Selected Applications From Logistics Industry

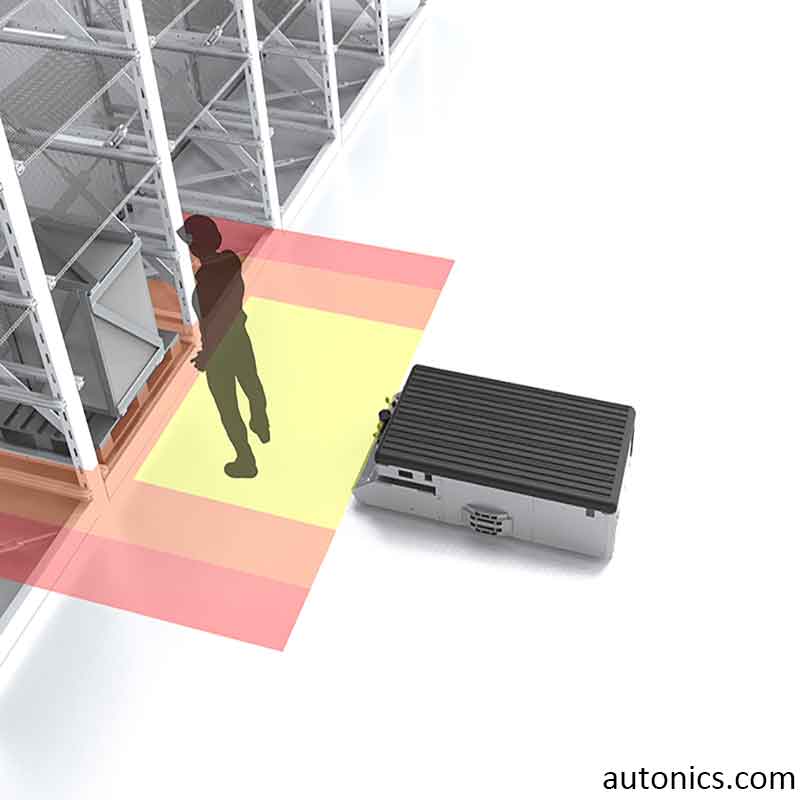

It is necessary to inhibit collision with personnel and objects when Autonomous Mobile Robots and Automated Guided Vehicles work. Laser scanners aid us in this area.

