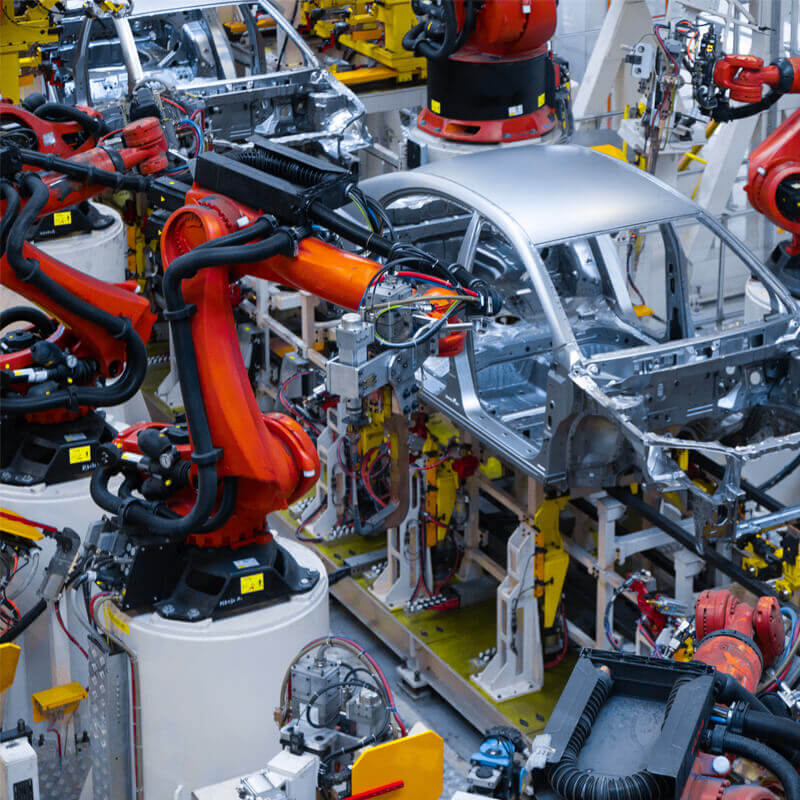

Intrinsically Safe Sensors for Paint Robots in Car Industry

In the process of painting the body of vehicles, especially in the early stages of car manufacturing, glossy body paints imposed a lot of time and money on manufacturers. Rotary atoms, first made in the 1980s and 1990s and also known as the color robot, are very cost-effective. Some types of rotary atoms require only one rotating disk to operate.

Intrinsically safe pressure transmitters and intrinsically safe temperature sensors are designed to be applied in paint robots.

When painting car bodies, even if non-flammable water-based paint is used, the mist is generated during atomization. This mist can cause ignition. The mentioned pressure transmitters and temperature sensors are equipped with explosion-proof technology.

Some pressure transmitters are mounted on the robot spray head and detect rapid pressure changes that can occur through the placement of hoses. The pressure transmitters are located in a high voltage field and communicate with the robot control mechanism through a fiber optic cable. Excess pressure transmitters take axle pumps and dosing systems under observation. They can be linked to the control system via copper conductors.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Pressure Transducers for Paint Pistols

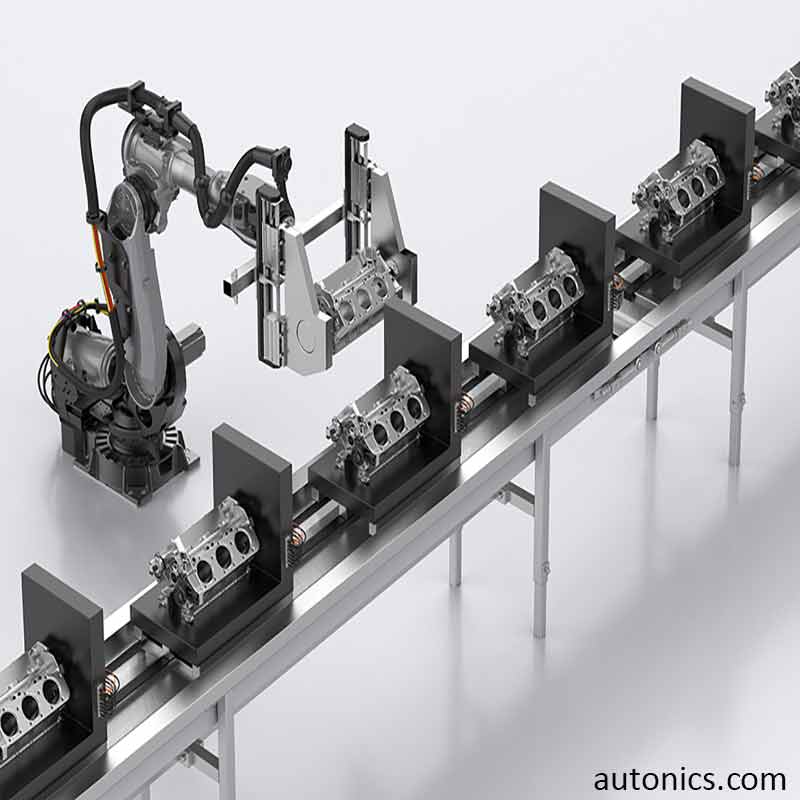

Manufacturing Automobile Components

Position Detection of Forklift Forks When Opening Container Lid by Rugged Inductive Sensors

Related Products