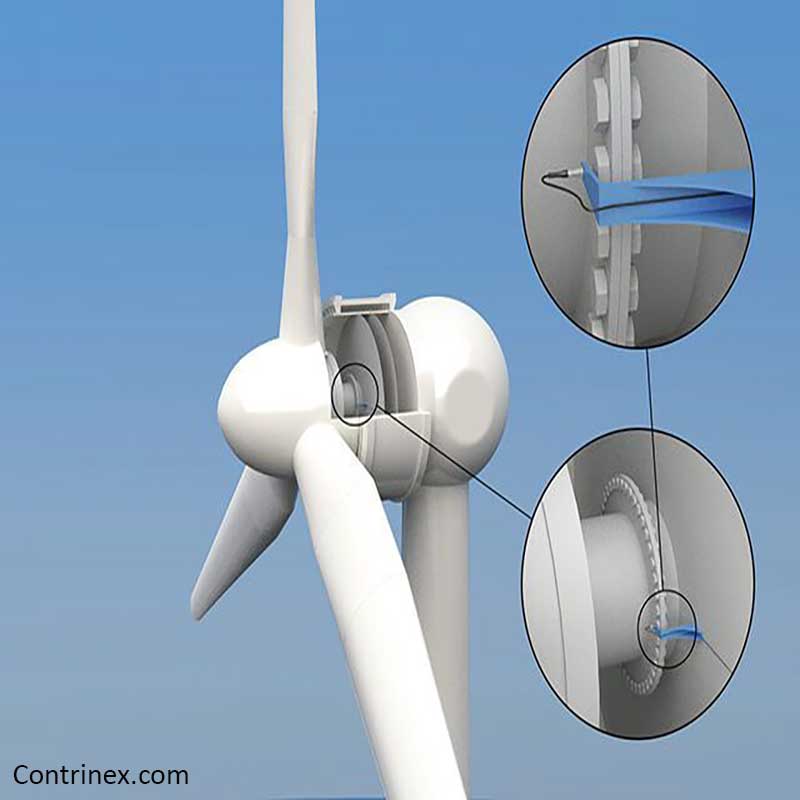

Measuring Rotation Velocity of Wind Turbine Blades by Rugged Inductive Sensors

So, we need special sensors.

Requirements of the sensors are:

• Simplicity

• Being non-contact

• High strength

What is the best solution?

Rugged inductive proximity sensor are suitable for this application.

The features of these sensors:

•IP68 or IP69K rated

•One-piece M18-diameter stainless-steel bodies

•A cost-effective alternative to traditional rotary-encoder technology

•High reliability

•High accuracy

•Particularly appropriate for the harsh •environment, on land and at sea

•Detection range: 10 mm

•Water-resistant

•Corrosion-resistant

The function of the sensor:

It detects the mounting bolts as they pass the sensing face and measures the speed of the blades.

The sensor's configuration:

The sensor is configured with an industry-standard PNP normally-open interface.

Connection to the control system:

The sensor is connected to the turbine's control systems through an integral M12 connector and PUR-sheathed cable. So, easy removal and replacement during routine maintenance will be possible.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do you like to know how these sensors work? Click on the following link to find out about proximity sensor working principles.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications.

