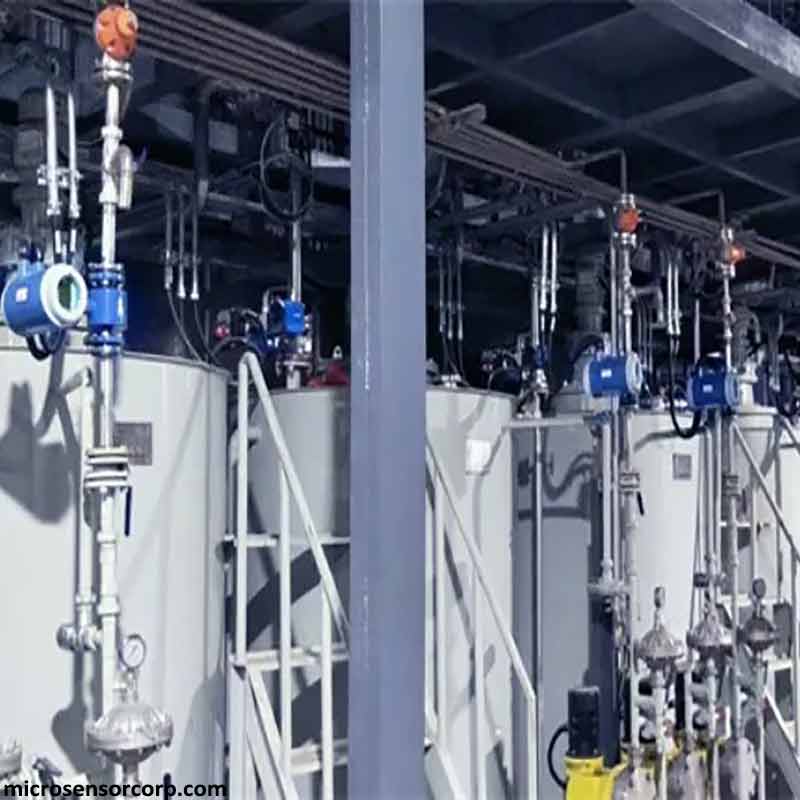

Flow Measurement in the Process of Manufacturing High-End Paper Products

A dosing device is required in the manufacturing procedure of high-end paper merchandise, and distinctive raw materials in the liquid storage tank are added throughout the manufacturing through a metering pump consistent with a certain ratio. Two issues are important in this process:

1. Chemical acid/alkali medium measurement

2. Accurate measurement of small flow

As the raw materials are relatively expensive such as oil repellent and water repellent etc. and the addition amount of each material in the proportioning scheme is relatively small, the flow range of different working conditions requires to be controlled at 60 L/H to 1000 L/H. For a metering pump with 3% accuracy, although the displacement can be measured stably, it is difficult to hard to appropriately and reliably measure the proportion of the added materials. The device used for this purpose ought to fulfill some Requirements:

(1) Different acid-based media in the range of PH2~9

(2) It should have a Small flow rate (minimum tens of L/H)

(3) It should be Accurate in measurement.

(4) It should have Good long-term stability.

Different Customized small diameter flow measurement and control merchandise are now designed for this purpose whose electrodes are made up of tantalum which is suitable for different acid-based media.

Using these products we can realize standardized and smart manufacturing smoothly.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Monitoring the Level of Cartridge in Solder and Adhesive Dispensers via Compact Capacitive Sensors

Air and Aerosol Sampling Pumps for Workplaces

Selected Applications From Chemical, Petrochemical and Refining Industry

Related Products