Making Employees Safe during Heat Staking in White-Goods Manufacture via Light Curtains

Throughout semi-automated heat staking of assemblies for home white goods, producers use light curtains to preserve employees' protection without compromising manufacturing throughput. Special devices are needed to prevent the press-head from descending in the event that they discover any intrusion in the operating area, halting the working cycle instantly.

Type 2 AOPDs (active optoelectronic protective devices) are suitable and good enough for employees' protection. Designed for applications in which the chance is moderate, light curtains are rated to EN/ISO 13849-1 Category 2, Performance Level PL c and IEC 61508 Safety Integrity Level SIL 1, making them best for this application.

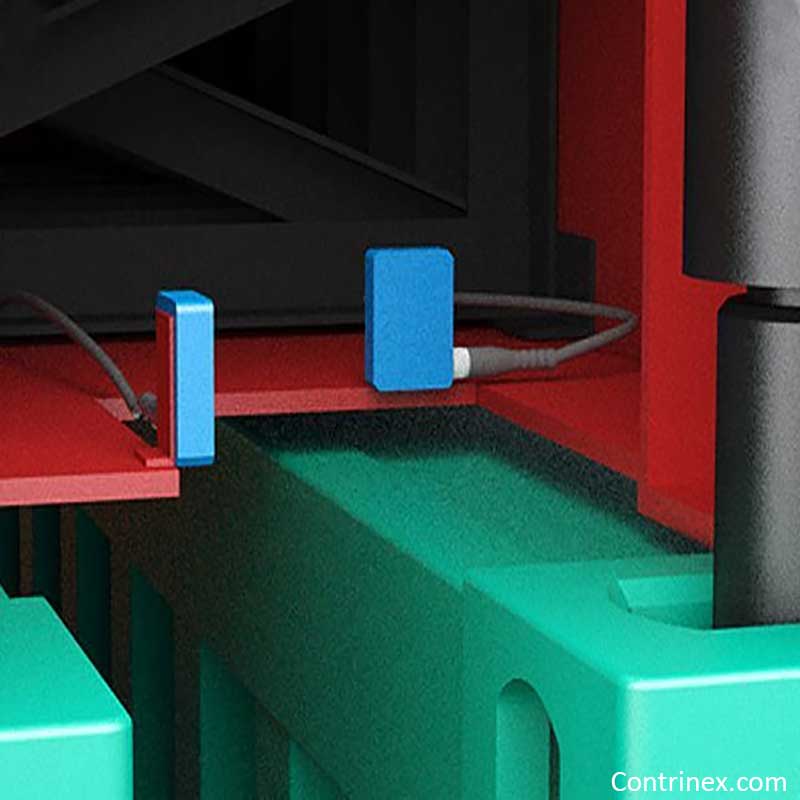

The light curtains have an operating range of up to twelve meters and a resolution of 30 mm; they protect the open front area of the press. Detection height is 795mm.

These devices have rugged aluminum housings and are produced with IP65 + IP67 protection; they can tolerate vibrations and shocks.

Industry-standard PNP normally-open configuration allows connection to the customers' control system through an integral 5-pin M12 cable connector. They have an integrated alignment LED and everlasting autocontrol – a characteristic not commonly found on Type 2 protection tools. These sensors occupy much less space than the mechanical guards.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

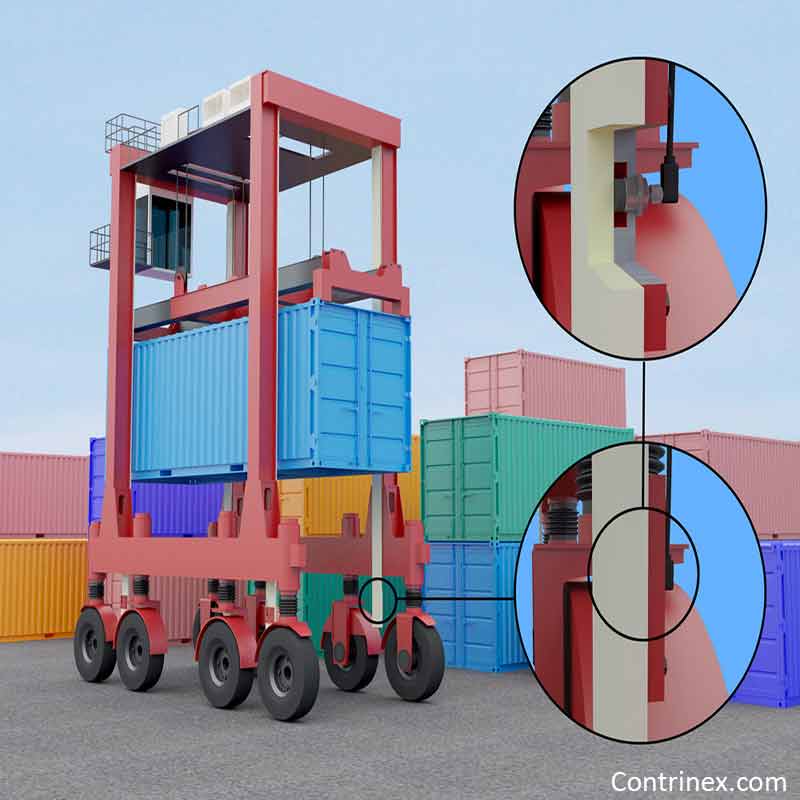

Recognizing the Size of Shipping Containers through High-Stability Photoelectric Sensors

Assessing Wear in Plain Bearings via Rugged Inductive Sensors

Precisely Figuring Out High-Speed Spindles' Direction Using Miniature Inductive Sensors

Related Products