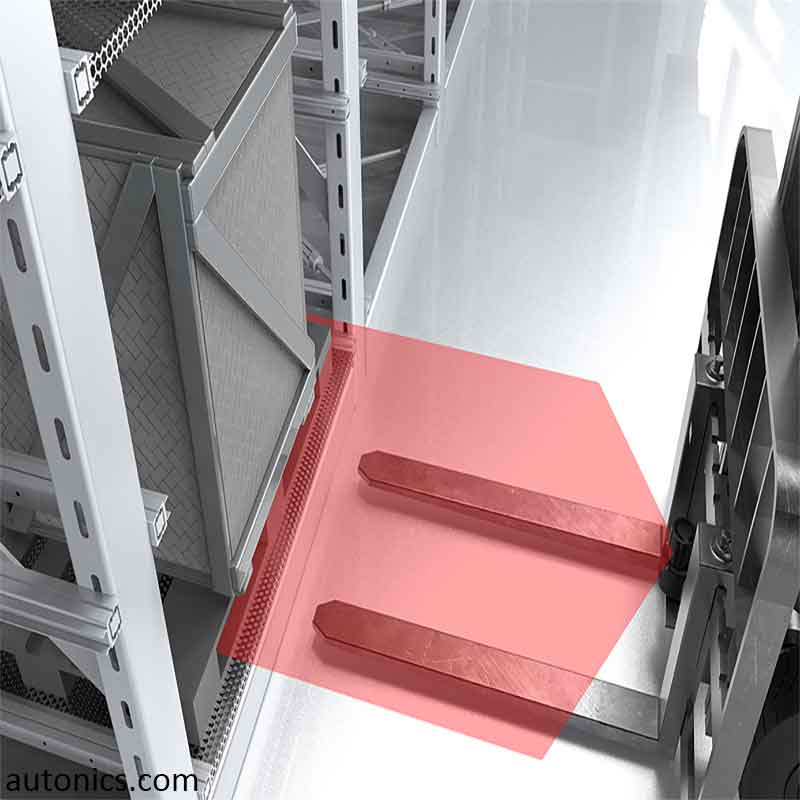

In the logistics industry, we must be able to detect the size of the pallets and also detect the occupancy status of the trays for pick-up. Laser scanners help us in this matter.