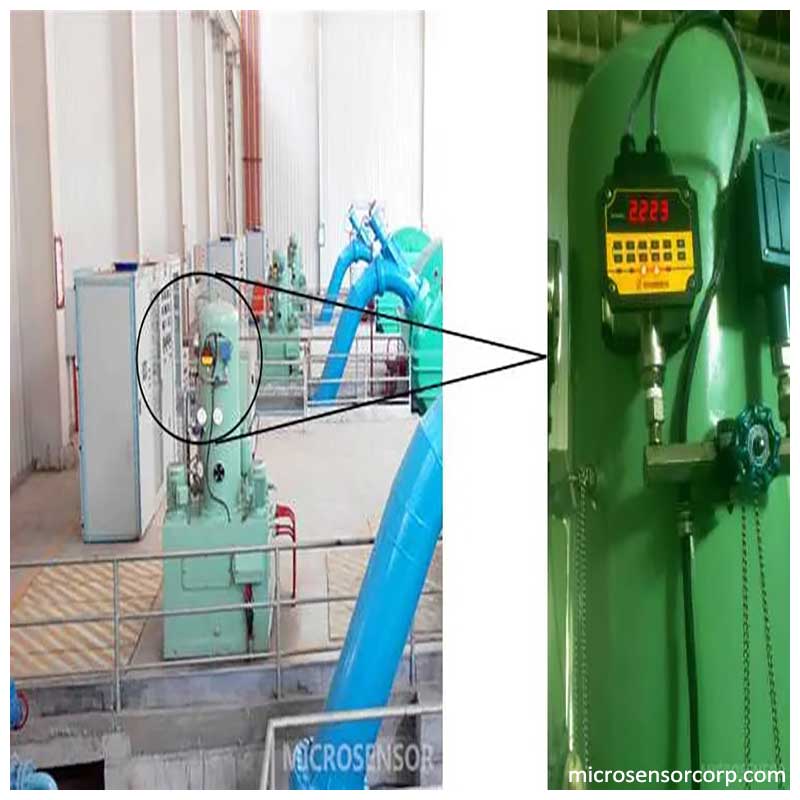

Special Pressure Transmitting Controllers for Hydropower Stations

Using Rapid Precise Sorting of Mixed-Metal Waste by Companies, due to Smart Inductive Sensors

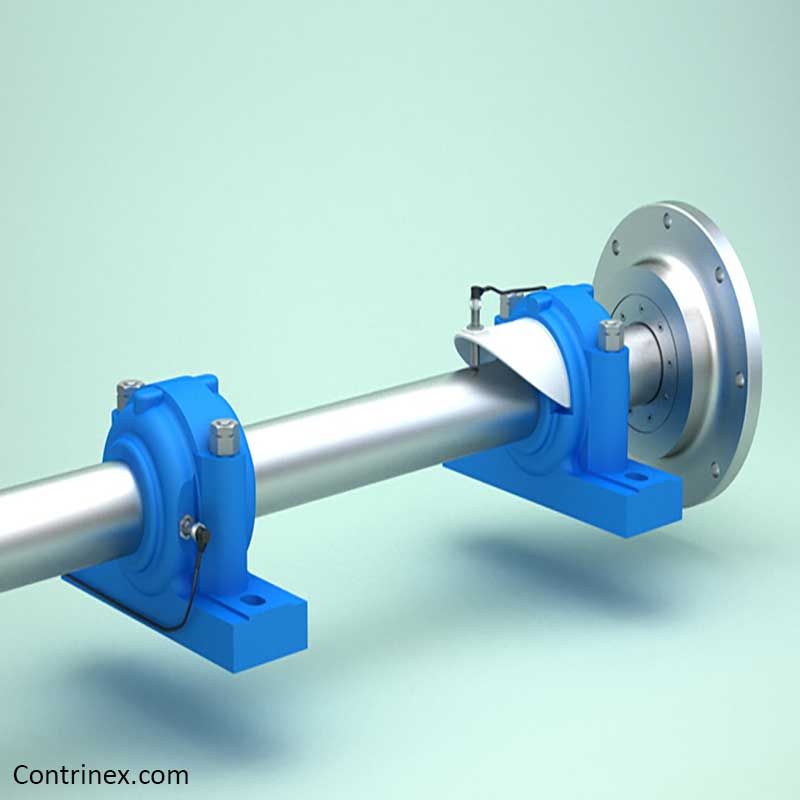

Affordable Condition-Based Monitoring in Rotating Equipment by Multi-Mode Intelligent Sensors

Related Products