Rugged Inductive Sensors for Preventing Overloading Of Hook Lift Truck Arm

Hooklift systems generally work in a semi-automatic manner. Before the start of the lifting sequence by a hook lift truck, a reliable sensor must be present. This sensor is needed to detect the position of the arm. This position assures that the arm is not extended. These sensors are also subject to mechanical shock and vibration. They must be vigorous and tolerate water, mud, dirt, and ice.

Rugged inductive sensors are the solution.

Features:

• IP68/IP69K rated

• one-piece AISI 303 (V2A) stainless-steel construction

• suitable for the harsh conditions due to their vacuum-encapsulated electronics

• easy removal and replacement due to a proper connection to the control system

• resistance to shock and vibration

• resistance to corrosion, water, mud, ice, and salt

• high reliability

• cost-effectiveness

How the sensor works:

Before the lifting sequence starts, the hydraulic hook lift system retracts the telescopic arm. The sensor is set up in the housing of the extending part. It detects the position of the arm when it is retracted. There is no risk of accidental collision between nearby moving parts.

Getting the arm positioned in the right way enables the mechanism of lifting.

Here you can view a huge selection of inductive sensors.

Want to know more about these sensors? Check out our article to learn about Inductive Proximity Sensor Types.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

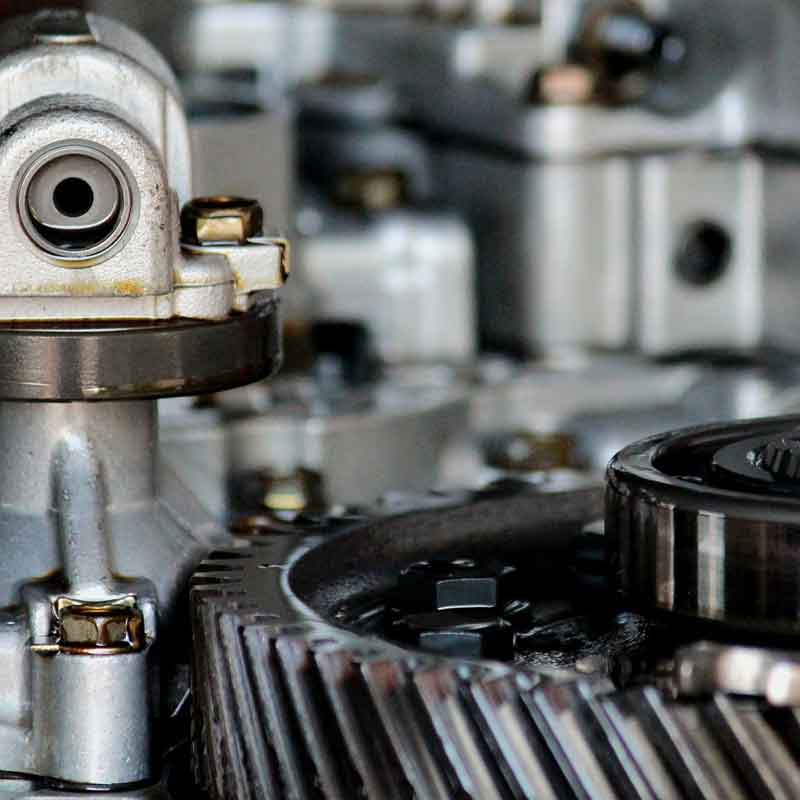

Detecting Height to Check Gear Assembly Versions in the Manufacturing Process

Figuring the model of vehicles out by detecting the type of chassis

Blind Sensing Used in Made-to-Measure Fixtures

Related Products