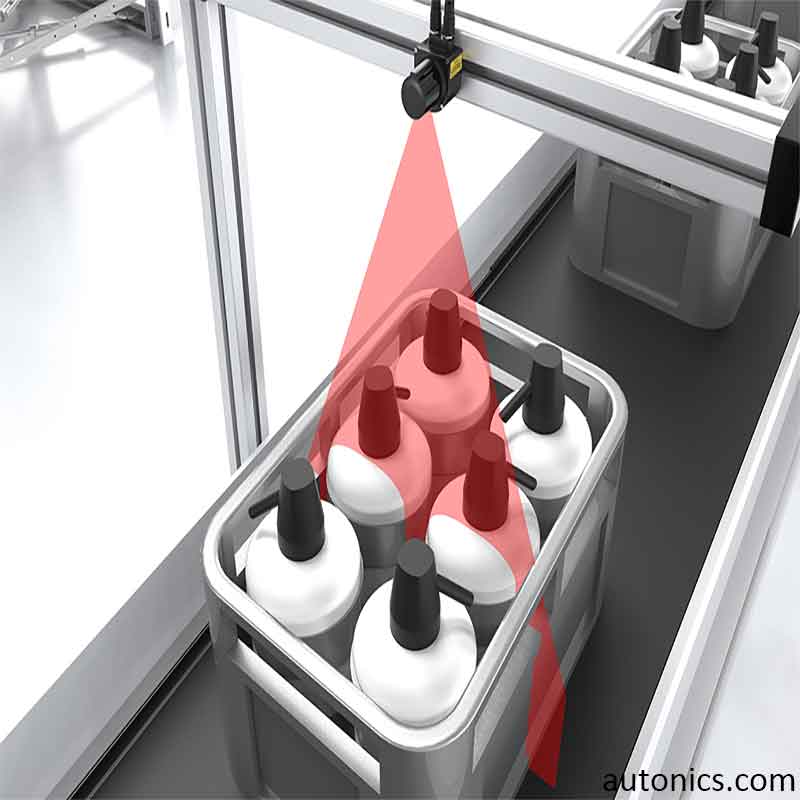

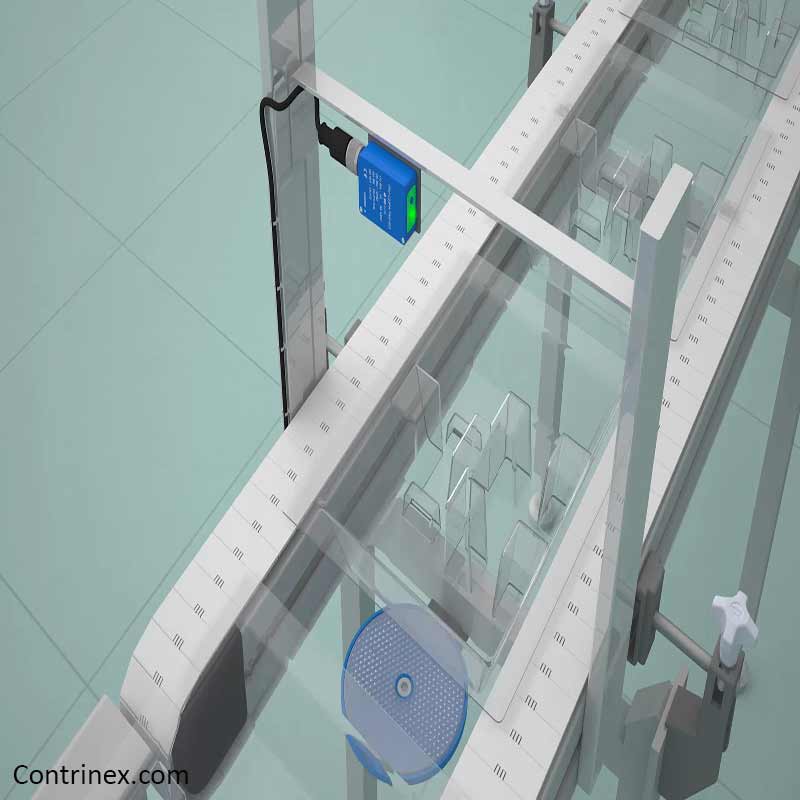

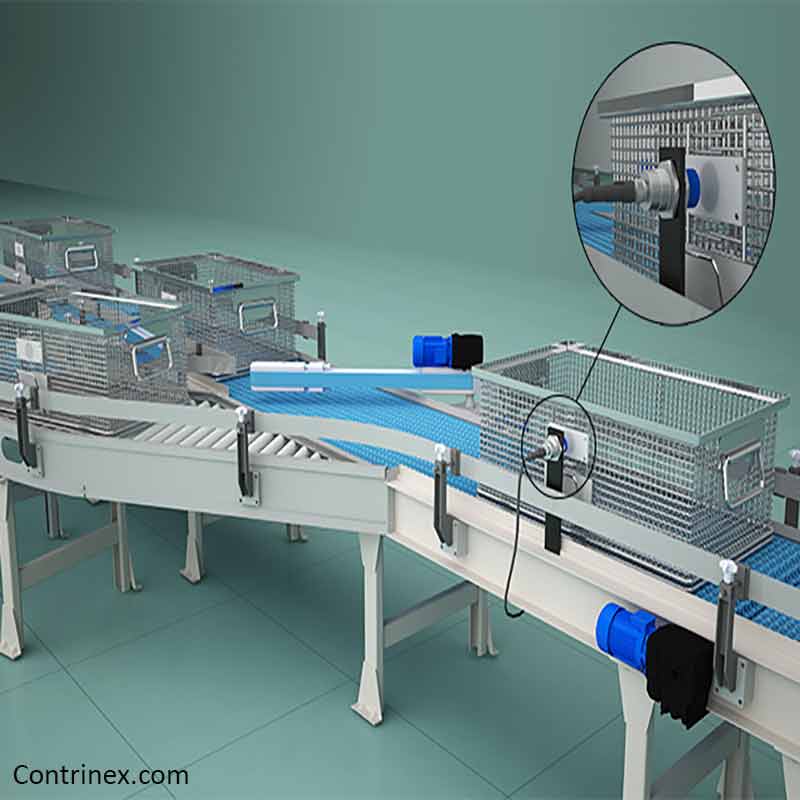

The inner status of tote boxes conveyed through conveyor belts should be continuously monitored. Laser scanners can be the proper solution to help us in this matter.

Detecting the entry/exit of automobiles in warehouses using Laser scanners set up on the doors.

City toll gates on roads are kiosks where vehicles stop for a few minutes and then pass. By equipping these gates with laser scanners, it is possible to detect the passage of vehicles automatically and intelligently.

Laser scanners can be applied at retail stores for security and monitoring purposes.

Displaying different various data including current, voltage, and power factors in the factory and building distribution boards can be well assisted by Digital panel meters.

Graphic panels that can be set up on robots and automated guided vehicles (AGV) can reliably monitor and control automatic movement.

