Selected Applications From Machine Tools Industry

The temperature of reflow ovens should be precisely under control. SPR3 series single-phase power controllers are used in reflow ovens for this purpose. They do their tasks using feedback control.

The quantity and cutting length of materials must be controlled in the process of production. Counter/timers have proved to reliably do this job.

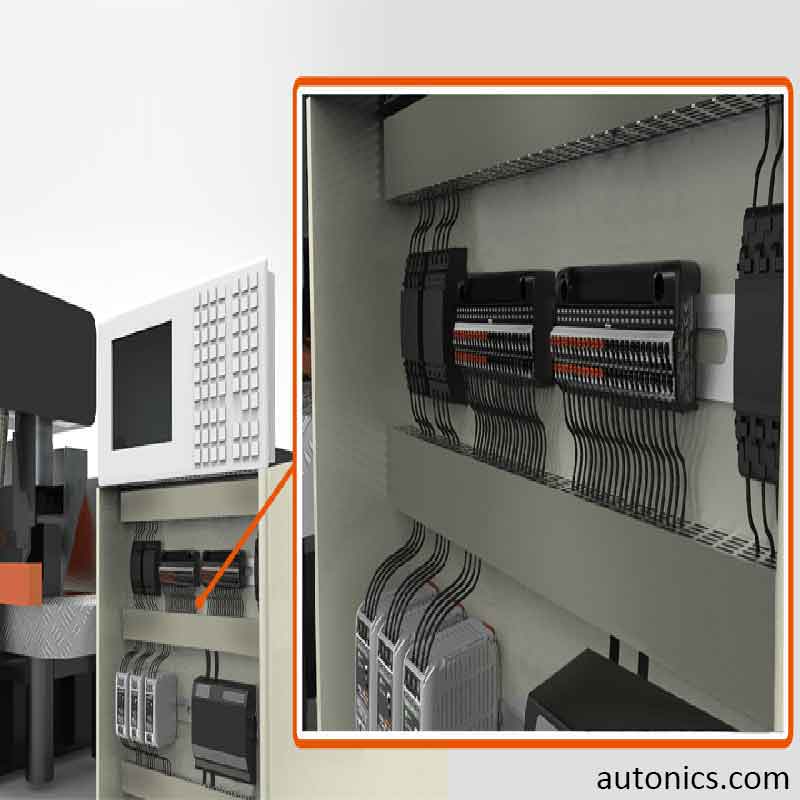

The task of distributing power supply from switching mode power supplies (SMPS) in machining centers can be performed reliably by terminal blocks.

Raw material heating occurs during the process of extrusion molding and its heat levels can be reliably controlled via Temperature controllers.

The thickness of steel plates can be precisely measured by Displacement sensors.

