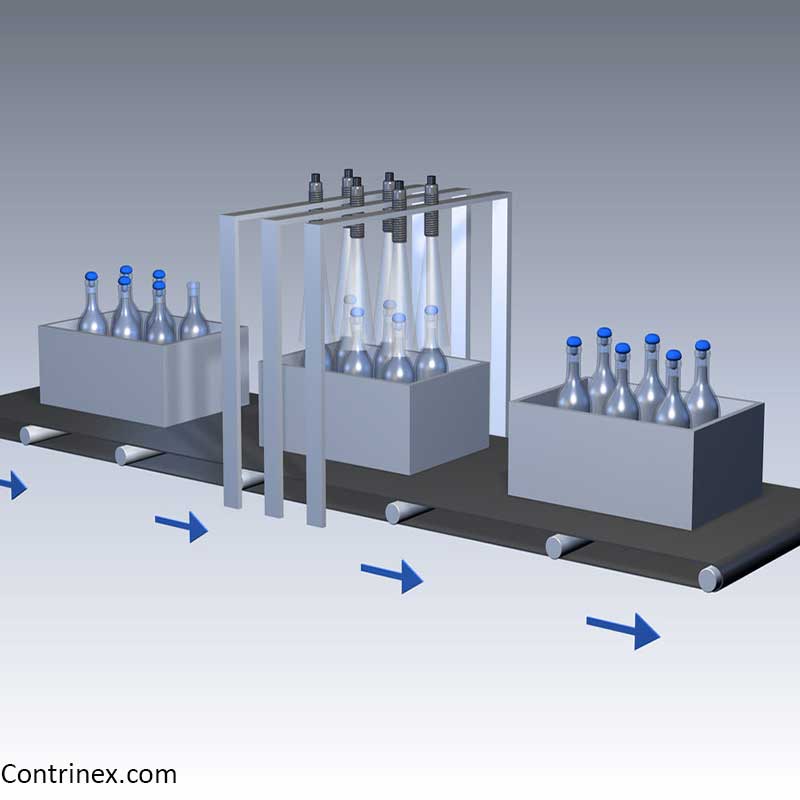

During automated packaging, high- velocity thermoforming lines manufacture transparent plastic blister-trays from continuous reel-stock material.

Sensors must sense the transparent plastic sheets as they are unwound, warranting the material is effectively tensioned as it enters the loading station. Photoelectric sensors using visible-light sources are inappropriate because they can't differentiate between ‘present material’ and ‘not present material’.

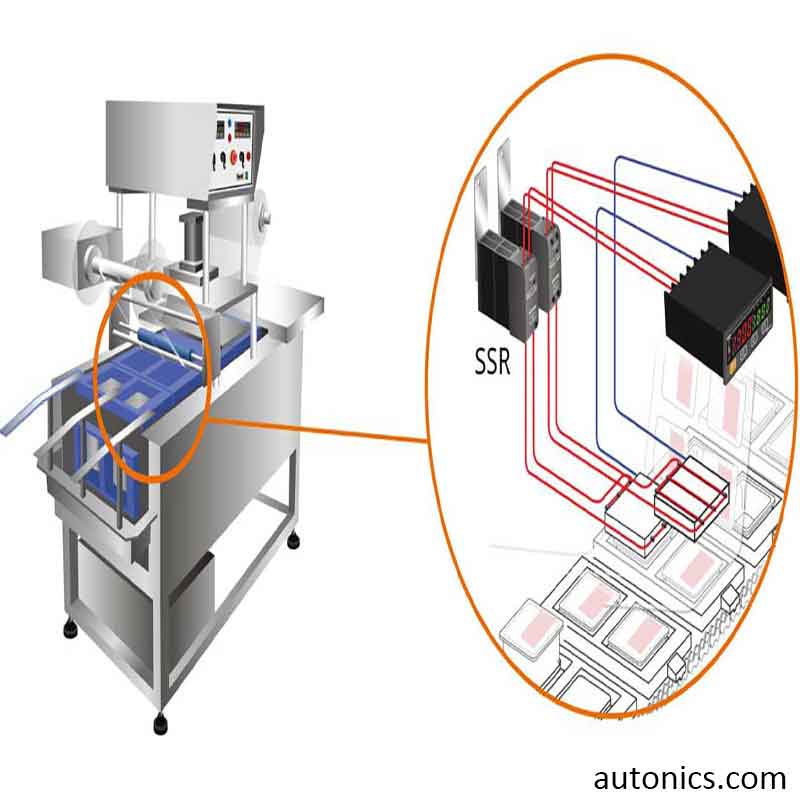

Transparent-object reflex sensors with UV LED-light sources are suitable for this application. Positioning these sensors and reflectors is easy.

Transparent-object sensors make use of a patented reflex working principle with polarized UV light at 275 nm. Their set up is easy and they are optimally flexible.

Furthermore, IO-Link is enabled on PNP versions at no extra cost. Another output sends a stability alarm in the occasion of decreased sensitivity, showing the demand for preventative protection before any performance degradation takes place.

The sensors' vigorous construction, featuring miniature plastic housings with M8 connectors, guarantees dependable operation. They have a detection range as much as 1200 mm. Sensitivity parameters are saved on the sensor’s built-in memory and can be retrieved or up to date remotely through IO-Link, with no need to manual adjustment. It is notable that this solution is fantastically affordable.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Reliable Tool Changing in Packaging Machines by RFID

Detecting Bottle Caps through Cardboard Case on High-Velocity Packaging Lines

Selected Applications From Packaging Industry

Related Products