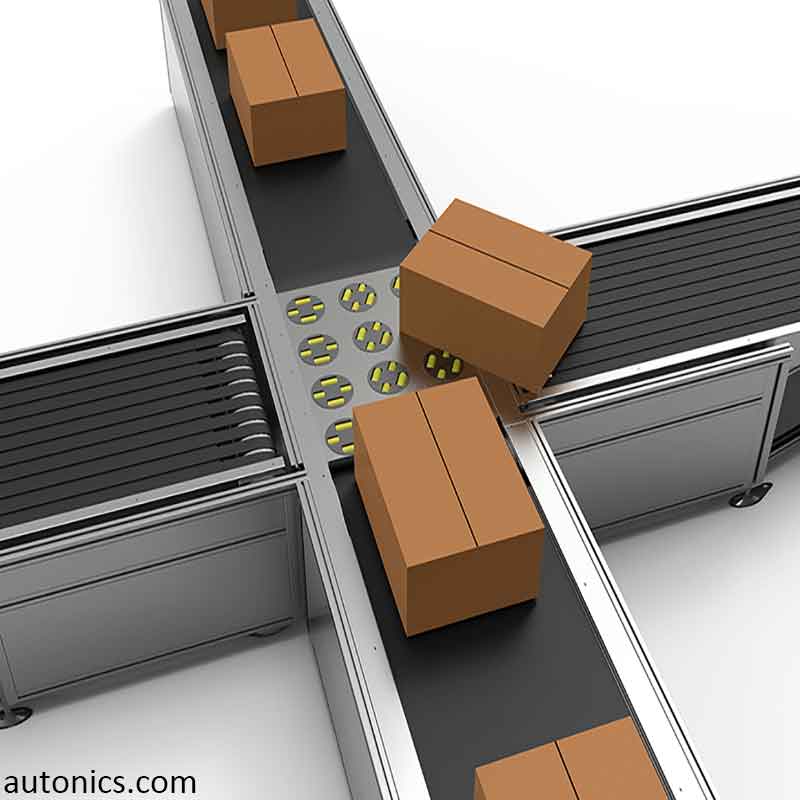

The Closed-loop stepper motor system can be reliably used in the automatic sorting of merchandise to appropriate destinations.