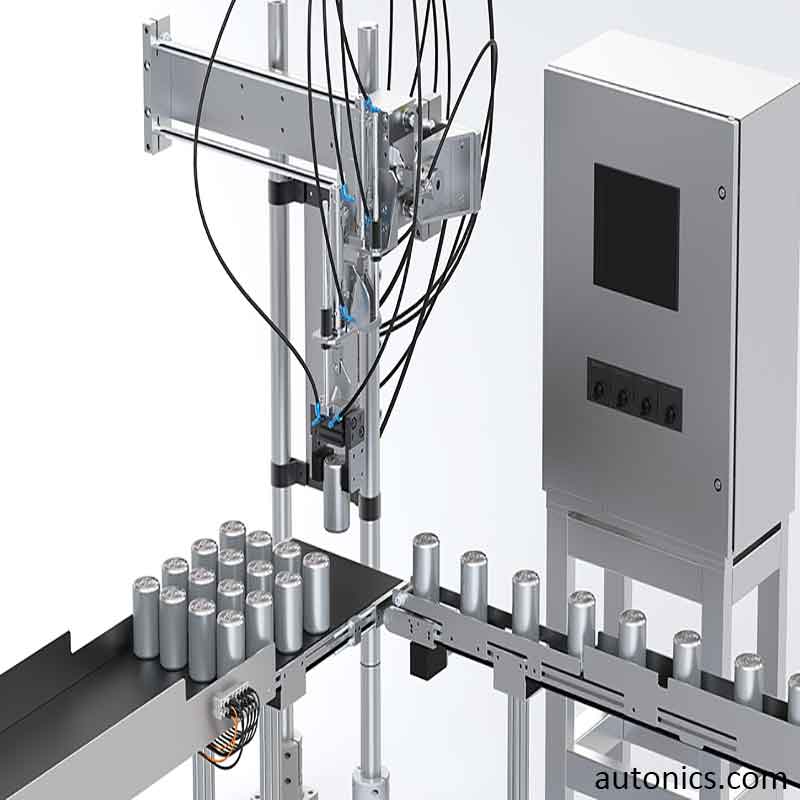

Controlling moving PCB boards into conveyors in PCB loaders can be accurately done via the closed loop stepper motor system.

Controlling the distance on conveyor belts in SMT machinery can also be done via the closed loop stepper motor system.

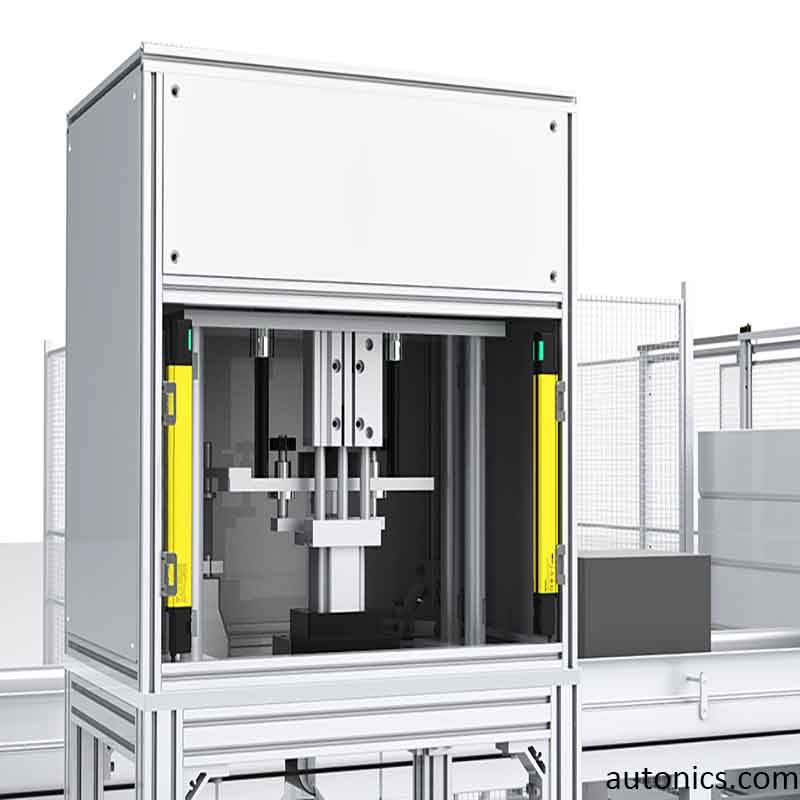

If a part of the operators' bodies or hands gets inside the press machinery while working, it is necessary to stop the machinery immediately. Safety light curtains are responsible for identifying the physical obstacles in press machinery and stopping the machinery from working.

In the machine tools industry, the heat levels of heating and melting raw materials should be controlled. Temperature controllers are the proper solution for this matter.

I/O signals in machine tools can be transmitted via Remote I/O boxes.

BJR series oil-proof/oil-resistant photoelectric sensors can be introduced as advantageous tools applied in the process of CNC hole drilling.

The task of controlling X-Y axis shafts in compact-sized milling machines in the machine tools industry can be reliably and accurately done via stepper motors and Photomicro sensors.

