Supplying Stroke Feedback in Pressure Intensifier of Water Jet Cutting Machines via Inductive Sensors

Water jet cutting is used in many industries to create accurate and complicated cuts. High pressure water is created by a pressure intensifier.

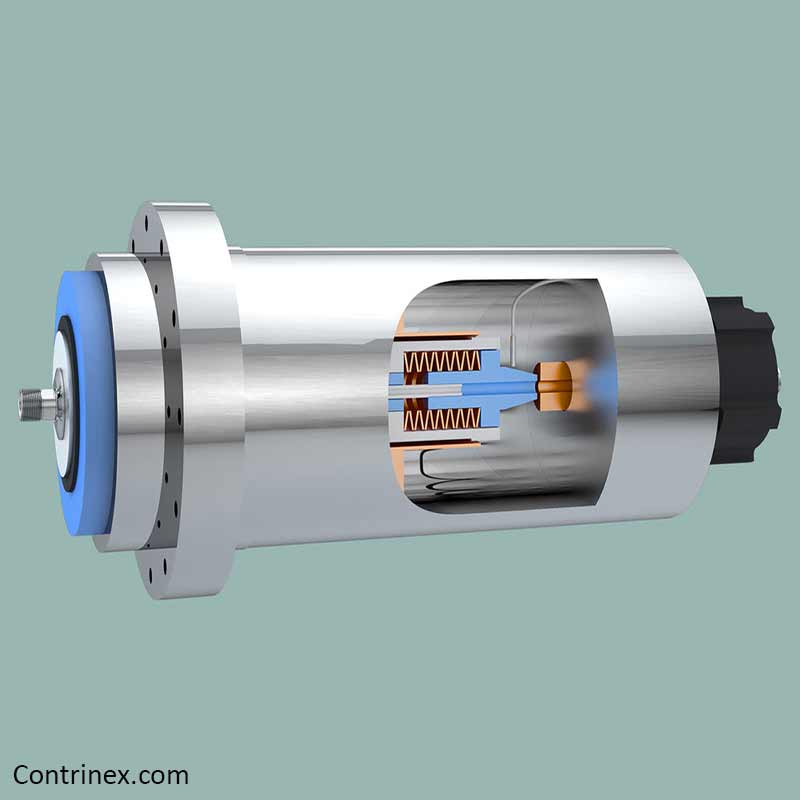

These intensifiers are systems of counter-moving hydraulic pistons that drive small cylinders.

A directional control valve regulates the reciprocal action of these opposing pistons.

In this high-pressure hydraulic system, there must be a reliable way to provide accurate stroke feedback to the directional control valve.

High-pressure inductive sensors seem to be the right instrument to do that.

Some features of these sensors:

• Resistant to pressures up to 500 bar

• Resistant to temperatures up to 100°C

• Sensing distance: up to 3 mm

• Long-term reliability

• Protected against moving parts

• Maximum rating: 1000 bar

Where are these sensors mounted?

Two high-pressure inductive sensors are mounted in the hydraulic piston chamber.

How do they work?

A signal is delivered to the machine controller by detecting the end of travel, creating a pumping action.

Their rugged stainless steel housing is shrunk onto the ceramic sensing face for a gas-tight IP 68 seal.

These sensors are rated for more than 1 million pressure cycles, warranting their long-term reliability.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Inhibiting Imperfect Engagement during Automatic Tool Changes for Compact Machine-Tool Spindles Using Intelligent Inductive Sensors

Detecting the Status of Ram for Manual Punch-Riveting Instrument

Checking the Speed for Mobile Compost Turning Equipment

Related Products