Sensors for Detecting Double-Sheets for Deep-Drawing Presses

In the automotive industry, special presses produce profiles from Metal sheets. During deep drawing, these sheets should be lubricated to cut friction. But sometimes, the oil causes two sheets to stick together and form a double sheet. Such double sheets can harm forming tools.

Former alternative sensors were tough to set up, and most of them couldn't detect overlapping sheets reliably.

What is the solution?

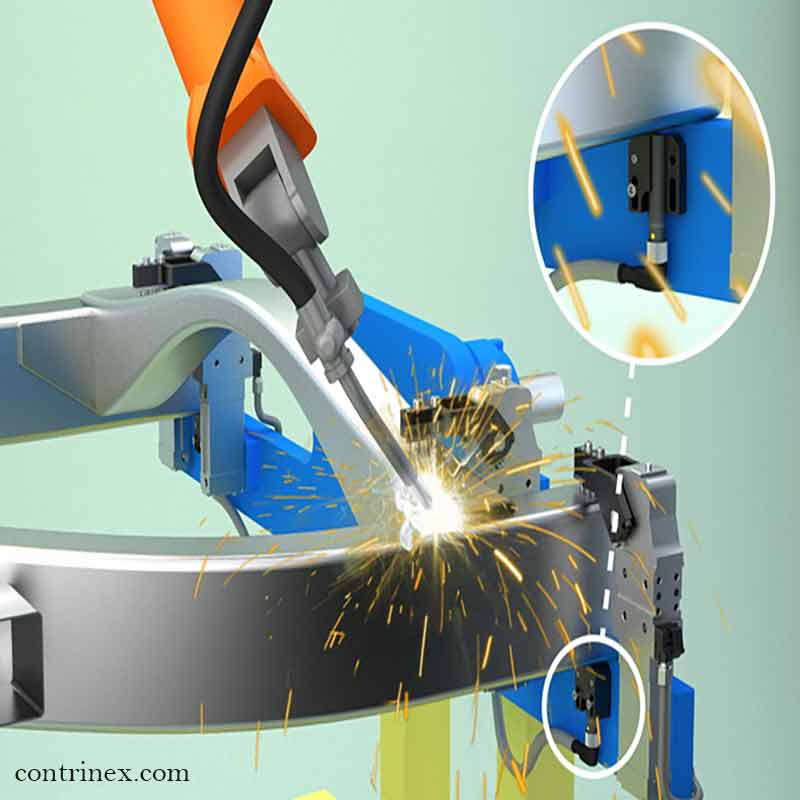

A rugged metal sensor is required to detect the presence of overlapping sheets. Such a sensor must also be able to stop the operating cycle if those sheets are detected.

Features of the solution:

• Condet® technology ensures that sensing happens independently of the target material.

• Highly vigorous due to the One-piece stainless steel material

• Compact size

• A threaded housing with an ideal diameter

• An optimal detection distance lowers the possibility of mechanical harm by minimizing direct contact with the target

The function of the solution:

Since the sensor is set up for the thickness and material type of sheets, its function is easy. It starts when an overlapping sheet is found. An industry-standard PNP connects straightly to the customers' control system by a normally open configuration.

Click on inductive sensors if you want to investigate more about the solution.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

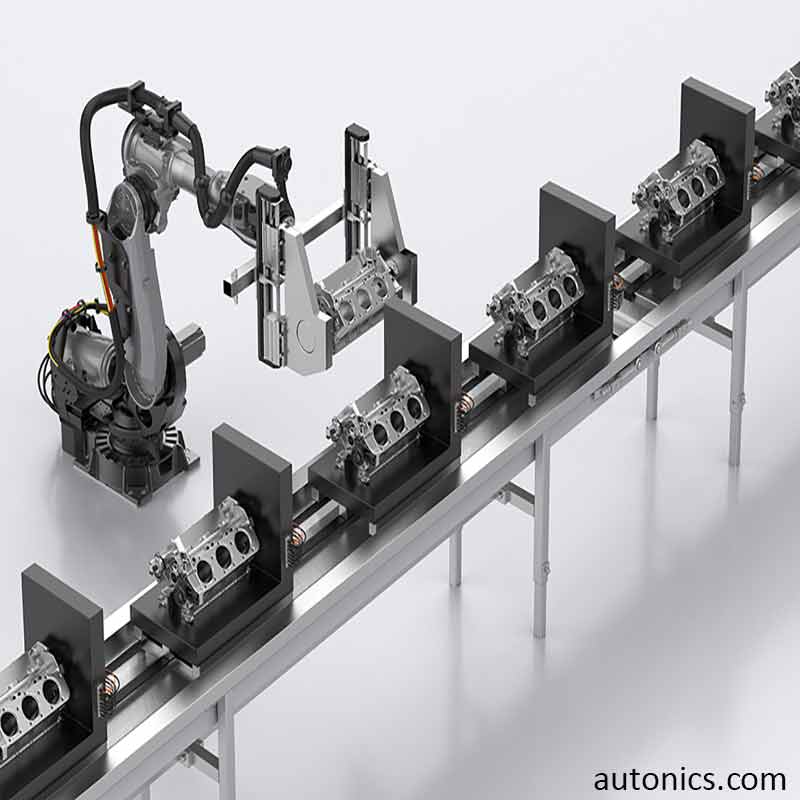

Radio Frequency Identification (RFID) for components in Optimized Process Control

Manufacturing Automobile Components

Reliable weld immune sensor in automotive welding lines