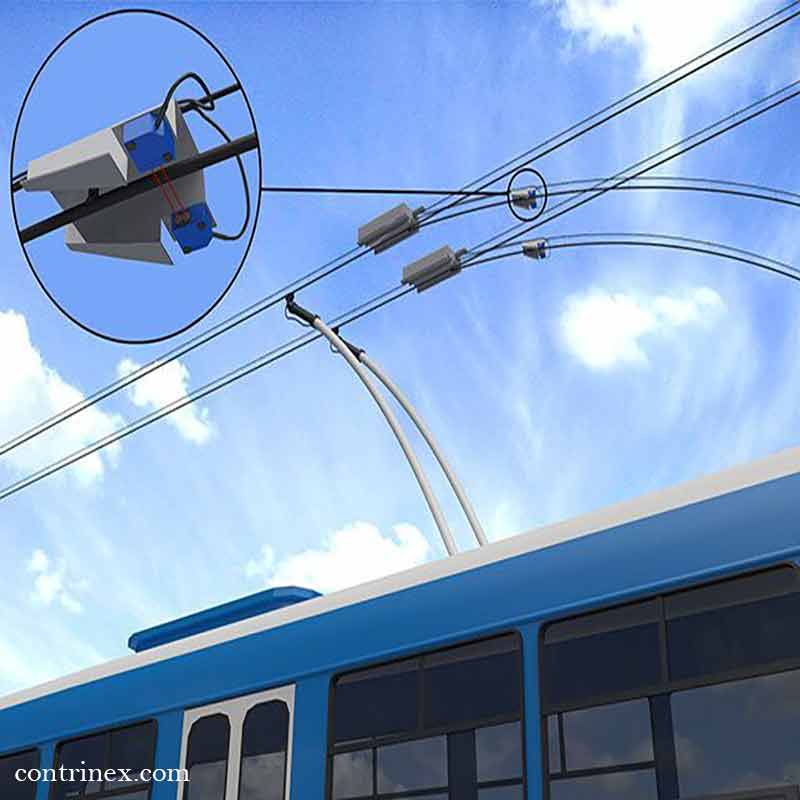

Identification of Trolley-Bus Current Collector by Rugged Photoelectric Sensors

At road junctions, wire switches manage the travel direction of trolleybuses. These switches are installed at the overhead conductor cables.

Sometimes a triggered switch prematurely reverts to the straight-through position. If so, the current collector merges as disengaged. This premature movement will destroy the switch. Operators set up safety systems to prevent premature switching.

During the production of trolleybus control systems, engineers need a reliable, rugged sensor system. Such a system can detect the presence of a current collector as it passes a switch. The system must tolerate diverse outdoor weather conditions.

Solution of the challenge:

Stable, all-electronic through-beam sensors from the photoelectric range are suitable for this application.

Features of the solution:

• Least vulnerability to vibration due to rugged construction and vacuum-encapsulated electronics

• Resistance to harsh environment

• Resistance to accidental damages

• High reliability

• Low maintenance expenses

• Easy replacement of the complete assembly due to The one-piece mounting bracket

How it works:

As the current collector passes between the two units it breaks the beam, triggering the sensor and returning the switch to the straight-through position.

Each unit connects to the trolleybus control systems through a PVC-sheathed cable with a hermetically sealed entry. The receiver has a PNP dark-on interface.

Please click the following link to see the photoelectric sensor category.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Rugged Inductive Sensors for Preventing Overloading Of Hook Lift Truck Arm

Identification of Switch Washers with Inductive Sensors during Their Production

Identification of Incomplete Units by Infrared Light Curtains

Related Products