Reliable Weld Immune Sensor in Automotive Welding Lines

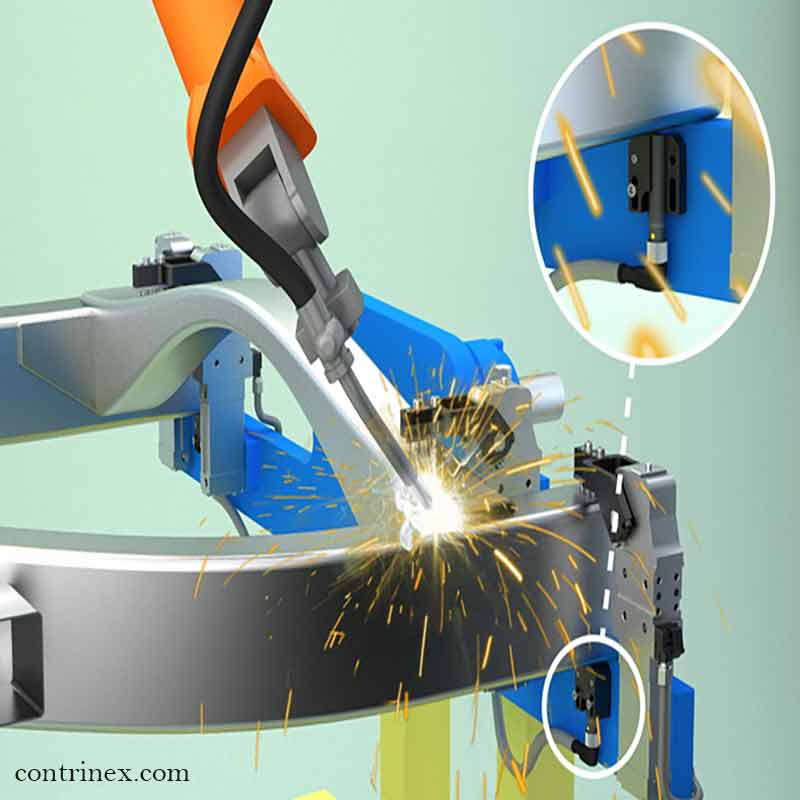

Failure to align two or more parts of an assembly in an automated chassis-welding line will result in an expensive piece of scrap. Sometimes it could even cause a damaged robot welding head.

Engineers need presence and position sensors that work with minimal maintenance. The welding spatter is a common challenge that causes rapid sensor degradation. In extreme cases, you should replace sensors that are not sufficiently protected daily. It is a costly and time-consuming activity.

Weld immune sensors to rescue

Sometimes sensors are directly exposed to weld spatter and strong electromagnetic fields. In this case, you can use weld-Immune inductive sensors. All external surfaces of these sensors are protected, preventing spatter accumulation. Also, optional spatter-resistant shrouding prevents cable damage.

Weld-Immune sensors combine the best detection sensitivity with immunity to electromagnetic interference. Robust metal-bodied construction also ensures excellent resistance to mechanical shocks and vibration. Additionally, some weld-immune proximity sensors aim at a technology named ACTIVSTONE®. It is a high-performance ceramic coating that is resistant to welding spatters.

ACTIVSTONE withstands frequent and aggressive cleaning regimes. It causes extending the service life of the sensor.

How IO-Link helps

These sensors provide an industry-standard interface to the machine control system through IO-Link. During initial calibration, each sensor’s configuration is stored on the local IO-Link Master. This allows plug-and-play replacement of sensors. This way there would be no loss of functionality and no need for recalibration.

The weld-Immune family is mounted close to the parts to be welded. Hence, they provide solutions for the toughest weld-related sensing problems.

Are you curious about these sensors? Learn more about it in our article Inductive Proximity Sensor Types.

Among the leading manufacturers of factory automation sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Identification of Switch Washers with Inductive Sensors during Their Production

Checking Complete Closure of Tools with Inductive Proximity Sensors

Checking the Engine Part Position during Manufacturing with Inductive Sensors

Related Products