Identification of Faulty Units during Production of Parking Cables

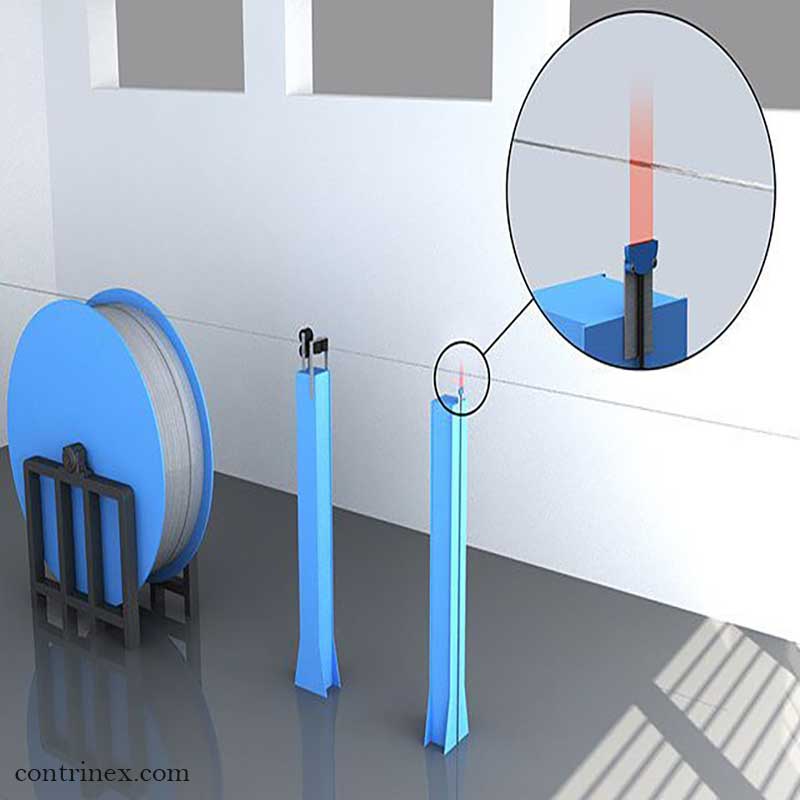

In automotive parking-brake cable manufacturing, twisted threads of steel wire form a cable.

Sometimes, a simple fault in the production process causes the cable to break. A sensor system should identify the cable as it passes from one operation to another. It also should be able to stop the process if it breaks.

The sensor system should be able to detect the cable anywhere within a specified range.

A multi-beam photoelectric sensor system is designed for this application.

Features of the solution:

• Including a DIN-rail-mounted fiber-optic amplifier with a multi-beam diffuse sensing head

• Optimal most switching frequencies and sensing intervals. Consequently, being ideal for diagnosing fast-moving objects

• High mechanical protection due to its PBTP construction of the sensing head

• First set-up via a manual teach-in function and an integral signal-strength LCD

• Operating without any human intervention after the first set-up

• Connection to the customer’s control system via an industry-standard PNP interface and an integral M8 cable connector

• Simple removal and replacement

Note1: These sensors diagnose objects across their whole width. So they supply a detection envelope which fulfills the clients’ demands.

Note2: A fiber cable with optimal length permits faraway boarding of the fiber-optic amplifier.

Click on the category of photoelectric sensors to see related products.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Position Detection of Forklift Forks When Opening Container Lid by Rugged Inductive Sensors

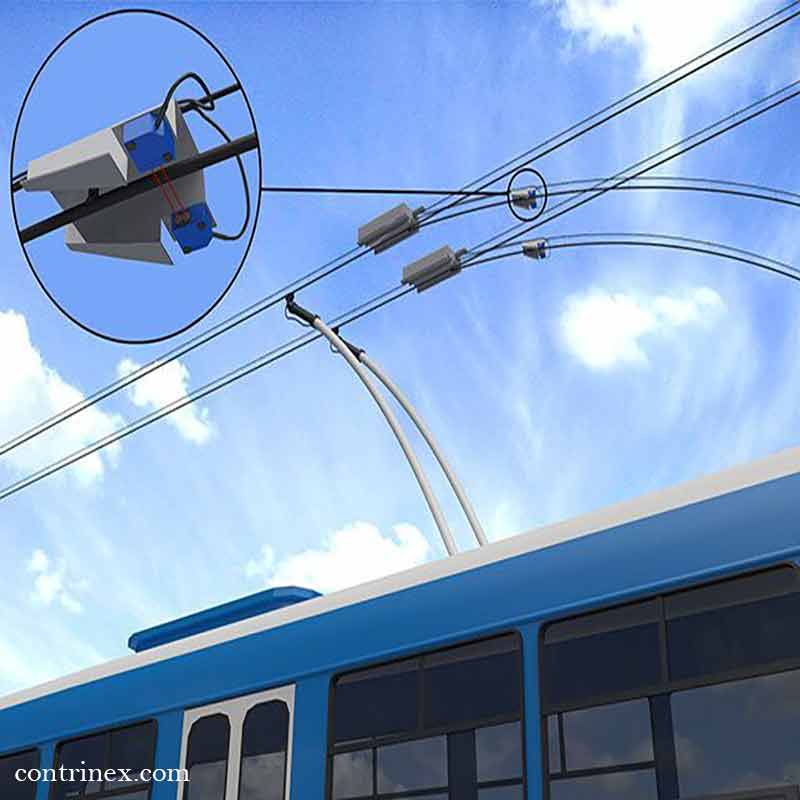

Identification of Trolley-Bus Current Collector by Rugged Photoelectric Sensors

Identification of Incomplete Units by Infrared Light Curtains

Related Products