Flow Measurement in Metallurgy Industry: Orifice Flowmeters

The gases transported throughout the metallurgical process must be measured.

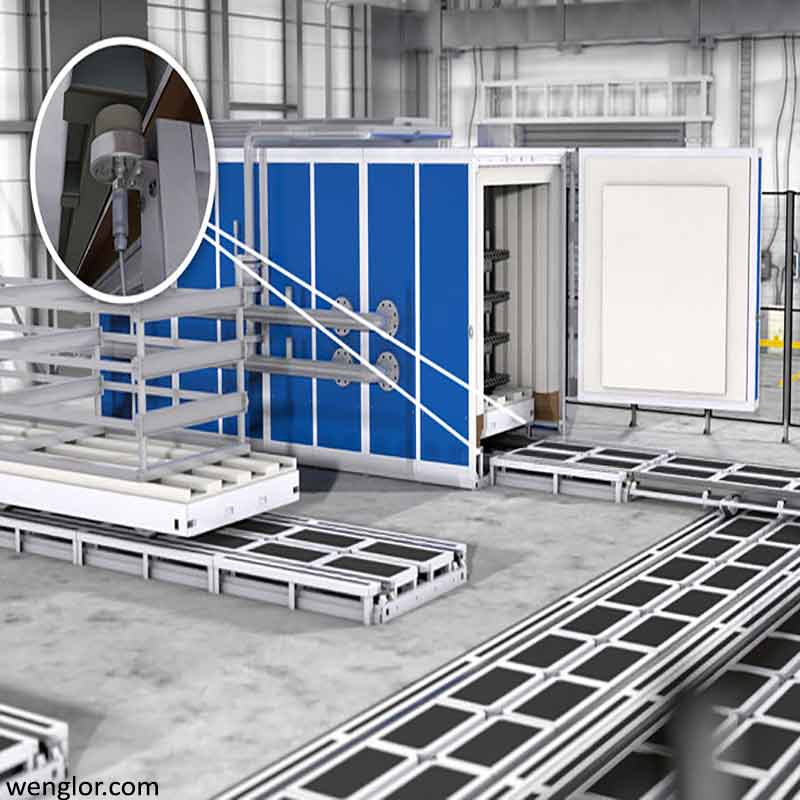

The measured media, however, has lots of impurity materials, the transport pipe has a large diameter, and the pressure port is easy to be blocked. The ordinary flow meter can't measure the gases accurately enough. Various pressure types (orifice) flow meters are suitable for this purpose.

The working principle of orifice flow meters:

When the fluid flows through the throttling element, a pressure difference may be generated on each side of the throttling element. At this time, the flow rate is proportional to the square root of the differential pressure. The flow value corresponding to the differential pressure may be acquired consistent with the applicable formula.

Orifice flow meters can constantly measure the volume flow of different gases, liquids, and vapors.

Some of the Features of Orifice Flow Meters are as follows:

(1) They have Standard throttling element and they require no real flow calibration

(2)They have Simple construction, are easily fixed, highly reliable and stable.

(3) They have a wide application range, and are appropriate for flow measurement of most process media and conditions including single-phase liquids (liquid, gas, steam), some mixed-phase flow, and detection and measurement of working circumstance (temperature measurement, pressure measurement), general manufacturing process pipe diameter, etc.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Inductive Sensors for Extreme Temperature Ranges

Special Inductive Sensors for Figuring out the Baking Trays under High Temperatures

Special Data Loggers for Open-Pit Mines

Related Products