Temperature controllers and other control devices inside machining centers can be easily and well connected via Relay terminal blocks.

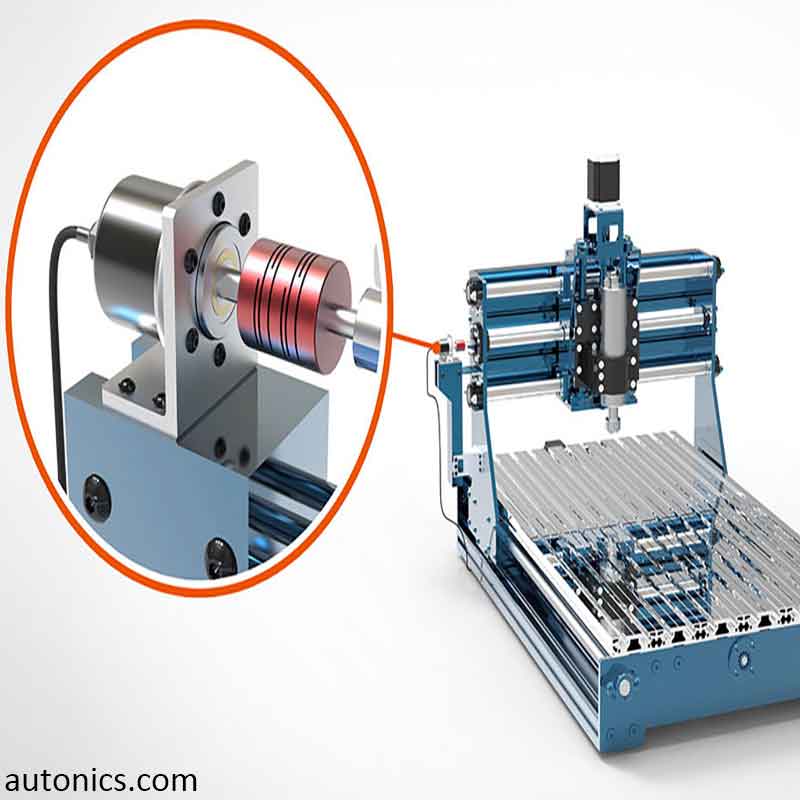

The rotation of shafts on compact-sized milling machines can be well detected and hence controlled via Rotary encoders and couplings.

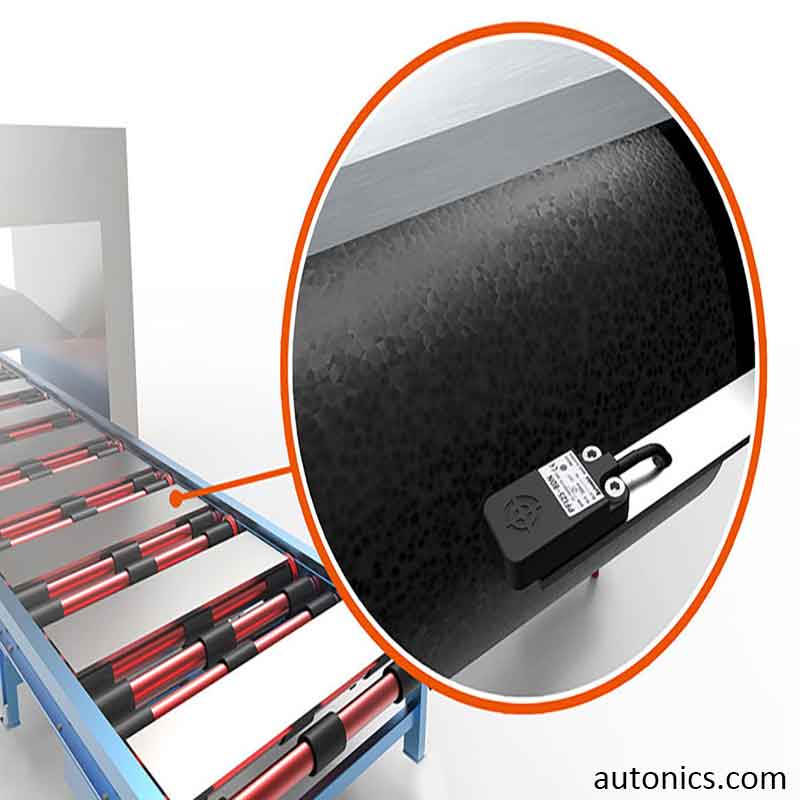

The issue of whether metal plates in metal processing and production lines are present or not can be well detected via Flat type proximity sensors.

