Selected Applications From Food and Beverage Industry

An innovative way to transmit I/O signals in conveyor lines which ensures more resistance to noises and easier wiring is to use Remote I/O boxes.

Temperature/humidity controllers can help us in controlling and maintaining proper temperature and humidity for dough fermentation in baking machines.

After the production of goods is done and when the goods are transmitted to containers in packaging lines, the number of items in each container must be taken under control. So, the containers must be equipped with sensors that can detect that number. Vision sensors have proved to be the right solution.

Hybrid recorders are devices applied in industrial refrigerators for recording temperature data.

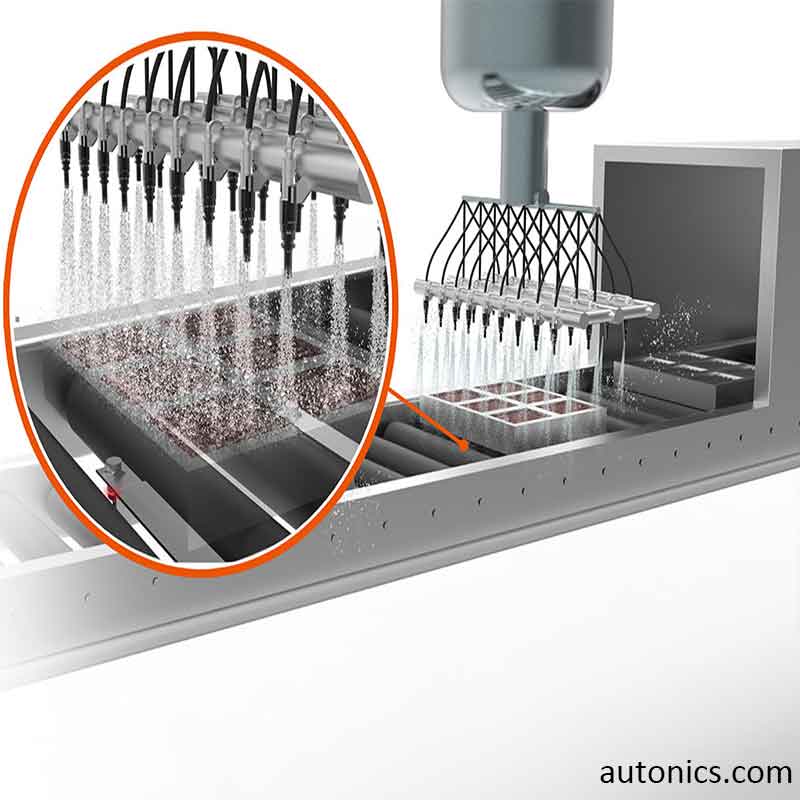

In the food industry, raw vegetables such as potatoes are washed on washing conveyors by high-pressure water sprays. One of the important factors in guaranteeing washing reliability is the optimum pressure of water sprays. Digital pressure sensors are the right choice for measuring the pressure of water sprays.

During meat processing, pieces of meat are put on food trays and Spices and other additives are added to them. Detecting the location of food trays is a critical matter that can be done using Full-metal inductive proximity sensors.

In the food industry, food containers placed on conveyor belts should be sealed properly. The status of Sealing in those containers can be reliably detected via Vision sensors.

We can assure whether expiration date printing is present on packages of food goods or not using Vision sensors.

Food display refrigerators have been welcomed by customers in stores and even homes for several years. Maintaining the temperature of these refrigerators in the optimal range is a critical matter which can be aided by Refrigeration temperature controllers.

Nowadays, food storage refrigerators are widely used in the food industry. Refrigeration temperature controllers can be applied for controlling the temperature of these refrigerators.

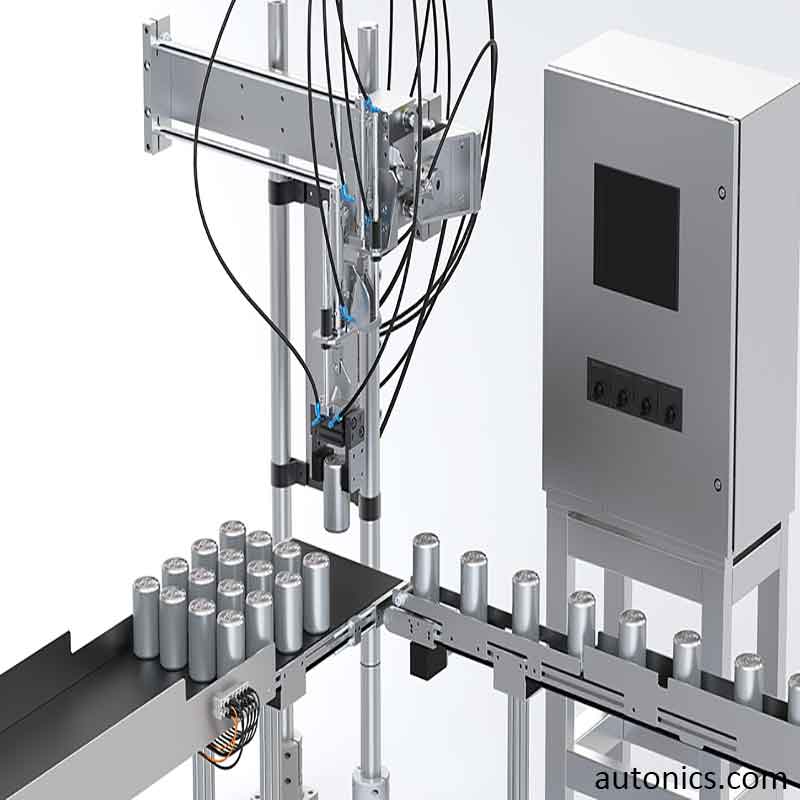

Detecting the presence and number of bottles in the process of beverage packaging can be detected via Proximity sensors.

Aluminum cans used in beverage packaging lines can be detected via Front/side mounting photoelectric sensors.

The temperature of beverage storage tanks must be in the optimal range. That's why it is continuously checked and monitored. 2-Channel USB temperature data loggers transmit temperature data of beverage storage tanks to data processing centers (PCs).

The temperature of commercial coffee roasters needs to be continuously checked. LCD display temperature controllers perform this important task.

Controlling the temperature of industrial food agitators is an important task that can be performed via Dual-speed PID temperature controllers.

Time controlling in frying machines can be reliably performed using Analog twin timers.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Semiconductor/Display Applications

Miniature photoelectric sensors figure out status of cartons in process of packaging

Extra Distance Inductive Sensors figure out Aluminum capping of Food Containers