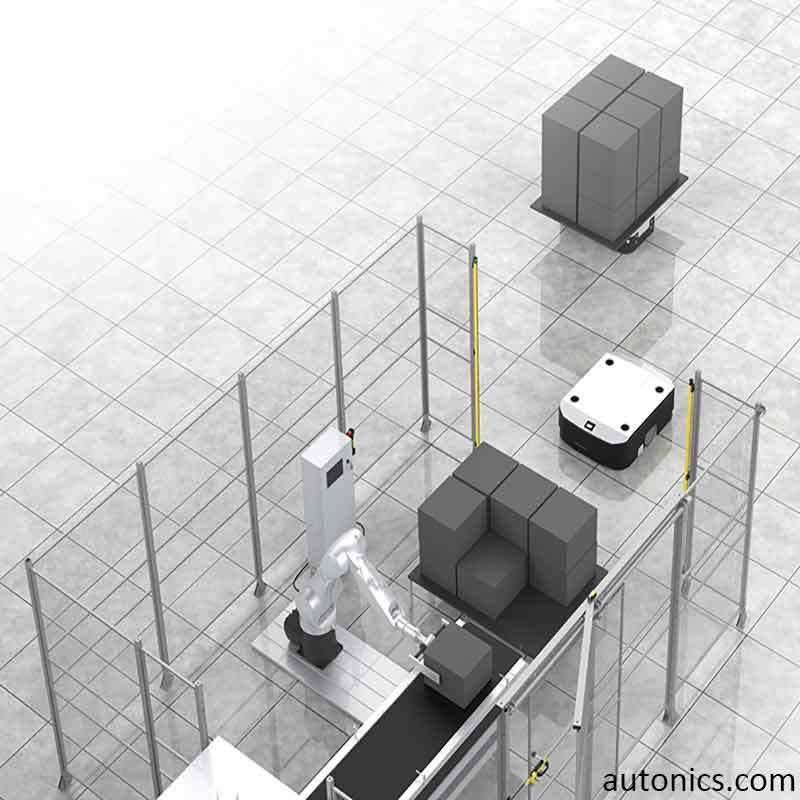

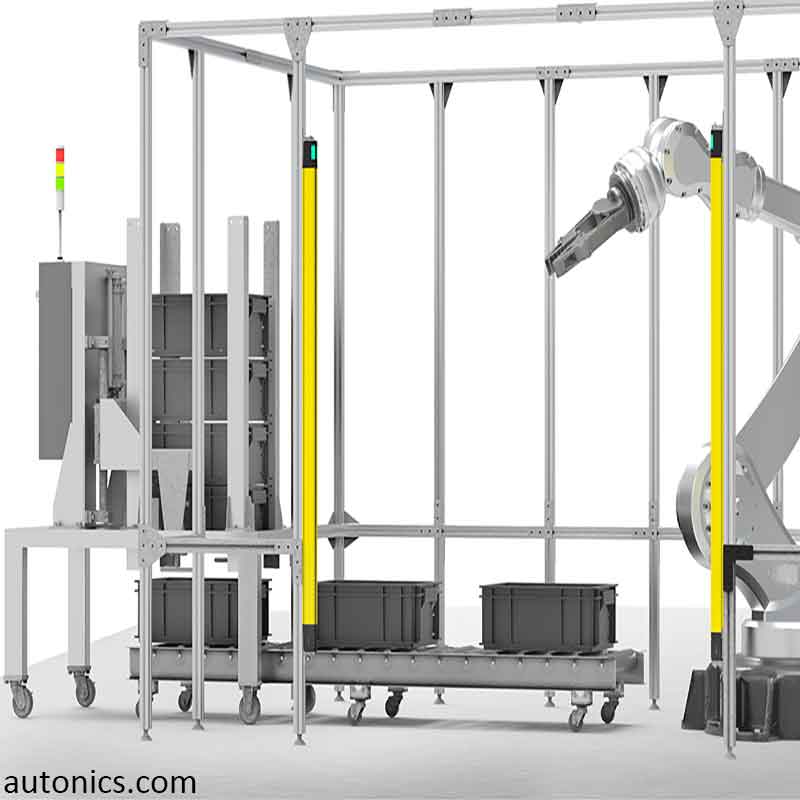

Of course, if people, including employees, enter robot operating danger zones, they will not only interfere with the operation of the robots but there is also the possibility of safety problems. Therefore, we need tools that, in the event of such an incident, firstly detect it immediately and secondly, stop the operation. In this regard, we can be assisted by Safety light curtains that provide us with both of these facilities.