Controlling the temperature of heating tools in reflow machines is a critical matter which can be done through Single-phase integrated solid state relays.

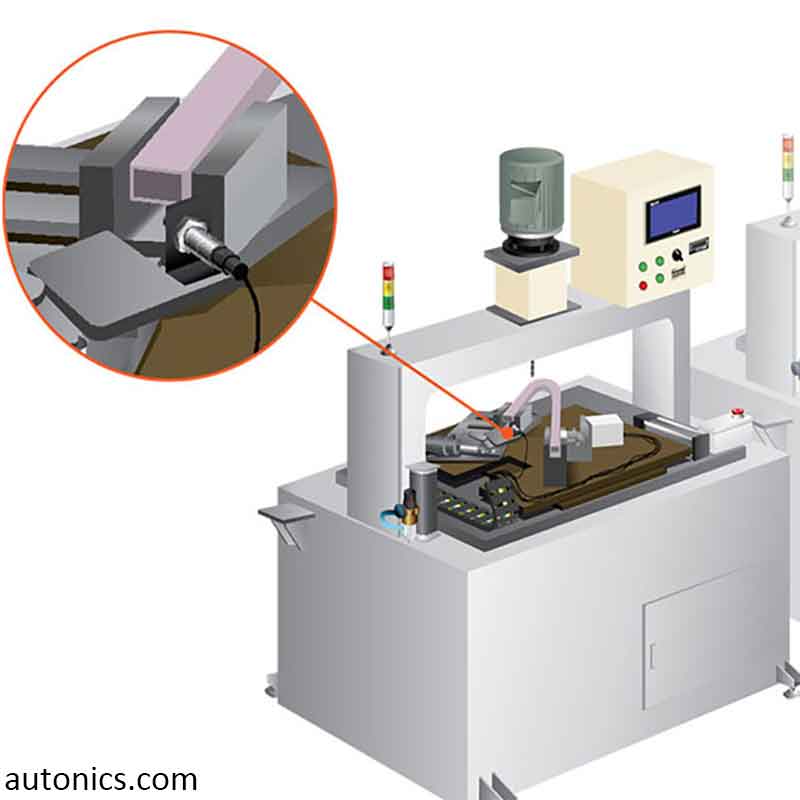

We can introduce Proximity sensors as limit switches which can check the accurate location of different components in automatic drilling machines.

