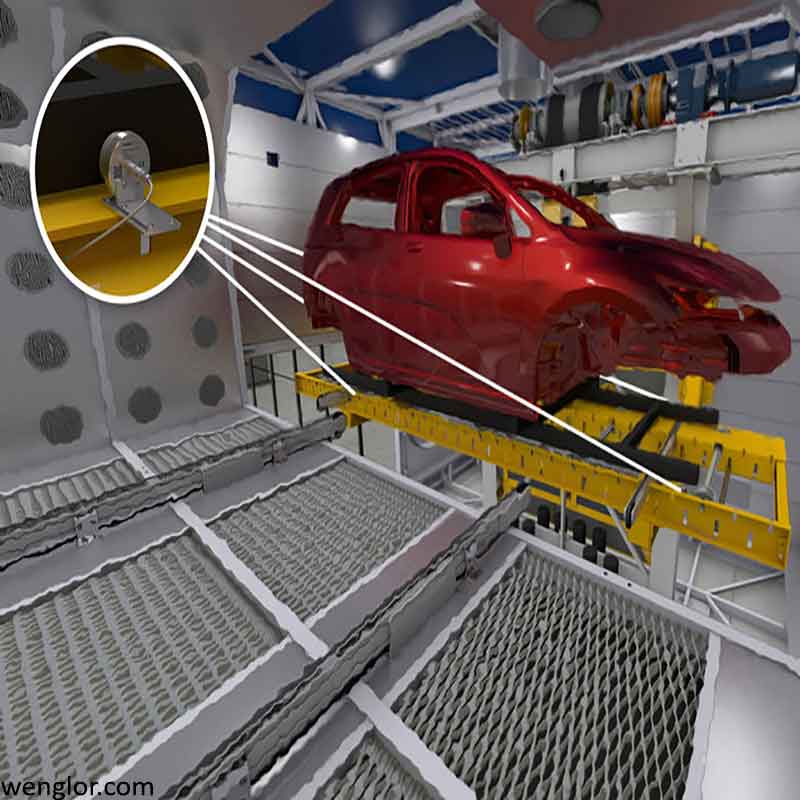

Special Inductive Sensors for Figuring out the Position of Skids in Automotive Painting Industry

One of the mandatory steps after painting the car body is to dry the car body shells in drying ovens under high temperatures. Craftsmen must ensure the correct position of the skid beams along the conveyor belt and consequently continuous transport.

Inductive sensors for extreme temperature ranges are designed to detect the position of the skid beams. These sensors are installed next to the skid lifting device and detect metal objects at high temperatures without direct contact and are highly durable thanks to having high switching distances and their vigorous construction.

They have a vigorous and flexible cable. So, the regular lifting and lowering movements of the skids don't have adverse effects on the measurements.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Special Data Loggers for Open-Pit Mines

Flow Measurement in Metallurgy Industry: Orifice Flowmeters

Detecting the Position of Skid Carriers in Automotive Industry via Inductive High-Temperature Sensors

Related Products