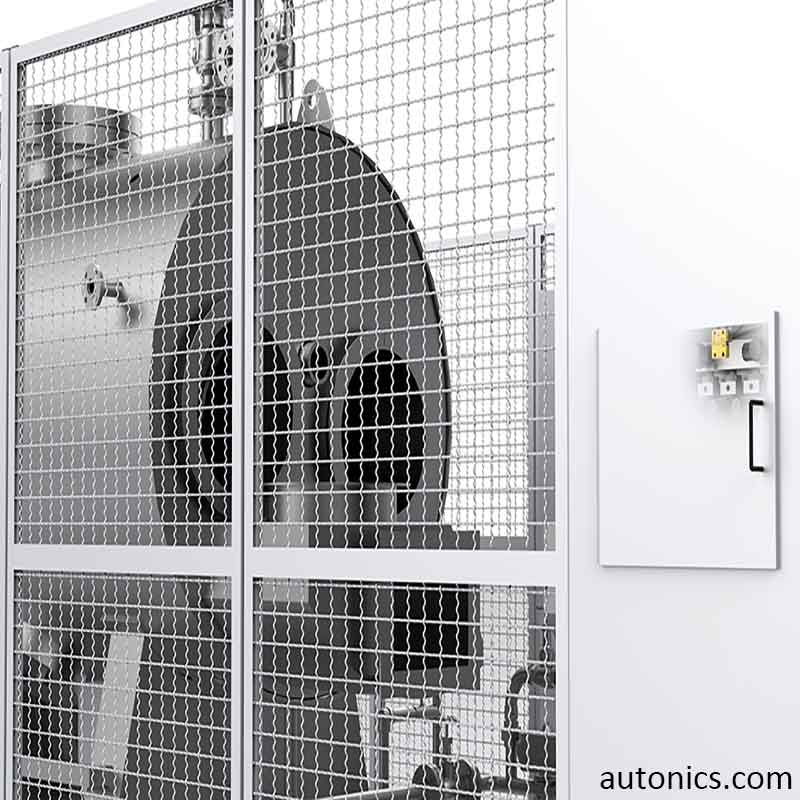

Magnetic non-contact switches aid us in detecting the safety doors being opened or closed in the distribution board.

Pressure changes in vacuum grippers in the process of transportation can be detected via compact size pressure sensors and Multi-channel pressure sensor indicators.

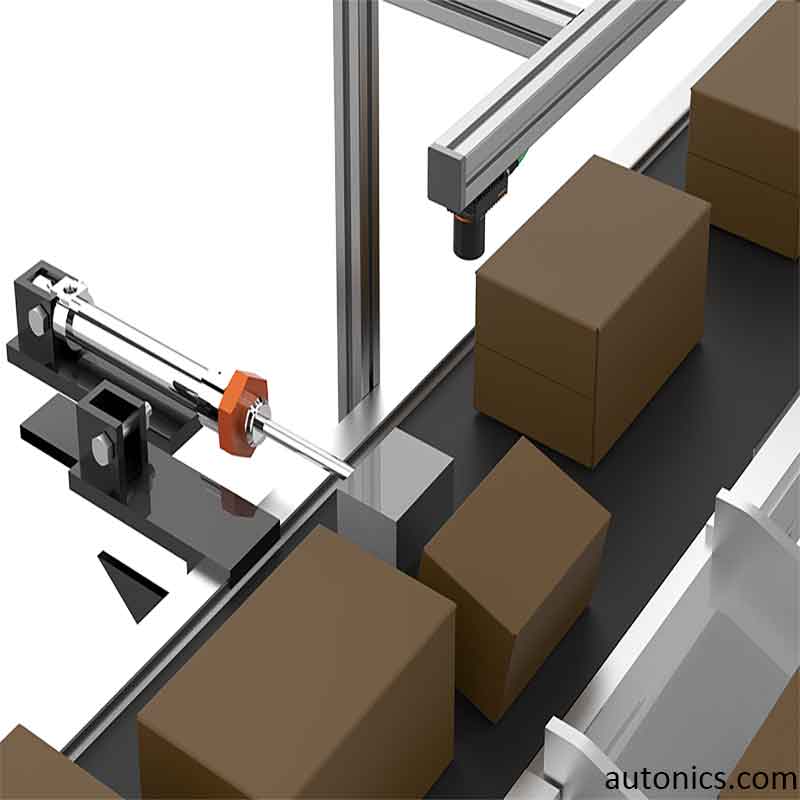

During the process of goods shipping, boxes of various sizes can be transmitted via conveyor belts. The size of those boxes is a critical parameter that can be identified by Vision sensors.

Color mark sensors immediately identify the inconsistency or the wrong color of the boxes placed in the packaging process.

Various objects and goods are brought into or out of warehouses on trays. This entry and exit can be detected with the help of Front/side mounting photoelectric sensors.

Positioning control of hoists can be reliably performed via Rotary encoders.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Machine Tools Applications

New UV technology helps with detection of clear packaged products

Read-Write Modules with IO-Link Connectivity make Process Control simple