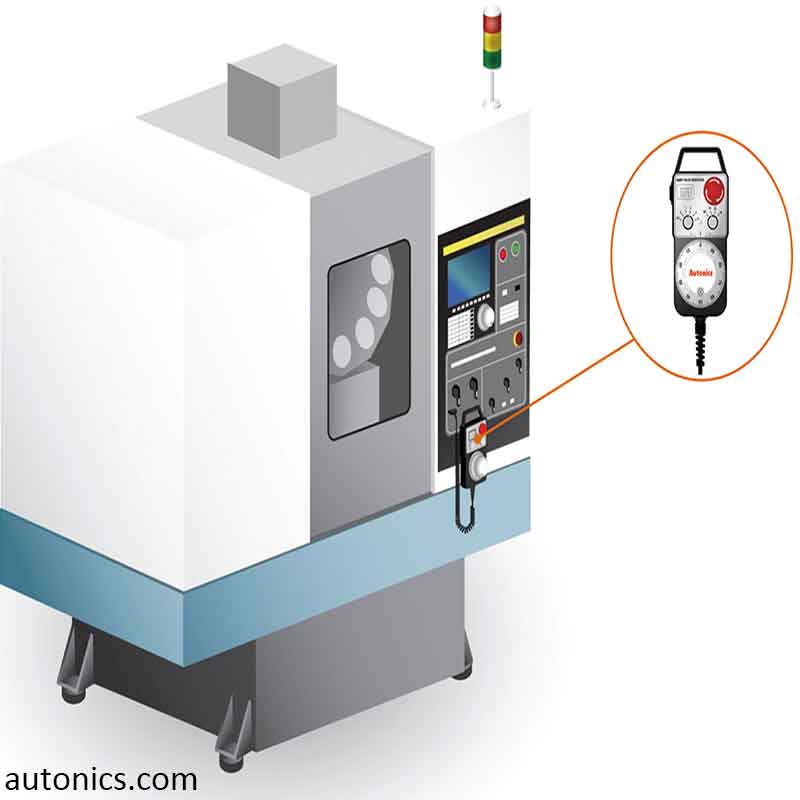

The location of tool components in machining centers should be taken under control. This can be performed via Handwheel type rotary encoders.

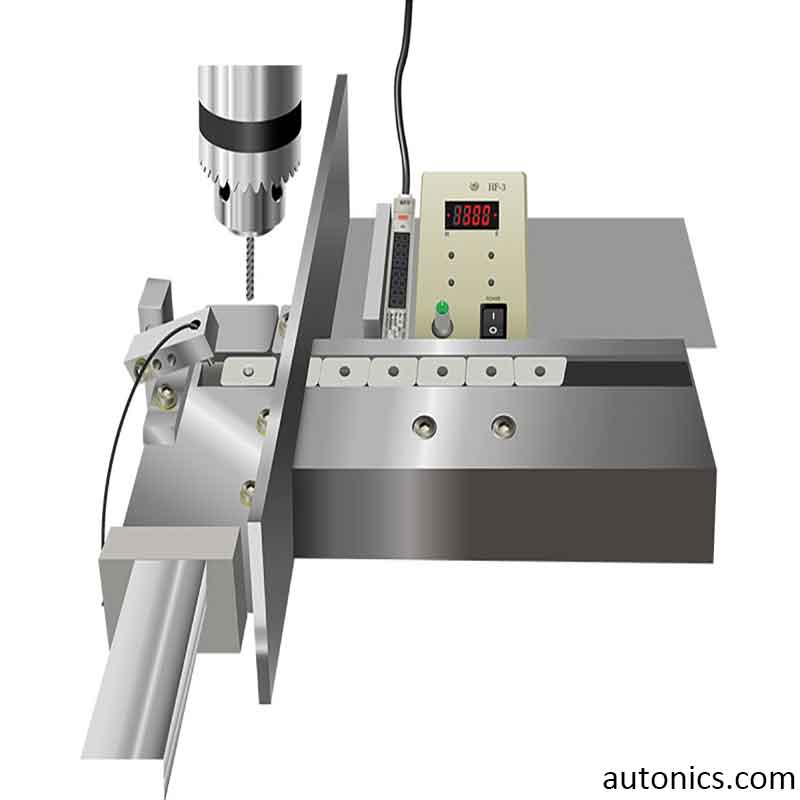

A reliable way for measuring the cutting lengths in pipe cutting machines is to use Wire-type linear scale absolute encoders.

Screwless type interface terminal blocks are dependable tools designed for connecting and wiring switching mode power supplies and other controllers in CNC machining centers in a simple way.

Fiber optic sensors, Graphic panels, and proximity sensors can be applied to hole drilling machines.

An important issue that needs to be considered In the process of glass production is detecting glass panels. Compact, high-performance photoelectric sensors help us to gain this objective.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Circuit Board figuring out for Controlling of Reflow Soldering Process

Semiconductor/Display Applications

Other Food and Beverage Applications