RFID Tags: Appropriate Devices for Precise Detection of Position of Rail-Mounted Conveying Machines

Special devices are needed in manufacturing process of bulk material-handling equipment in order to sense the status of large rail-mounted reclamation-conveyors working in hot, dusty environments.

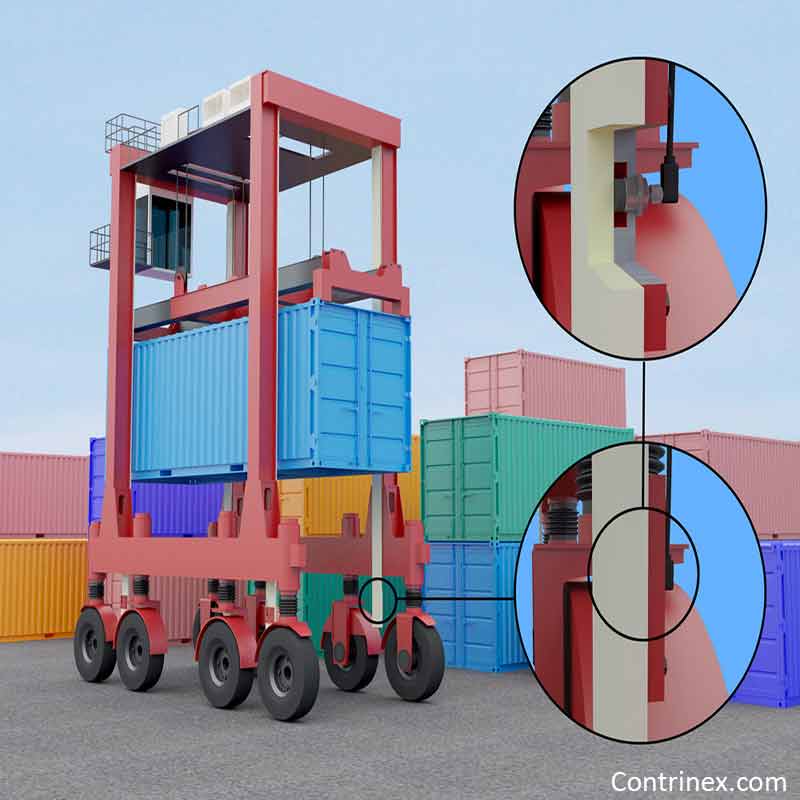

High-frequency RFID read/write modules and 30mm-diameter RFID transponder tags are designed for this application. Rated up to IP67, the M30-diameter RW modules have PBTP detection faces and V2A stainless-steel housings, making them appropriate for the requirements of the environment.

The ConIdent® passive transponders don't need any inner energy supply and, with PBTP synthetic housings, have the same IP67 rating. The selected combination provides RW distances of up to 45mm, best for the required working conditions.

As the system passes a tag, the RW module reads its identification number at high speed; this is transmitted through a PROFIBUS DP interface to the client’s managing system. Operation is unbiased of the path of travel.

ConIdent® RFID tools can detect the status of a machine accurately and reliably and the long detection distance inhibits any hazard of collision harm. Furthermore, high service life and robustness not available from other status-sensing systems are provided for the clients.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Assessing Wear in Plain Bearings via Rugged Inductive Sensors

Figuring out Multiple Components throughout the Process of Testing Pressure-Hose

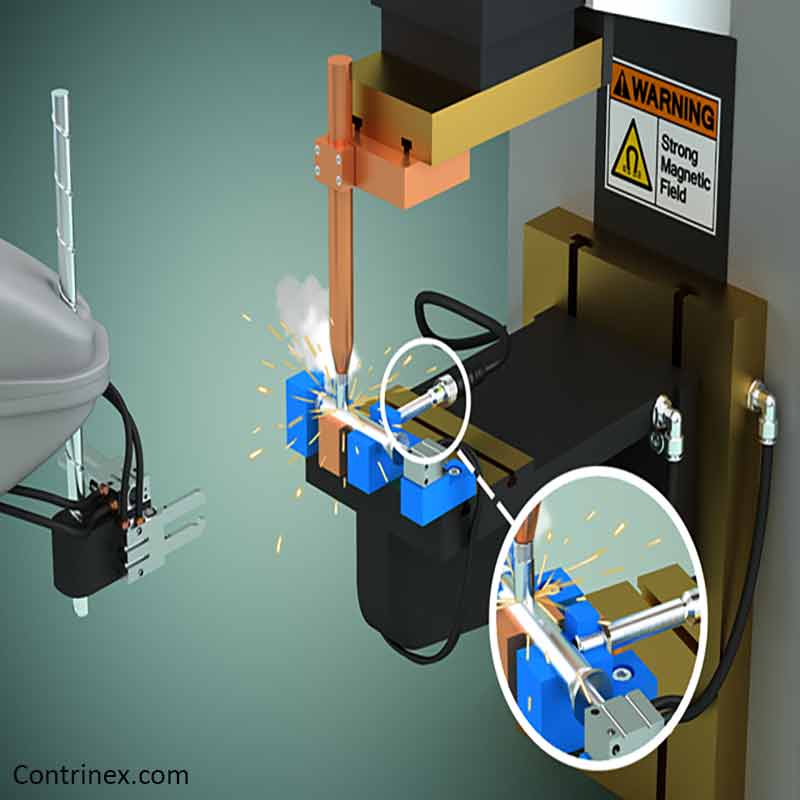

Providing Significant Preservation with Minimum Cost in MF Resistance Welding of Aluminum Assemblies by Factor 1 Weld-Immune Sensors