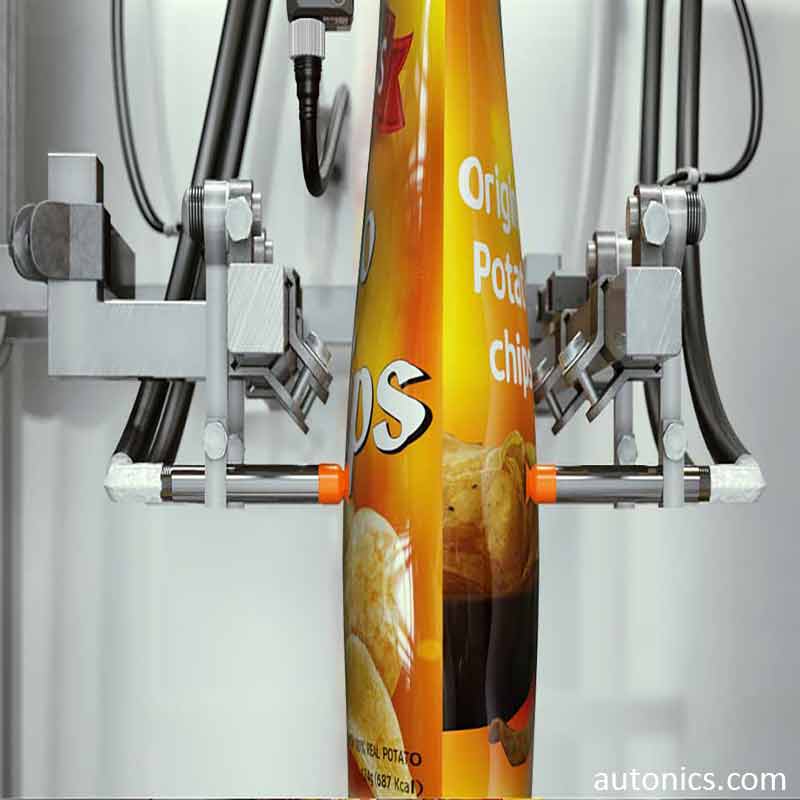

Filling, Sealing and Cutting of Chip Bags

Engineers who want to make the process of sealing and cutting as accurate as possible, can use Color mark sensors. These sensors help them to figure out possible lines on packaging material.

It is vital to be able to estimate pressure throughout the process of suction and inflation of packaging material. For this purpose, engineers can use Compact pressure sensors.

Throughout the process of sealing the bags of potato chip, we must be able to control the temperature of heaters in a fast and reliable way. Single phase power controllers and High performance PID temperature controllers are designed for this purpose.

Fast and reliable controlling of temperature is a critical matter throughout the process of sealing the potato chip bags. Solid state relays with integrated heatsink and Multi-channel modular temperature controllers are appropriate for this application.

Graphic Panels are used for configuration of different parameters and monitoring the status from outside of the control box. Stable energy for temperature controllers and photoelectric sensors is needed. Switching mode power supplies offer this kind of energy.

Key selector switches and lever selector switches have been designed to make us able to shift between AUTO and MANUAL or RUN and STOP modes. However, some switches are needed to halt the machinery in the occasion of emergencies. Emergency switches are appropriate for this application.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

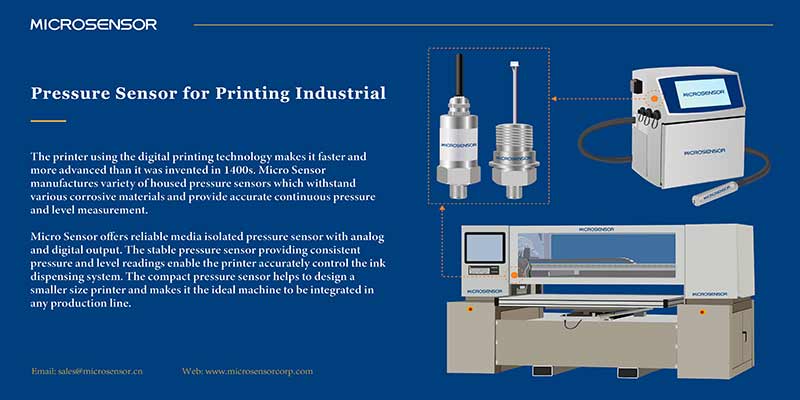

Pressure Sensors in Printing Industry

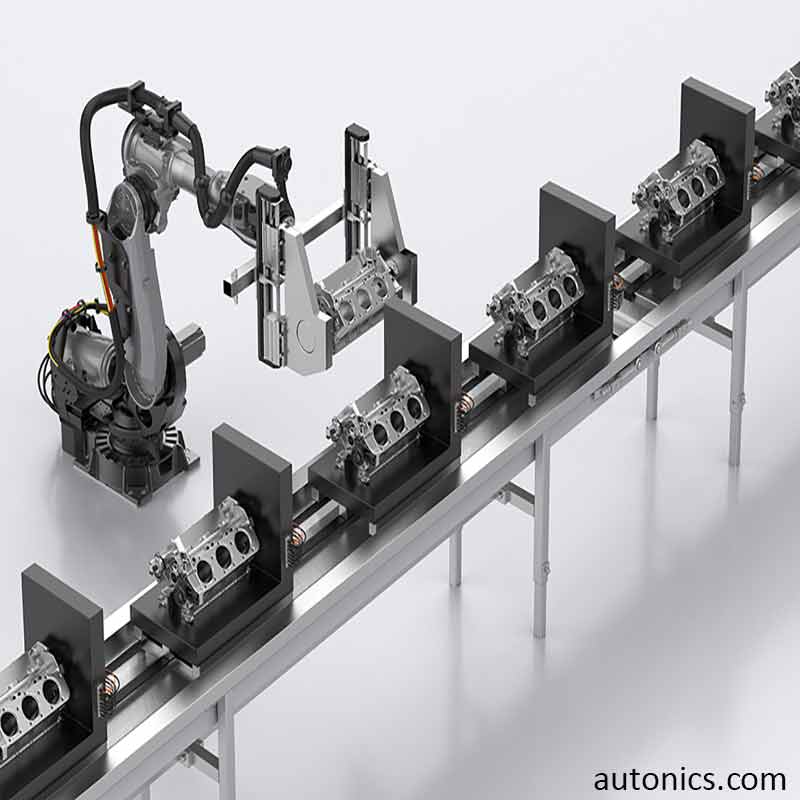

Manufacturing Automobile Components

entry/exit of parking towers

Related Products